Relocatable Buildings Army

- In addition to their flexibility to fulfill a wide variety of needs and specifications, Prefabricated Military Buildings offer several distinct advantages including:

- Weather Resistance. These Demountable army buildings are built to be wind- and water-tight.

- Durability. Military Metal Buildings are built with steel, designed to last 15-20 years with little or no maintenance required.

- Fast Deployment. When conditions permit, customers can place prefabricated army buildings directly on the ground without a concrete slab or in-ground foundation.

- Turnkey. Plug-and-play electrical and plumbing components are included in Military Prefab Buildings, significantly simplifying installation.

- Built-in Mobility. Demountable army buildings can be transported via ship, rail, or truck – and can be set up and relocated indefinitely without compromising their structural integrity.

| Roof System | |

| Steel frame | Steel frame is Q235 galvanized fitting; |

| Roof insulation | Ceiling is blue color steel pre-coated 0.4mm outside strong steel sheet; |

| With 50mm glass wool insulation material; | |

| Roof ceiling | Ceiling is shaped steel plate with different pattern |

| Floor System | |

| Steel frame | 3mm Galvanized Steel for main structure + 1.5mm square tube for secondary beam |

| Floor | 15mm chipboard + PVC leather floor |

| Column System | |

| Column | 2.5mm Shaped Galvanized Steel |

| Wall System | |

| Wall Panel | Material:Rock Wool/PU/PIR Sandwich Panel |

| Thickness:50mm/75mm/100mm | |

| Outside color is light silver gray (0.35mm thickness steel ); | |

| Inside is white color steel (0.35mm thickness steel ). | |

| Door & Window System | |

| One Door | Material: Steel door |

| Size:2000*980mm(H*W) | |

| Two Windows | Material:Aluminum alloy steel double hollow glass sliding window (including screens) |

| Size:1200*1000mm(H*W) | |

| Electric System | Includes: one ordinary LED light, A-SW double sockets 2set, A-SW air-switch 2 set, |

| Electrical box with safety protection device connecting cable for connecting; | |

| Accessories | Electric wire;Sealant;Wiring tube;Screws and other accessories. |

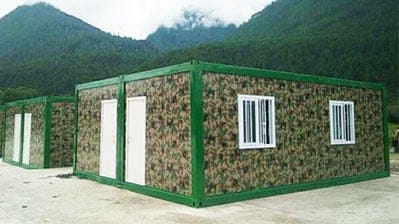

Prefabricated Military Buildings

Prefabricated Military Buildings as the Modular Barracks Solutions, not only can move and scale with military operations but are manufactured to International Organization for Standardization’s (ISO) standards. Portable army buildings are easy to transport and usually require no over-size trucking permits. Demountable army buildings are remarkably durable, cost-effective, and save a lot of construction time.

Our container house is detachable. When the office location needs to be changed due to military tasks, such a modular container house can be easily moved to a new location. Our detachable container houses have provided strong support for military barracks construction and development in various periods. The use of containers as the main body of the building is the general trend in the construction of large and medium-sized military barracks bases in the world. The container houses adapt to the continuous development and change of the combat style, group training mode, and support method of the army.

Modular Barracks Application

- Demountable army buildings are durable enough to be shipped to remote locations and ensure the occupants feel comfortable and safe.

- Teams can meet to discuss events and training in an air-conditioned prefab army container. Whiteboards and desks can be added to create a classroom environment.

- Single, double, and triple wide workspaces with attached modular container house can be disassembled and relocated as operational needs change.

- Demountable army buildings are durable enough to be shipped to remote locations and ensure the occupants feel comfortable and safe.

- Modular container houses are widely used in the military, such as military barracks, soldier camps, military command centers, temporary hospitals, material storage rooms, soldier canteens, laundry rooms, public toilets, etc.

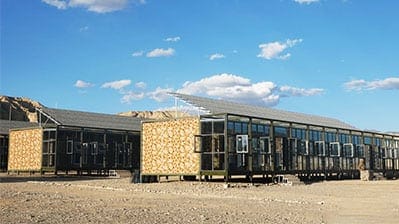

Modular Army Building

The importance of army building to a country is self-evident. Every country attaches great importance to and invests a lot of manpower and material resources. The reusable container house not only meets the daily needs of the military in function but also saves costs due to its environmentally friendly and mobile advantages. The modular container house is a kind of temporary building, and its standardized and flexible design is deeply loved by customers.

The size of our K-Home standard container size is 3×6×2.8m. It can be combined horizontally or vertically to form a larger space, which can be used as homes, offices, dormitories, camps, etc. Because the components of the container units are all manufactured in the factory and transported to the construction site to be assembled. Packing, not only saved the shipping containers but also protect the products very well. There will be no damage during transportation.

The whole set of transportation systems was thus established. It can standardize a behemoth with a load of tens of tons, which greatly reduces transportation costs for customers. The scope of application of container houses in the military is increasing. The customized container design helps to enhance the mobility of military dispatch, shorten the deployment time of equipment, and enhance logistic support. The army’s use of containers has expanded from temporary command posts to field houses.

The modular container buildings used in the military have been strictly controlled. As we know, the structural design of the container house, durability, thermal insulation, quality, and resistance to weather conditions for the building are very important. Our K-Home has two major product lines. The entire production is carried out under strict quality control. We can provide you with a quality certificate before delivery. In addition, we will make the tags for the main structure in our factory to ensure a smooth installation on your site.

Advantages of Relocatable Army Containers

- Save transportation and storage space

A standard container unit can form a temporary house with a standard 20ft shipping container space, which can be packaged into a 1/4 volume package of a standard 20ft shipping container. Four such packages are packed together, which is equivalent to the volume of a 20ft shipping container. It can be directly used for sea and land transportation. It is sturdy and convenient. A 20ft shipping container can load 4 sets of our container units, and a 40ft shipping container can load 11 sets. In the process of transportation and storage, space is greatly saved, thereby reducing transportation and storage costs. - Quick installation

Factory pre-assembled to minimize the workload on site. The sandwich panels and steel columns of the standard container units are all completed in the factory. On the site, only the columns and wall panels need to be bolted to the bottom and top frame, and the line clamps are inserted in sequence, A room of 18 square meters was completed. This reduces the workload on-site to a minimum. - Good fire resistance and sound insulation effect

The roof insulation layer is glass wool, which has excellent thermal insulation and fireproof performance. The wall is made of rock wool sandwich panels. This material not only has high strength and good thermal insulation performance but also has good fire resistance and flame retardant performance, reaching A1 level. Sealing strips are added to some parts of the module room to achieve good airtightness. The gap between the roof and the ground achieves a noise reduction function, and the rock wool sandwich panels in the wall panels are also a good sound insulation material. - Sturdy and Strong

The mainframe of the container house has a steel structure, which is connected by high-strength bolts to form a high-strength overall structure that can withstand earthquakes and typhoons. - Modular design

The container house adopts modular designs, which can be connected and expanded infinitely. The modular container house can be vertically connected with 3 floors/horizontally infinitely connected; the overall surface of the house can be adjusted during the use of the project. The design is flexible and changeable. Because the units house adopts modular designs, it can be replaced with standard parts if it is damaged as large as the top frame and the bottom frame, which is conducive to maintenance. - Short delivery time

Production and on-site preparation work are carried out at the same time, convenient installation, long product life, safe and environmentally friendly, and sustainable use. The prefabricated modular container realizes no rubbish for on-site installation. Lean management and standardization limit the generation of waste in the production process. The noiseless module house, quick installation, quick removal after the project, and portable and removable advantages all limit the impact on the site environment - Performance advantage

Container houses have many performance advantages, such as high sealing and safety, waterproof, windproof, fireproof, anti-corrosion, cold-proof, shockproof, sound insulation, heat insulation, and repeated use. Improve and improve the comfort and safety of attributes. It can be designed in various shapes, with many designs and colors on the outer wall, and the appearance is bright and beautiful.

Related Products

Project Show

Recent Blogs

SEND A MESSAGE