T-type Prefabricated House

K-HOME is your one-stop shop for customizing prefabricated houses.

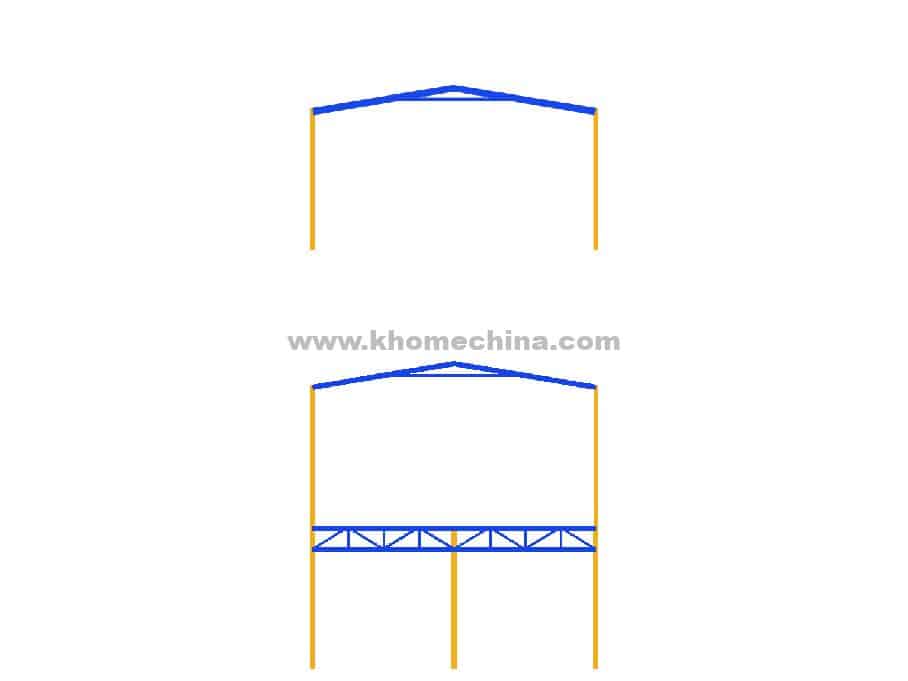

Different types of T-type prefabricated houses

You can see some comparisons in this article, click the picture below to learn more details

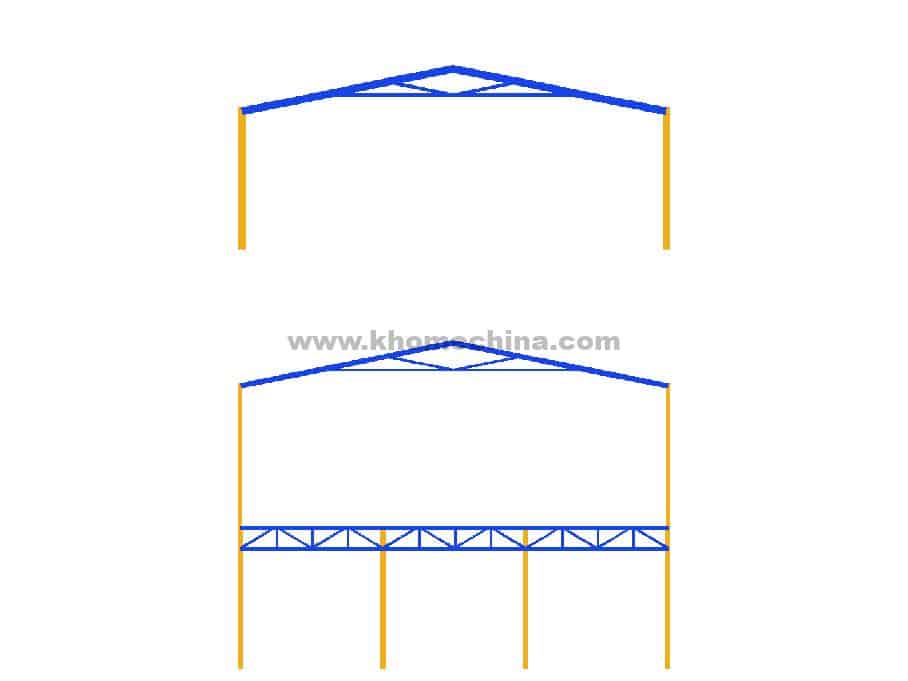

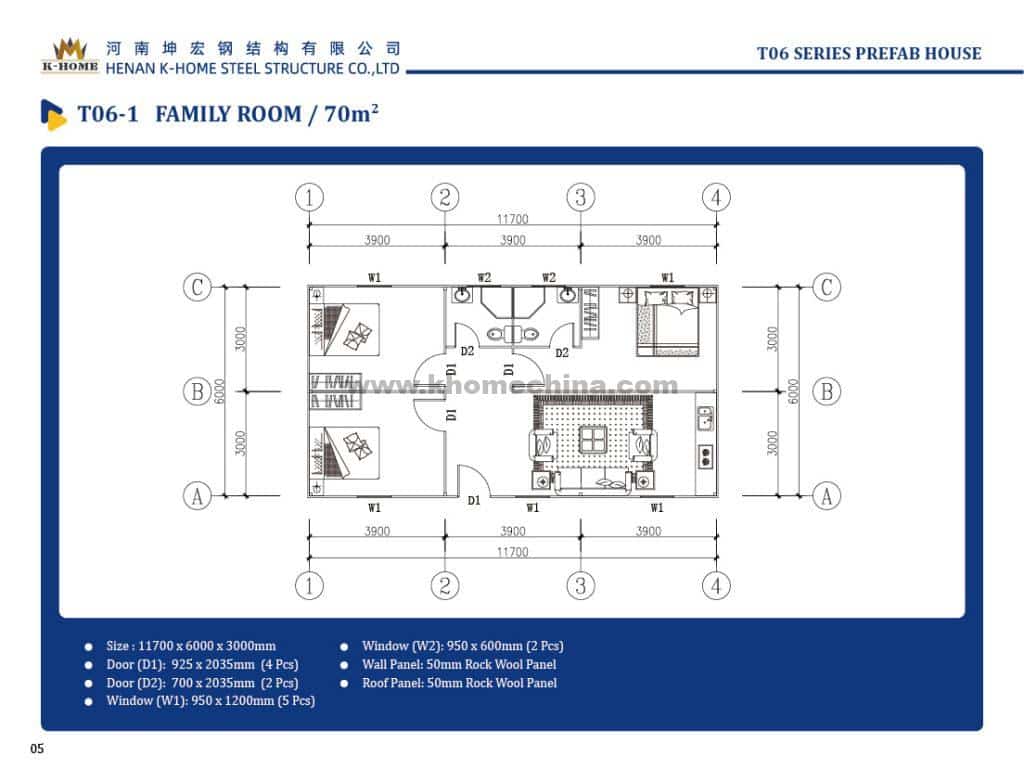

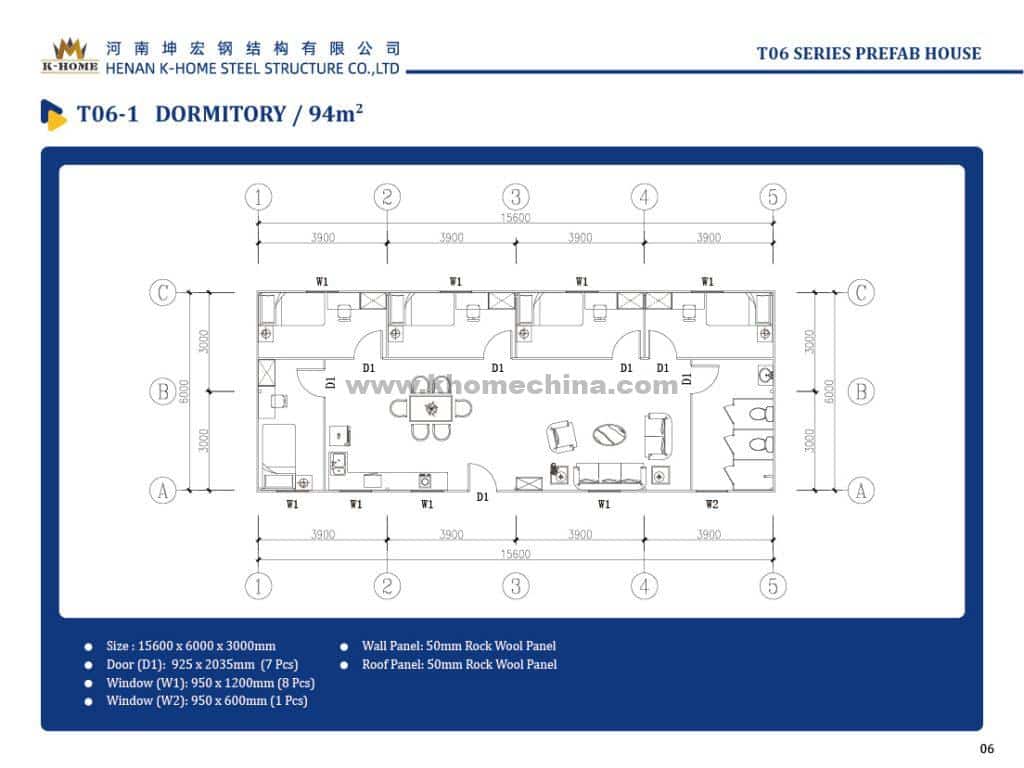

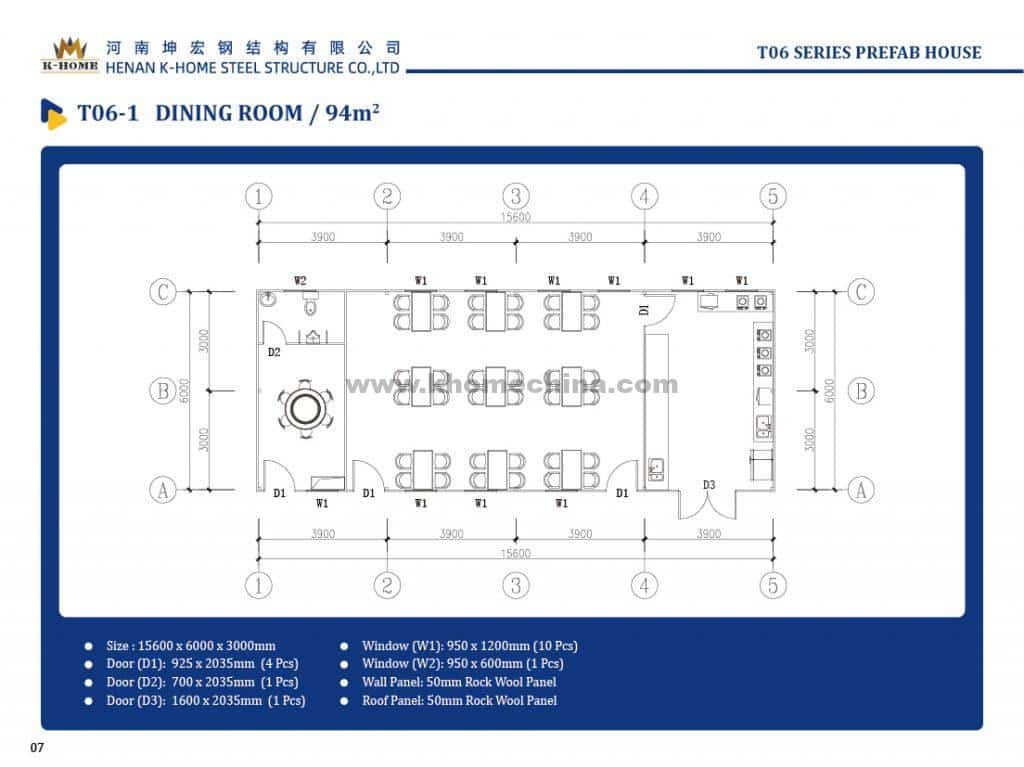

T06

Max Width: 6000MM

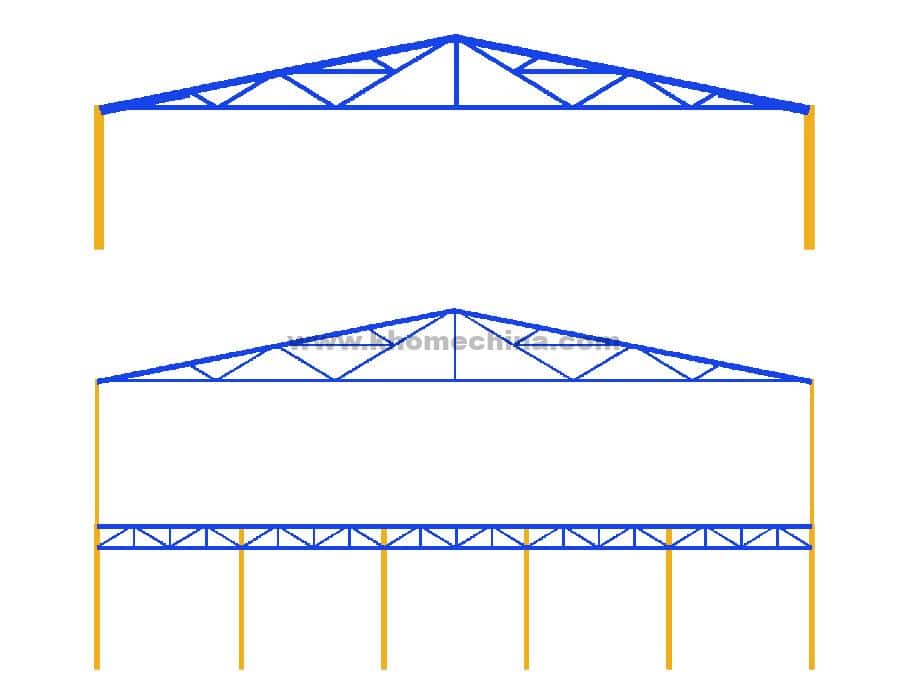

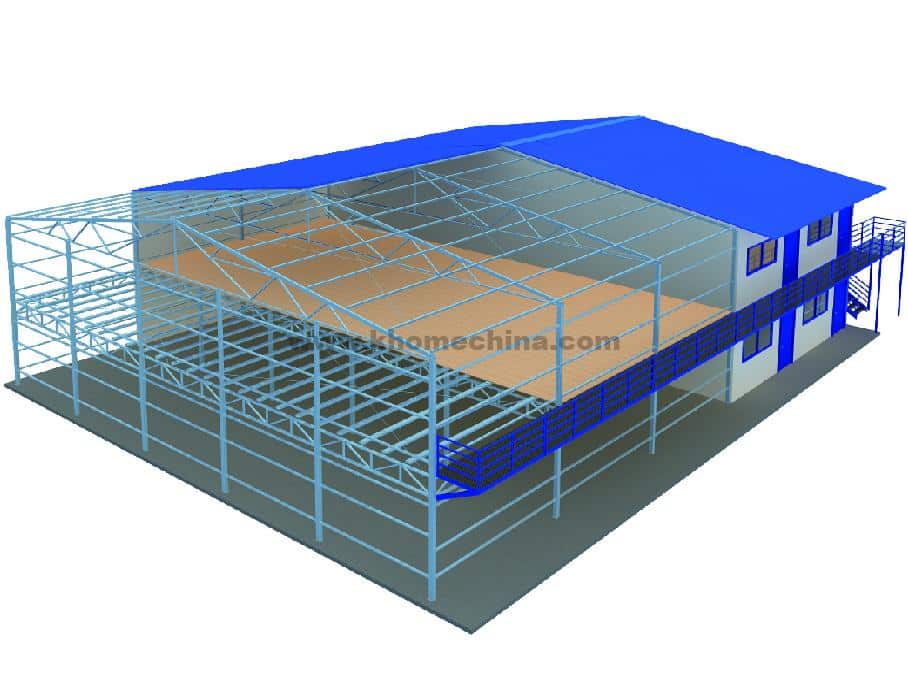

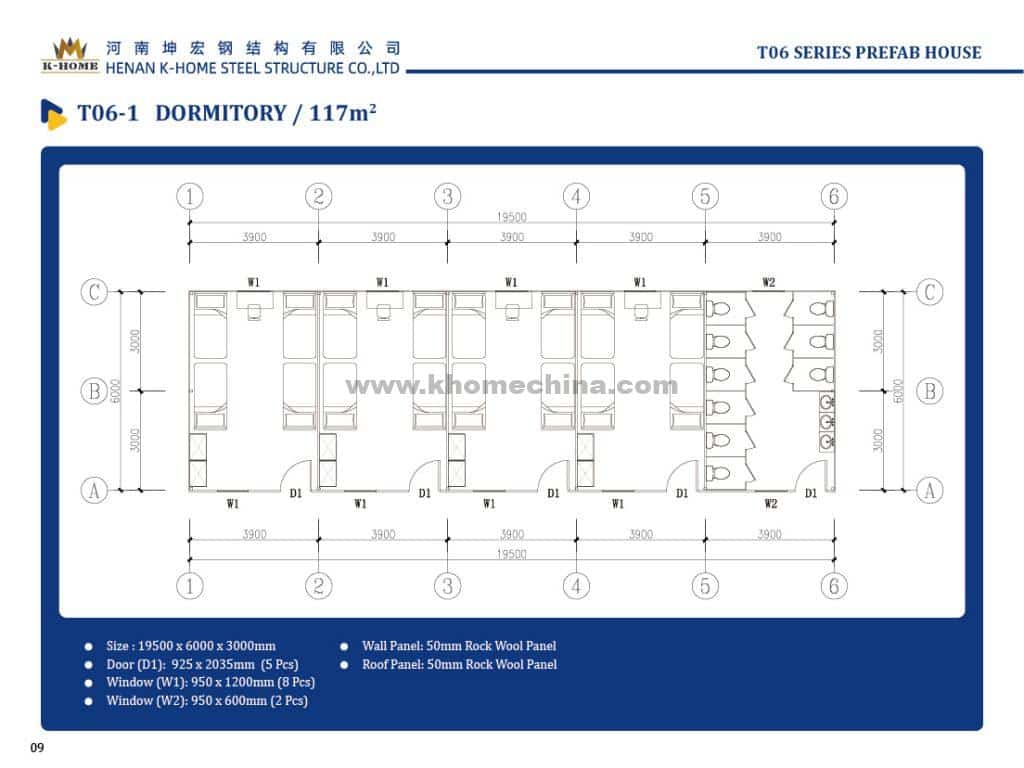

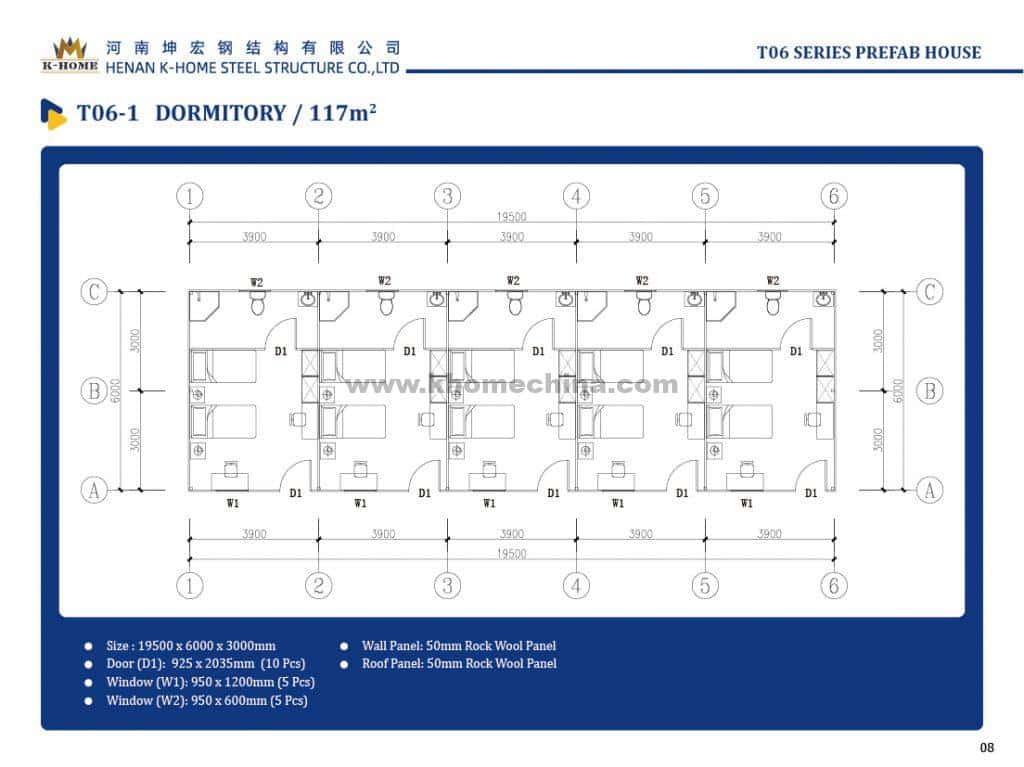

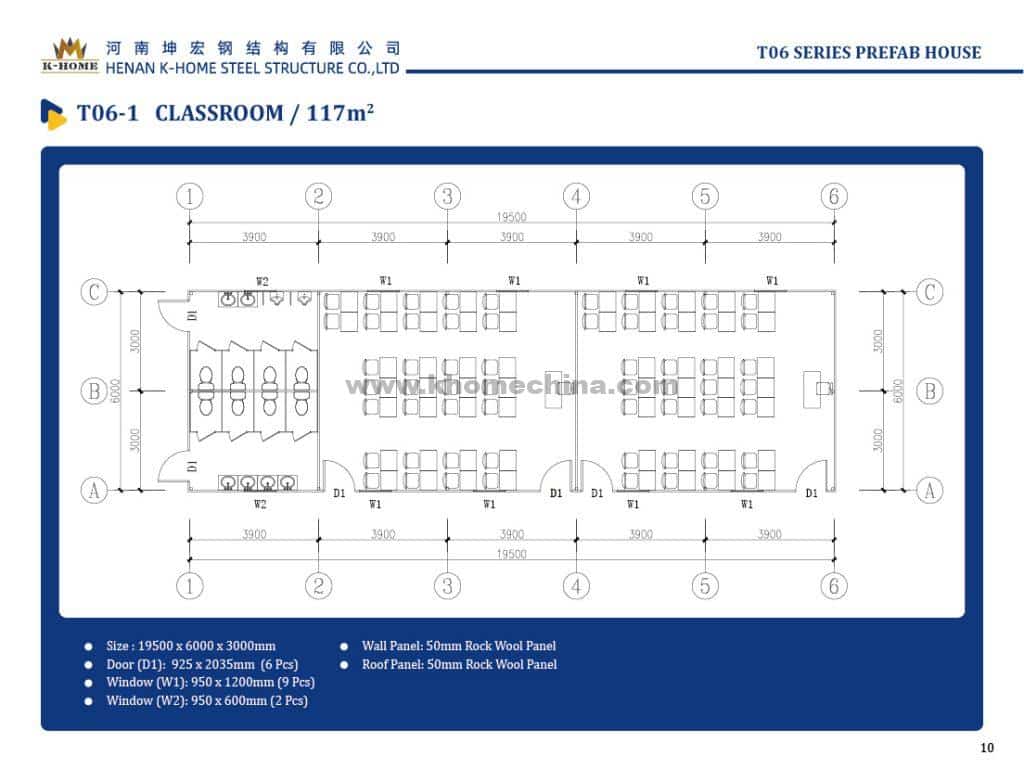

T06-1 Prefabricated House Parameters

| T06-1 | Items | Description | |

|---|---|---|---|

| Prefabricated House Size | Max Width: | 6000mm | |

| Column Height: | 3000mm | ||

| Length: | Customizable | ||

| Column Spacing: | 3900mm | ||

| Layers: | Single-layer | ||

| Design Parameters (Standard) | Roof Dead Load: | 0.1 KN/m2 | |

| Roof Live Load: | 0.1 KN/m2 | ||

| Wind Load: | 0.18 KN/m2 (61km/h) | ||

| Earthquake Resistance: | 8-grade | ||

| Steel Structure Framework | Column: | Wind Column: | 80x40x2.0mm Galvanized Square Tube |

| Column: | 80x80x2.0mm Galvanized Square Tube | ||

| Roof Truss: | Top Chord: | 100x50x2.0mm Galvanized Square Tube | |

| Web Member: | 40x40x2.0mm Galvanized Square Tube | ||

| Purlins: | Wind Purlins: | 60x40x1.5mm Galvanized Square Tube | |

| Wall Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Roof Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

T06-2 Prefabricated House Parameters

| T06-2 | Items | Description | |

|---|---|---|---|

| Prefabricated House Size | Max Width: | 6000mm | |

| First Floor Column Height: | 3000mm | ||

| Second Floor Column Height: | 2800mm | ||

| Length: | Customizable | ||

| Column Spacing: | 3900mm | ||

| Layers: | Double-layer | ||

| Design Parameters (Standard) | Roof Dead Load: | 0.1 KN/m2 | |

| Roof Live Load: | 0.1 KN/m2 | ||

| Floor Dead Load: | 0.6 KN/m2 | ||

| Floor Live Load: | 2.0 KN/m2 | ||

| Wind Load: | 0.18 KN/m2 (61km/h) | ||

| Earthquake Resistance: | 8-grade | ||

| Steel Structure Framework | Steel Column: | Wind Column: | 80x40x2.0mm Galvanized Square Tube |

| First Floor Column: | 100x100x2.5mm Galvanized Square Tube | ||

| First Floor Internal Column: | 100x100x2.5mm Galvanized Square Tube | ||

| Second Floor Column: | 80x80x2.0mm Galvanized Square Tube | ||

| Steel Roof Truss: | Top Chord: | 100x50x2.0mm Galvanized Square Tube | |

| Web Member: | 40x40x2.0mm Galvanized Square Tube | ||

| Steel Floor Truss: | Top Chord: | 80x40x2.0mm Galvanized Square Tube | |

| Bottom Chord: | 80x40x2.0mm Galvanized Square Tube | ||

| Web Member: | 40x40x2.0mm Galvanized Square Tube | ||

| Steel Purlins: | Wind Purlins: | 60x40x1.5mm Galvanized Square Tube | |

| Wall Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Roof Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Floor Purlins: | 120x60x2.5mm Galvanized Square Tube | ||

| Bracing: | Ф12mm | ||

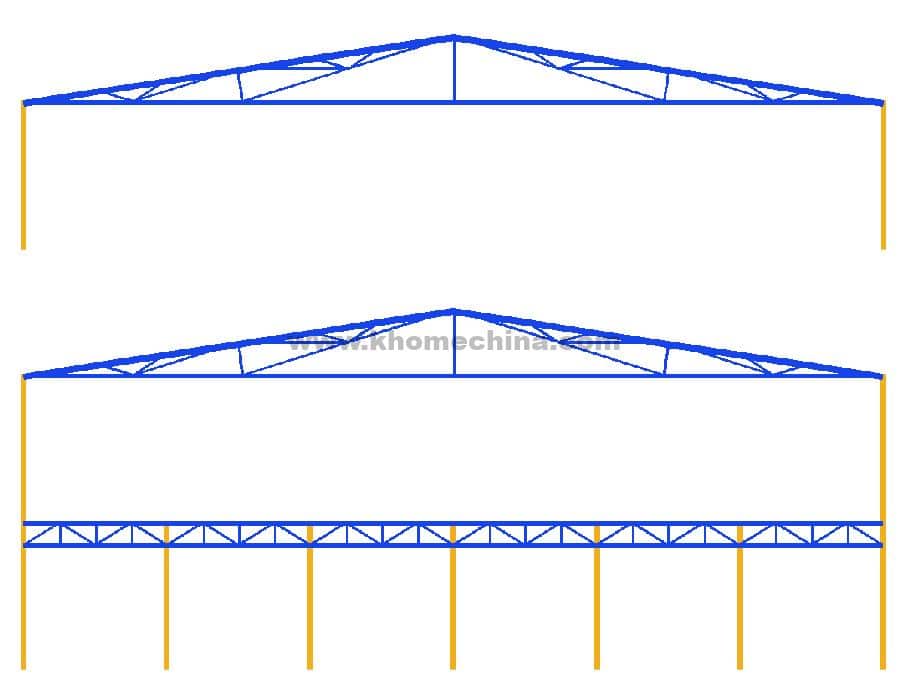

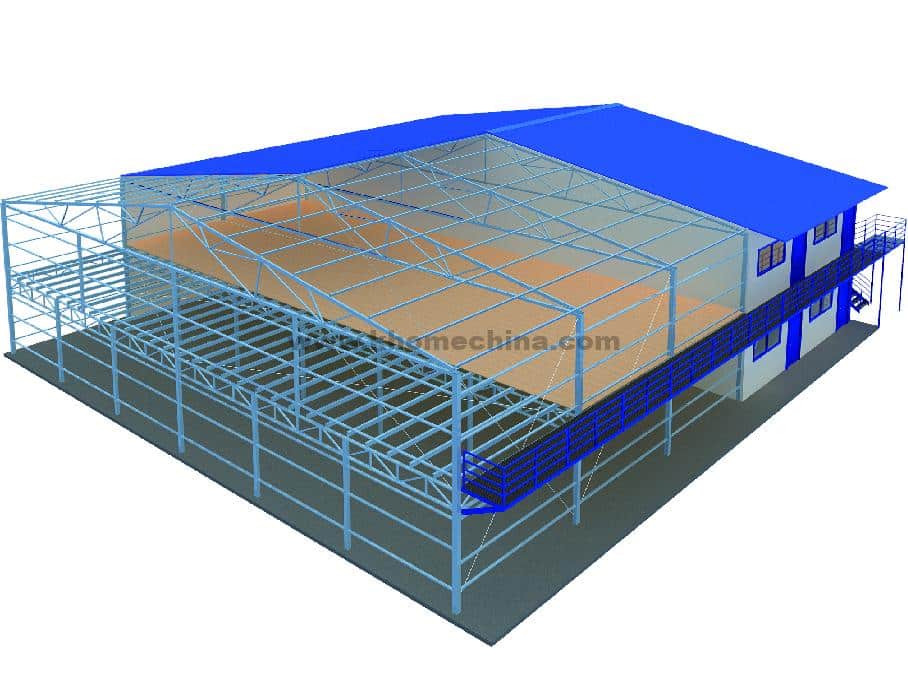

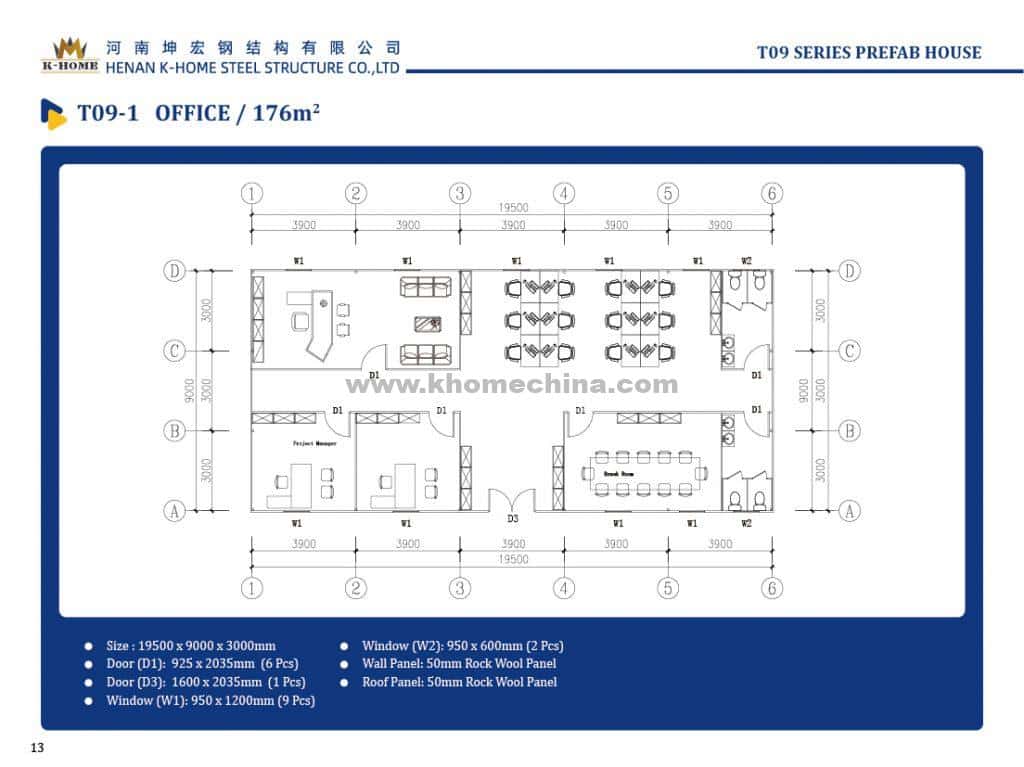

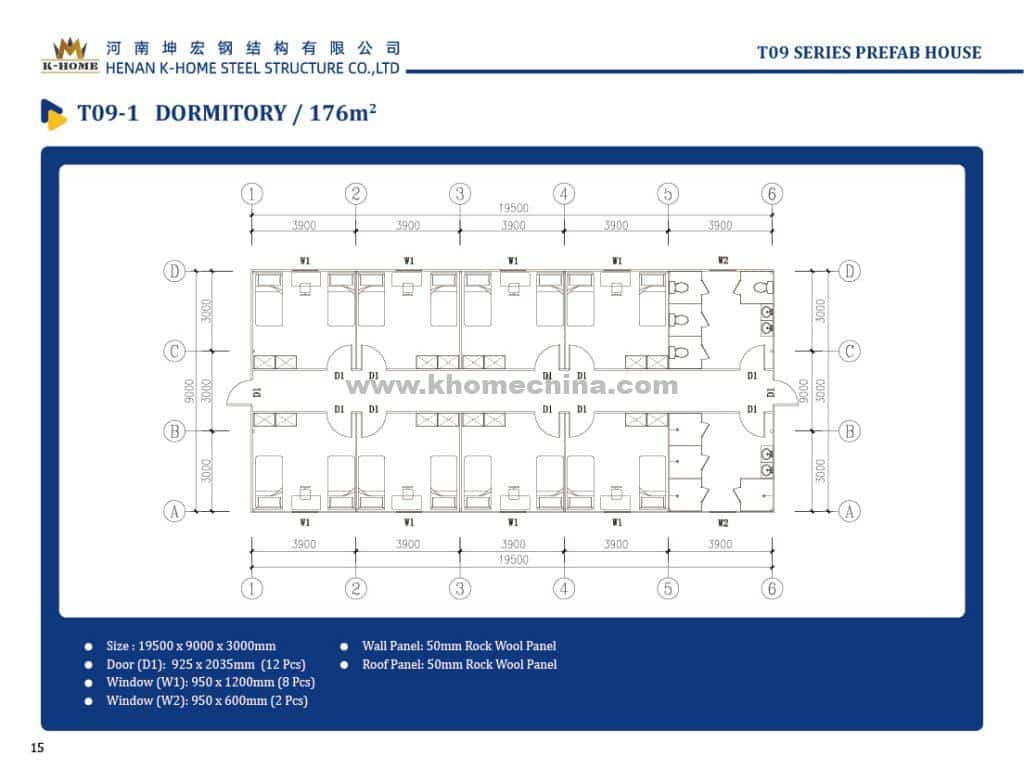

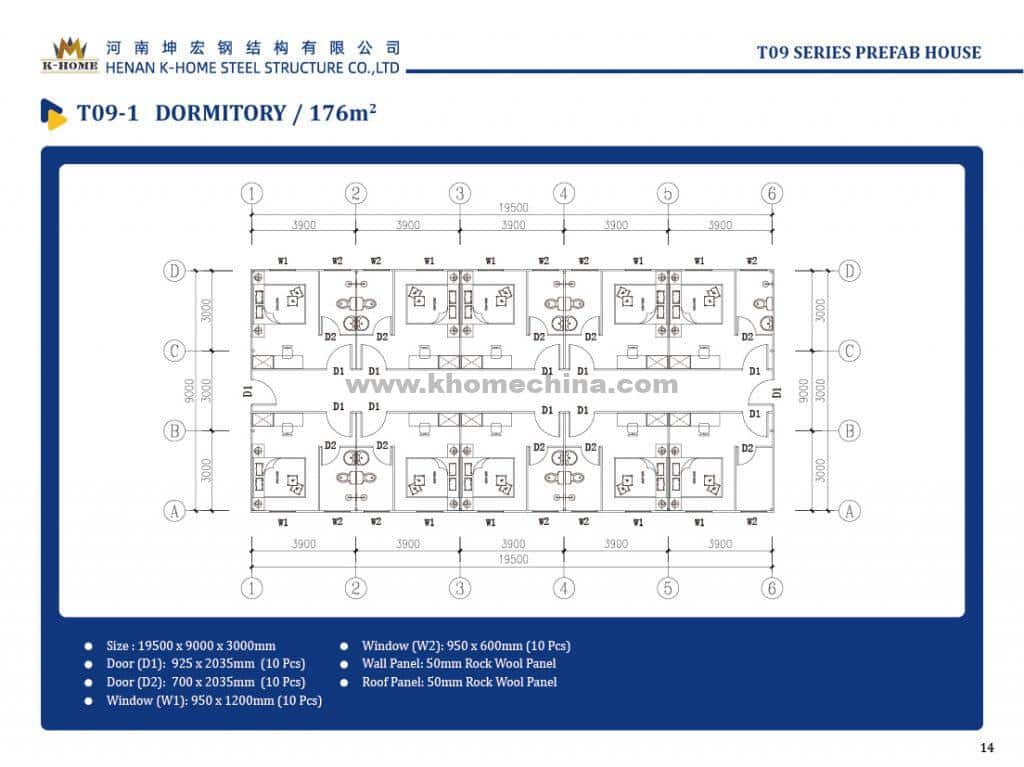

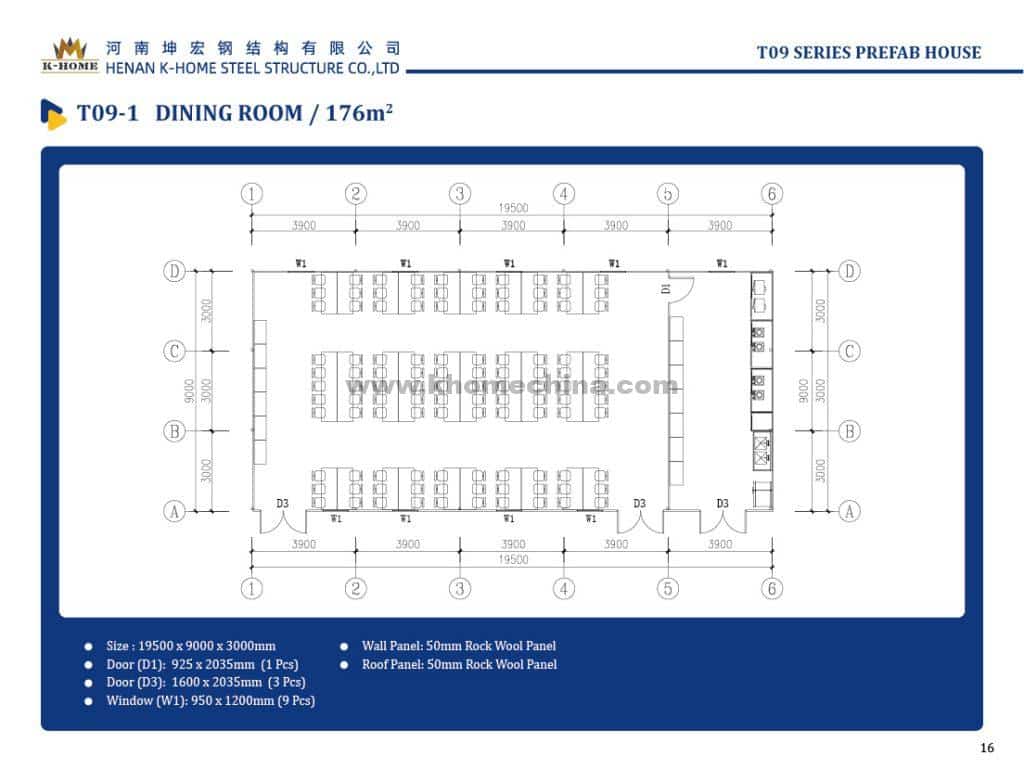

T09-1 Prefabricated House Parameters

| T09-1 | Items | Description | |

|---|---|---|---|

| Prefabricated House Size | Max Width: | 9000mm | |

| Column Height: | 3000mm | ||

| Length: | Customizable | ||

| Column Spacing: | 3900mm | ||

| Layers: | Single-layer | ||

| Design Parameters (Standard) | Roof Dead Load: | 0.1 KN/m2 | |

| Roof Live Load: | 0.1 KN/m2 | ||

| Wind Load: | 0.18 KN/m2 (61km/h) | ||

| Earthquake Resistance: | 8-grade | ||

| Steel Structure Framework | Column: | Wind Column: | 80x80x2.0mm Galvanized Square Tube |

| Column: | 80x80x2.5mm Galvanized Square Tube | ||

| Roof Truss: | Top Chord: | 100x50x2.0mm Galvanized Square Tube | |

| Web Member: | 40x40x2.0mm Galvanized Square Tube | ||

| Purlins: | Wind Purlins: | 60x40x1.5mm Galvanized Square Tube | |

| Wall Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Roof Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Bracing: | Ф12mm | ||

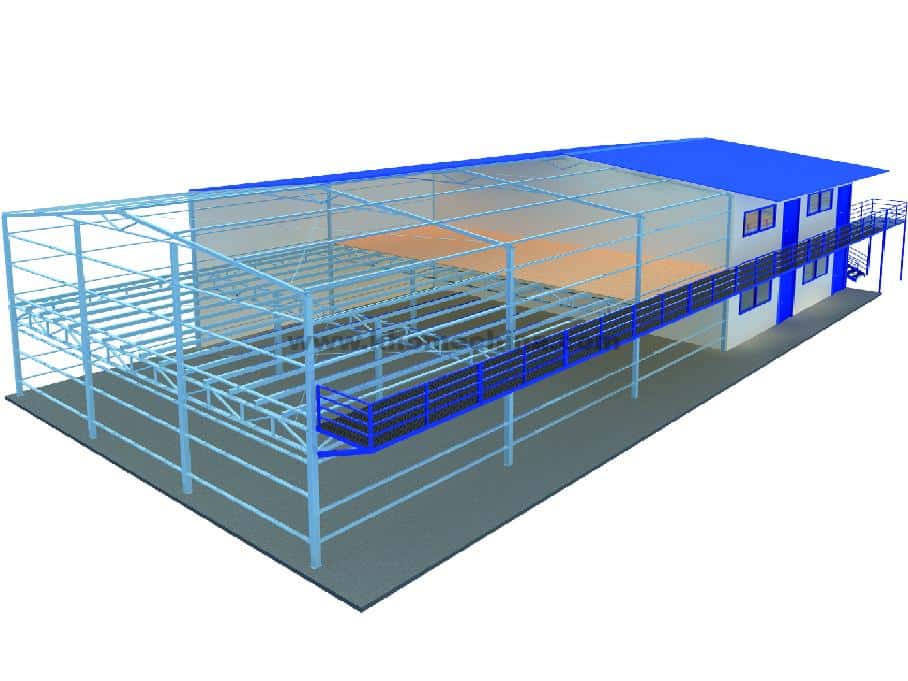

T09-2 Prefabricated House Parameters

| T09-2 | Items | Description | |

|---|---|---|---|

| Prefabricated House Size | Max Width: | 9000mm | |

| First Floor Column Height: | 3000mm | ||

| Second Floor Column Height: | 2800mm | ||

| Length: | Customizable | ||

| Column Spacing: | 3900mm | ||

| Layers: | Double-layer | ||

| Design Parameters (Standard) | Roof Dead Load: | 0.1 KN/m2 | |

| Roof Live Load: | 0.1 KN/m2 | ||

| Floor Dead Load: | 0.6 KN/m2 | ||

| Floor Live Load: | 2.0 KN/m2 | ||

| Wind Load: | 0.18 KN/m2 (61km/h) | ||

| Earthquake Resistance: | 8-grade | ||

| Steel Structure Framework | Steel Column: | Wind Column: | 80x80x2.0mm Galvanized Square Tube |

| First Floor Column: | 100x100x2.5mm Galvanized Square Tube | ||

| First Floor Internal Column: | 100x100x2.5mm Galvanized Square Tube | ||

| Second Floor Column: | 80x80x2.5mm Galvanized Square Tube | ||

| Steel Roof Truss: | Top Chord: | 100x50x2.0mm Galvanized Square Tube | |

| Web Member: | 40x40x2.0mm Galvanized Square Tube | ||

| Steel Floor Truss: | Top Chord: | 80x40x2.0mm Galvanized Square Tube | |

| Bottom Chord: | 80x40x2.0mm Galvanized Square Tube | ||

| Web Member: | 40x40x2.0mm Galvanized Square Tube | ||

| Steel Purlins: | Wind Purlins: | 60x40x1.5mm Galvanized Square Tube | |

| Wall Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Roof Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Floor Purlins: | 120x60x2.5mm Galvanized Square Tube | ||

| Bracing: | Ф12mm | ||

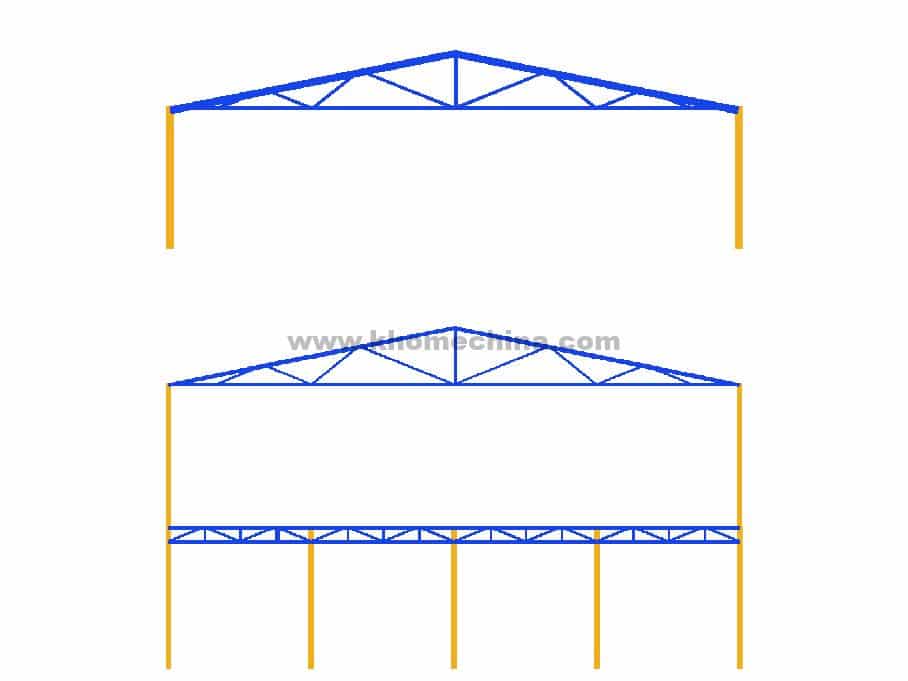

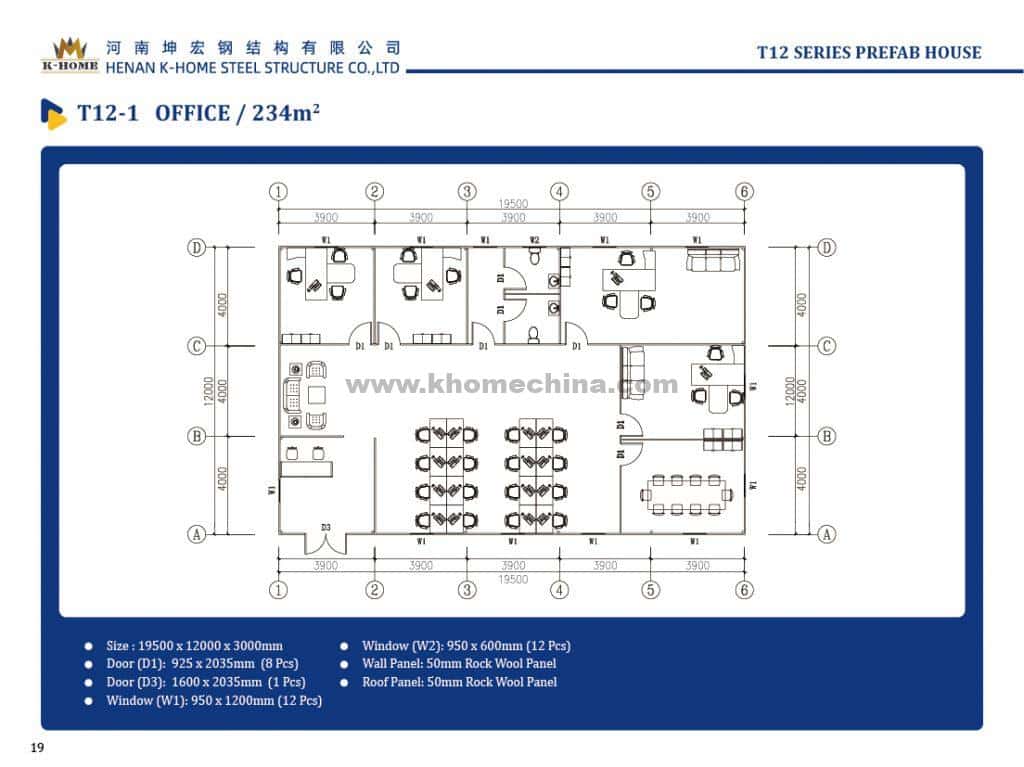

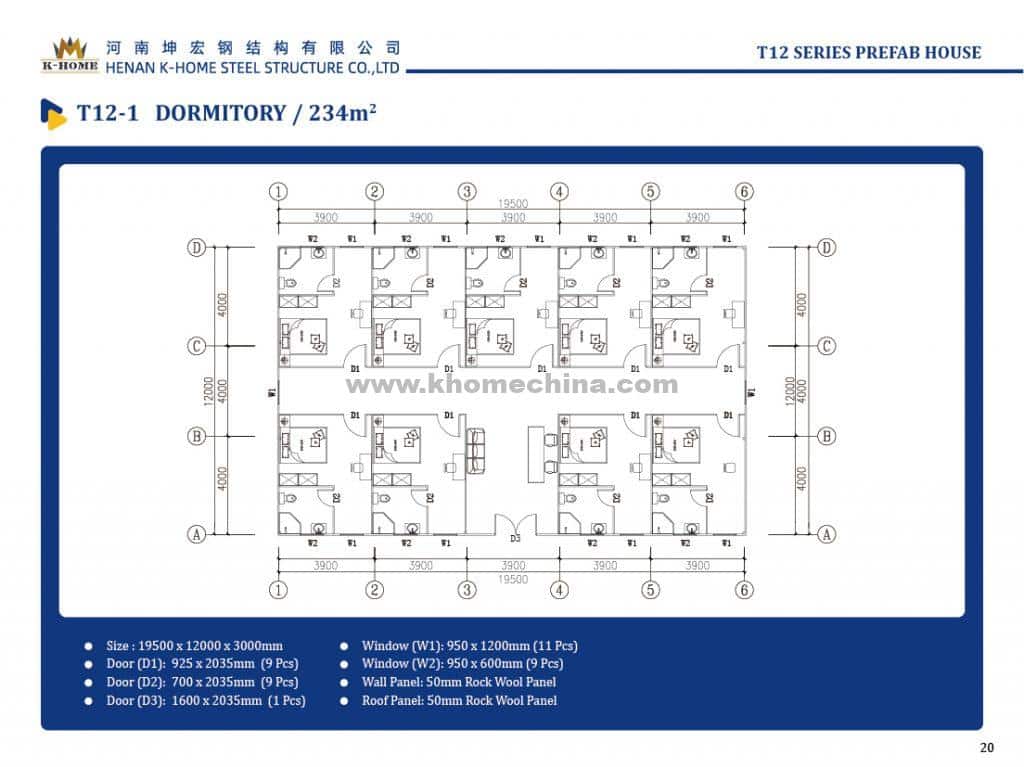

T12-1 Prefabricated House Parameters

| T12-1 | Items | Description | |

|---|---|---|---|

| Prefabricated House Size | Max Width: | 12000mm | |

| Column Height: | 3000mm | ||

| Length: | Customizable | ||

| Column Spacing: | 3900mm | ||

| Layers: | Single-layer | ||

| Design Parameters (Standard) | Roof Dead Load: | 0.1 KN/m2 | |

| Roof Live Load: | 0.1 KN/m2 | ||

| Wind Load: | 0.18 KN/m2 (61km/h) | ||

| Earthquake Resistance: | 8-grade | ||

| Steel Structure Framework | Column: | Wind Column: | 80x80x2.0mm Galvanized Square Tube |

| Column: | 80x80x2.5mm Galvanized Square Tube | ||

| Roof Truss: | Top Chord: | 100x50x2.0mm Galvanized Square Tube | |

| Bottom Chord: | 40x40x2.0mm Galvanized Square Tube | ||

| Web Member: | 40x40x2.0mm Galvanized Square Tube | ||

| Purlins: | Wind Purlins: | 60x40x1.5mm Galvanized Square Tube | |

| Wall Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Roof Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Bracing: | Ф12mm | ||

T12-2 Prefabricated House Parameters

| T12-2 | Items | Description | |

|---|---|---|---|

| Prefabricated House Size | Max Width: | 12000mm | |

| First Floor Column Height: | 3000mm | ||

| Second Floor Column Height: | 2800mm | ||

| Length: | Customizable | ||

| Column Spacing: | 3900mm | ||

| Layers: | Double-layer | ||

| Design Parameters (Standard) | Roof Dead Load: | 0.1 KN/m2 | |

| Roof Live Load: | 0.1 KN/m2 | ||

| Floor Dead Load: | 0.6 KN/m2 | ||

| Floor Live Load: | 2.0 KN/m2 | ||

| Wind Load: | 0.18 KN/m2 (61km/h) | ||

| Earthquake Resistance: | 8-grade | ||

| Steel Structure Framework | Steel Column: | Wind Column: | 80x80x2.0mm Galvanized Square Tube |

| First Floor Column: | 100x100x2.5mm Galvanized Square Tube | ||

| First Floor Internal Column: | 100x100x2.5mm Galvanized Square Tube | ||

| Second Floor Column: | 80x80x2.5mm Galvanized Square Tube | ||

| Steel Roof Truss: | Top Chord: | 100x50x2.0mm Galvanized Square Tube | |

| Bottom Chord: | 40x40x2.0mm Galvanized Square Tube | ||

| Web Member: | 40x40x2.0mm Galvanized Square Tube | ||

| Steel Floor Truss: | Top Chord: | 80x40x2.0mm Galvanized Square Tube | |

| Bottom Chord: | 80x40x2.0mm Galvanized Square Tube | ||

| Web Member: | 40x40x2.0mm Galvanized Square Tube | ||

| Steel Purlins: | Wind Purlins: | 60x40x1.5mm Galvanized Square Tube | |

| Wall Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Roof Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Floor Purlins: | 120x60x2.5mm Galvanized Square Tube | ||

| Bracing: | Ф12mm | ||

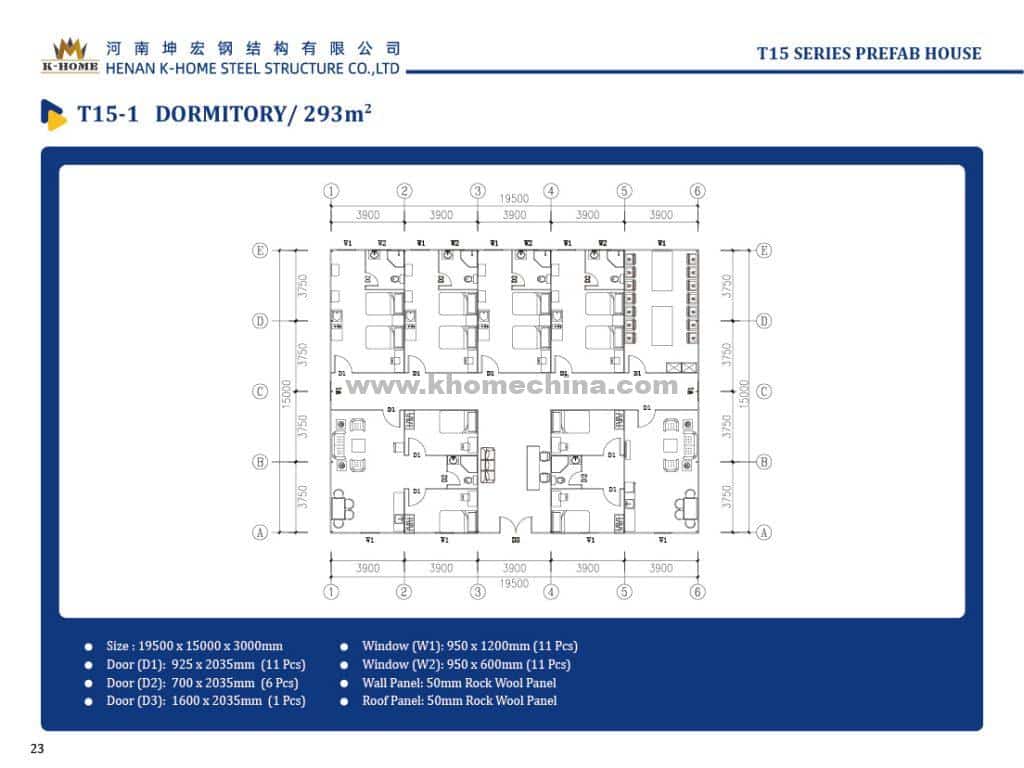

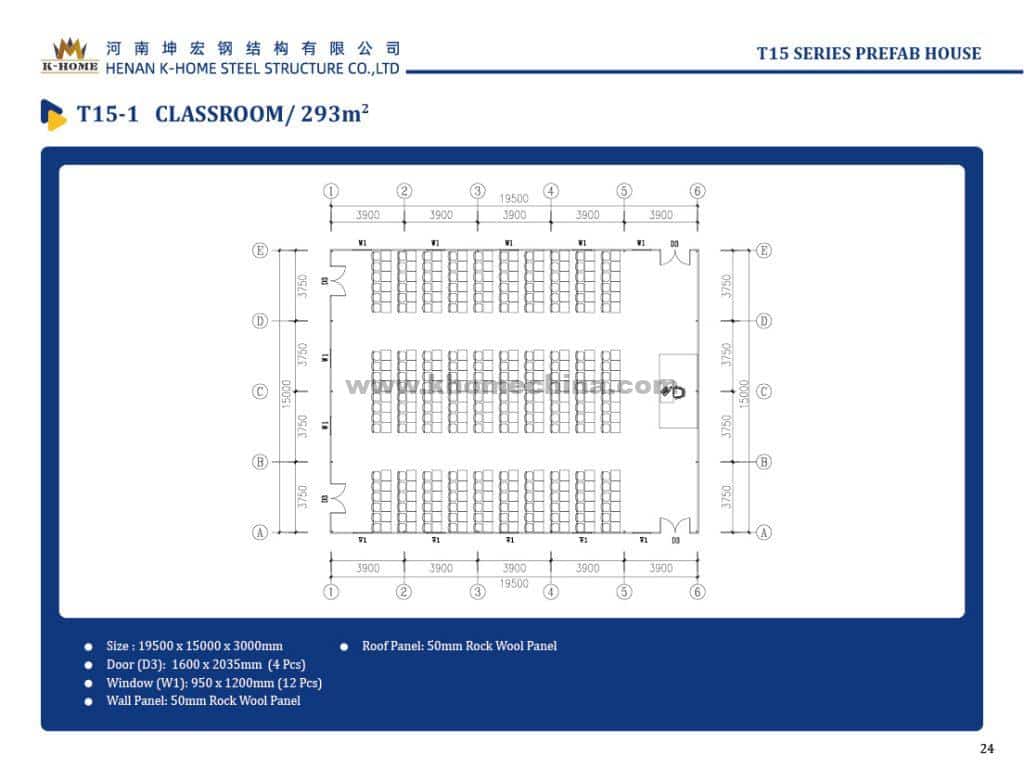

T15-1 Prefabricated House Parameters

| T15-1 | Items | Description | |

|---|---|---|---|

| Prefabricated House Size | Max Width: | 15000mm | |

| Column Height: | 3000mm | ||

| Length: | Customizable | ||

| Column Spacing: | 3900mm | ||

| Layers: | Single-layer | ||

| Design Parameters (Standard) | Roof Dead Load: | 0.1 KN/m2 | |

| Roof Live Load: | 0.1 KN/m2 | ||

| Wind Load: | 0.18 KN/m2 (61km/h) | ||

| Earthquake Resistance: | 8-grade | ||

| Steel Structure Framework | Column: | Wind Column: | 80x80x2.0mm Galvanized Square Tube |

| Column: | 100x100x2.5mm Galvanized Square Tube | ||

| Roof Truss: | Top Chord: | 100x50x2.0mm Galvanized Square Tube | |

| Bottom Chord: | 40x40x2.0mm Galvanized Square Tube | ||

| Web Member: | 40x40x2.0mm Galvanized Square Tube | ||

| Purlins: | Wind Purlins: | 60x40x1.5mm Galvanized Square Tube | |

| Wall Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Roof Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Bracing: | Ф12mm | ||

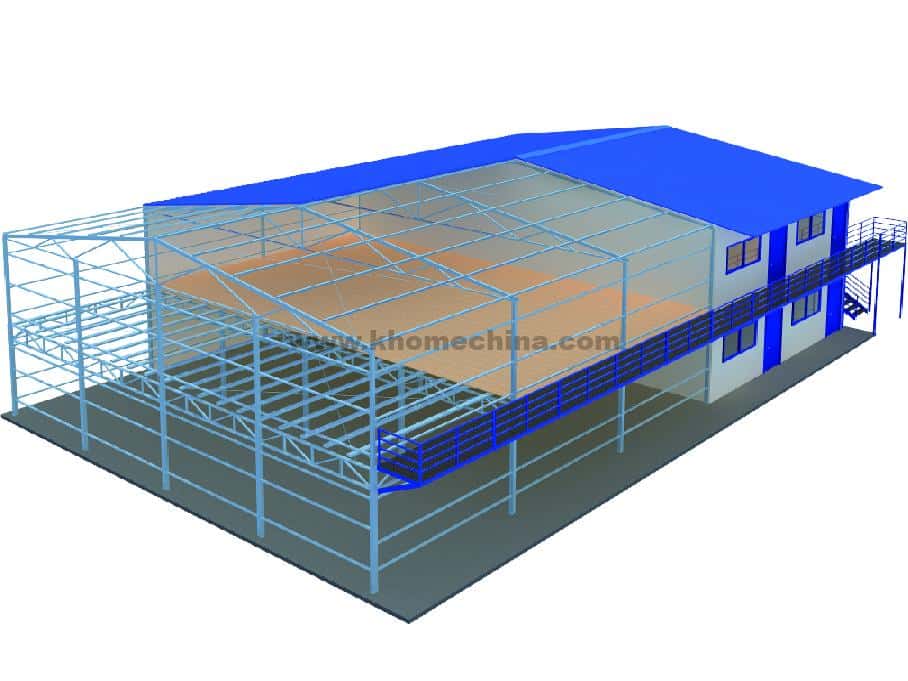

T15-2 Prefabricated House Parameters

| T15-2 | Items | Description | |

|---|---|---|---|

| Prefabricated House Size | Max Width: | 15000mm | |

| First Floor Column Height: | 3000mm | ||

| Second Floor Column Height: | 2800mm | ||

| Length: | Customizable | ||

| Column Spacing: | 3900mm | ||

| Layers: | Double-layer | ||

| Design Parameters (Standard) | Roof Dead Load: | 0.1 KN/m2 | |

| Roof Live Load: | 0.1 KN/m2 | ||

| Floor Dead Load: | 0.6 KN/m2 | ||

| Floor Live Load: | 2.0 KN/m2 | ||

| Wind Load: | 0.18 KN/m2 (61km/h) | ||

| Earthquake Resistance: | 8-grade | ||

| Steel Structure Framework | Steel Column: | Wind Column: | 80x80x2.0mm Galvanized Square Tube |

| First Floor Column: | 100x100x2.5mm Galvanized Square Tube | ||

| First Floor Internal Column: | 100x100x2.5mm Galvanized Square Tube | ||

| Second Floor Column: | 100x100x2.5mm Galvanized Square Tube | ||

| Steel Roof Truss: | Top Chord: | 100x50x2.0mm Galvanized Square Tube | |

| Bottom Chord: | 40x40x2.0mm Galvanized Square Tube | ||

| Web Member: | 40x40x2.0mm Galvanized Square Tube | ||

| Steel Floor Truss: | Top Chord: | 80x40x2.0mm Galvanized Square Tube | |

| Bottom Chord: | 80x40x2.0mm Galvanized Square Tube | ||

| Web Member: | 40x40x2.0mm Galvanized Square Tube | ||

| Steel Purlins: | Wind Purlins: | 60x40x1.5mm Galvanized Square Tube | |

| Wall Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Roof Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Floor Purlins: | 120x60x2.5mm Galvanized Square Tube | ||

| Bracing: | Ф12mm | ||

T18-1 Prefabricated House Parameters

| T18-1 | Items | Description | |

|---|---|---|---|

| Prefabricated House Size | Max Width: | 18000mm | |

| Column Height: | 3000mm | ||

| Length: | Customizable | ||

| Column Spacing: | 3900mm | ||

| Layers: | Single-layer | ||

| Design Parameters (Standard) | Roof Dead Load: | 0.1 KN/m2 | |

| Roof Live Load: | 0.1 KN/m2 | ||

| Wind Load: | 0.18 KN/m2 (61km/h) | ||

| Earthquake Resistance: | 8-grade | ||

| Steel Structure Framework | Column: | Wind Column: | 80x80x2.0mm Galvanized Square Tube |

| Column: | 120x120x2.5mm Galvanized Square Tube | ||

| Roof Truss: | Top Chord: | 120x60x2.5mm Galvanized Square Tube | |

| Bottom Chord: | 80x80x2.0mm Galvanized Square Tube | ||

| Web Member: | 40x40x2.0mm Galvanized Square Tube | ||

| Purlins: | Wind Purlins: | 60x40x1.5mm Galvanized Square Tube | |

| Wall Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Roof Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Bracing: | Ф12mm | ||

T18-2 Prefabricated House Parameters

| T18-2 | Items | Description | |

|---|---|---|---|

| Prefabricated House Size | Max Width: | 18000mm | |

| First Floor Column Height: | 3000mm | ||

| Second Floor Column Height: | 2800mm | ||

| Length: | Customizable | ||

| Column Spacing: | 3900mm | ||

| Layers: | Double-layer | ||

| Design Parameters (Standard) | Roof Dead Load: | 0.1 KN/m2 | |

| Roof Live Load: | 0.1 KN/m2 | ||

| Floor Dead Load: | 0.6 KN/m2 | ||

| Floor Live Load: | 2.0 KN/m2 | ||

| Wind Load: | 0.18 KN/m2 (61km/h) | ||

| Earthquake Resistance: | 8-grade | ||

| Steel Structure Framework | Steel Column: | Wind Column: | 80x80x2.0mm Galvanized Square Tube |

| First Floor Column: | 120x120x2.5mm Galvanized Square Tube | ||

| First Floor Internal Column: | 100x100x2.5mm Galvanized Square Tube | ||

| Second Floor Column: | 120x120x2.5mm Galvanized Square Tube | ||

| Steel Roof Truss: | Top Chord: | 120x60x2.5mm Galvanized Square Tube | |

| Bottom Chord: | 80x80x2.0mm Galvanized Square Tube | ||

| Web Member: | 40x40x2.0mm Galvanized Square Tube | ||

| Steel Floor Truss: | Top Chord: | 80x40x2.0mm Galvanized Square Tube | |

| Bottom Chord: | 80x40x2.0mm Galvanized Square Tube | ||

| Web Member: | 40x40x2.0mm Galvanized Square Tube | ||

| Steel Purlins: | Wind Purlins: | 60x40x1.5mm Galvanized Square Tube | |

| Wall Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Roof Purlins: | 60x40x1.5mm Galvanized Square Tube | ||

| Floor Purlins: | 120x60x2.5mm Galvanized Square Tube | ||

| Bracing: | Ф12mm | ||

Prefabricated House Design

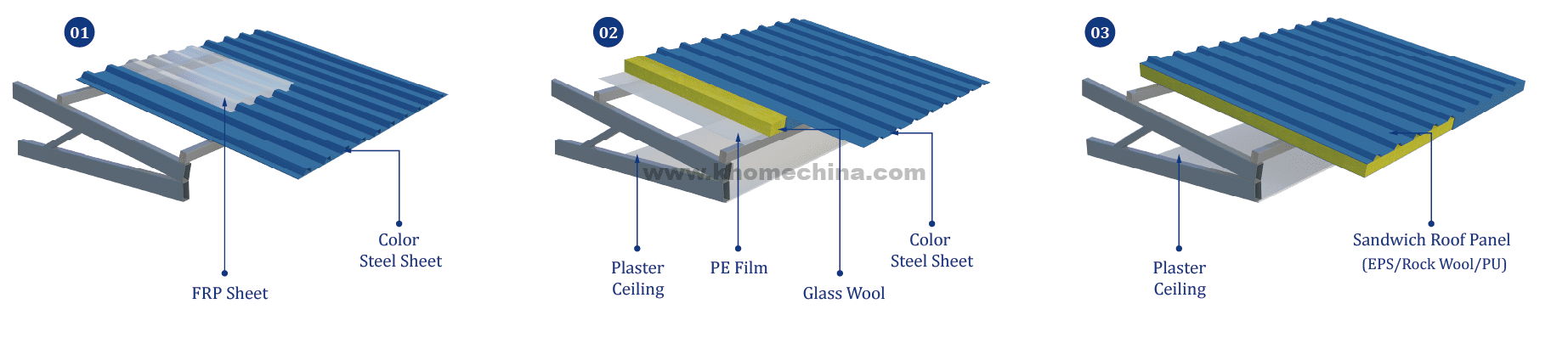

Prefabricated House Roof Options

The roofs of prefabricated houses can be designed and manufactured with various construction materials and technologies. Here are some common types of prefabricated house roofs:

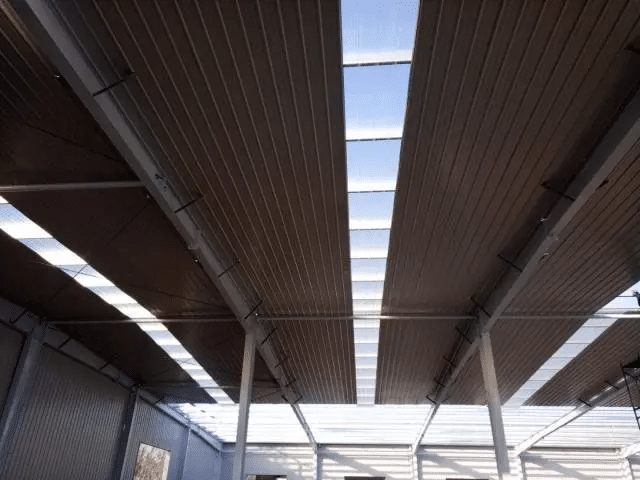

1) Color steel Roofing Sheet & FRP sheet

Color steel sheets, also known as colorful pressure tiles are color-coated steel plates, and they are bent coldly into various wave types. This material is light and durable, difficult to ignite, and anti-corrosion, while easy to install and maintain. Color steel sheets are widely used and are suitable for various types of buildings. It is mainly used in industrial factories, commercial buildings, civil housing, agricultural greenhouses, parking lots, stadiums, exhibition halls, and other construction fields.

FRP sheets are usually used for the top or walls of the building. They have high transparency and anti-ultraviolet ability and can provide sufficient natural light without using electric lights to save energy and environmental protection.

In architectural design, color steel sheet Roof and FRP sheet can be supplemented and cooperate with each other. For example, in the roof structure of the factory building, the FRP sheet can be used to cover the parts that can be permeated, such as channels, machines, or lanes to meet light transmission requirements and performance needs. At the same time, colored steel sheets can be used to cover other parts, such as walls and main roofs, and also play a role in heat insulation. This structural design not only meets the brightness and energy conservation needs of the building but also ensures the strength and stability of the building.

In short, the specific use of color steel sheet Roof and FRP sheet in architectural design can be adjusted and selected according to factors such as building use, climate environment, the characteristics of building materials, and building design needs.

2) ceiling + PE Flim + Glass wool + Color steel roofing sheet

The roof composed of glass cotton and colored steel plates can have a certain heat insulation and insulation effect. Glass shredded cotton is an insulating material. Its insulation performance can reduce the increase in the temperature in the summer house and the decrease in the temperature in the winter house to achieve the purpose of heat insulation. The color steel plate is lighter, suitable for roofs, and can effectively waterproof, wind resistant, corrosion resistant, fire prevention, etc. In actual use, you need to choose the appropriate thickness and material according to the local climate and environmental conditions and pay attention to strengthening the stability of the roof structure to ensure the safety and service life of the roof.

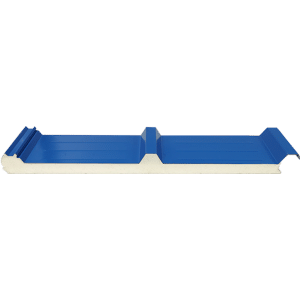

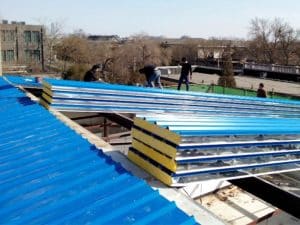

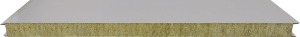

3) ceiling + Sandwich Roof Panel

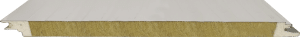

Sandwich roof panels are a type of roofing system that consists of two metal sheets that are bonded to a core material. The core material is usually made of insulation material such as polyurethane foam or rock wool. Sandwich roof panels have numerous benefits, including high thermal insulation, excellent fire resistance, and ease of installation.

Rock Wool Sandwich Roof Panel EPS Sandwich Roof Panel PU Sealed Rock Wool Sandwich Roof Panel PU Sandwich Roof Panel

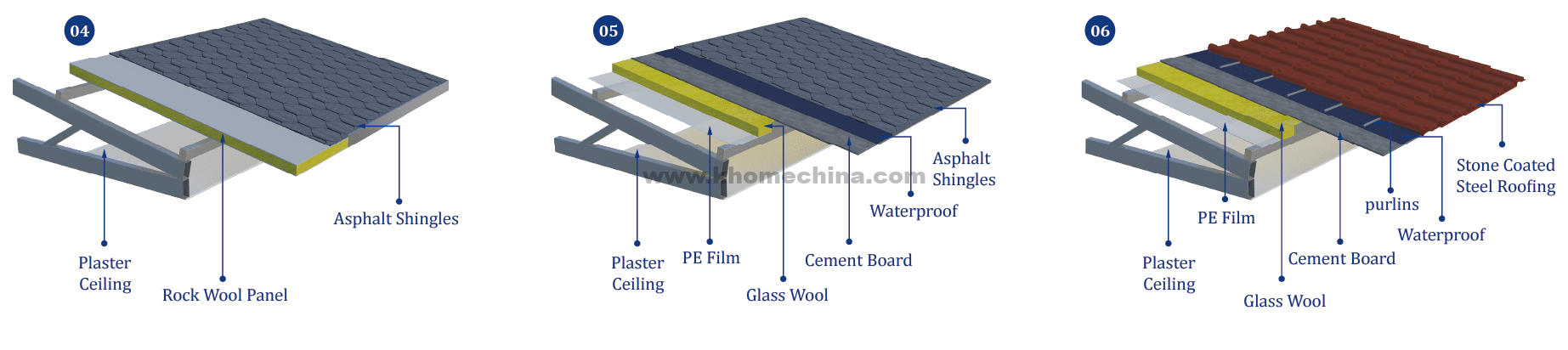

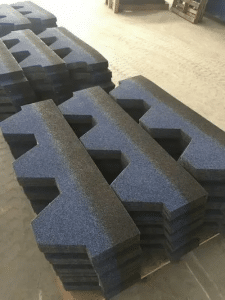

4) ceiling + Sandwich Panel + asphalt shingles

If you want a simple installation method and a beautiful appearance and a more economical price, this is a good option. Sandwich panels are a popular roofing material. They consist of two metal panels with insulation material sandwiched in between. Asphalt shingles, on the other hand, are a type of roofing material made of asphalt-impregnated paper and coated with mineral granules. An advantage of using sandwich panels in combination with asphalt shingles is that they can provide additional insulation and durability. They can help to extend the lifespan of your house.

Rock Wool Sandwich Panel EPS Sandwich Panel PU Sealed Rock Wool Sandwich Panel PU Sandwich Panel

5) Ceiling + PE Flim + Glass Wool + Cement Board + Asphalt Shingles

Glass wool is a commonly used insulation material with the characteristics of light weight, good thermal insulation effect, and excellent fire resistance. Compared with other insulating materials, the price of glass wool is relatively low, which is an insulating material with high-cost benefits. Asphalt shingles are popular because they are relatively inexpensive, easy to install, and come in a variety of colors and styles. They usually have the bottom of the adhesive layer, which makes it easier to install. They can last anywhere from 15 to 30 years, depending on the quality of the shingles and the climate they are in.

PE Flim Glass Wool Cement Board Asphalt Shingles

6) ceiling + PE Flim + Glass wool + purlins + Stone Coated Steel Roofing

Stone Coated Steel Roofing is becoming increasingly popular as a roofing material for residential homes. Its durability, weather resistance, and long lifespan make it a popular choice. The stone coating gives it an attractive appearance that can complement many different architectural styles. Stone Coated Steel Roofing is a great option for a house roof due to its durability, weather resistance, long lifespan, and attractive appearance. If you are considering a new roof for your home, Stone Coated Steel Roofing is definitely worth considering.

Prefabricated House Wall Options

In terms of sound insulation performance, lightweight walls may be better than concrete walls, depending on their design and construction. The concrete wall has high quality and density, which helps to block and absorb sounds. However, their rigidity also means that they can pass vibration and sound waves through walls, resulting in sound leakage. On the other hand, lightweight walls can be used with good sound absorption properties, and at the same time, they also provide greater flexibility and less vibration transmission. For example, a lightweight wall built with gypsum boards, insulation materials, and elastic channels can provide better sound insulation performance than concrete walls. The main difference between the concrete wall and the lightweight wall is the quality of the wall. The concrete wall is usually heavier and density, while the light wall is usually used with low density and weight.

For the sound insulation design of the lightweight wall, there are several advanced treatment methods: Use isolation band: Inside the wall, installing sound insulation bands can effectively isolate noise and reduce wall resonance. The isolation zone is usually made of rubber, polyurethane, glass fiber, and other materials. Using sound insulation board: sound insulation board is a standard sound insulation material, which is usually made of high-density materials. It has a good sound insulation effect and high density, which can absorb and isolate walls and indoor and outdoor noise. Common sound insulation boards include mineral cotton plates, glass fiber boards, calcium silicate plates, etc. Installing the double-wall structure: The double-wall structure is a very good design for sound insulation. It is composed of two walls. The sound insulation board is used on both sides. The sound insulation material is filled in the middle, which can effectively isolate the sound.

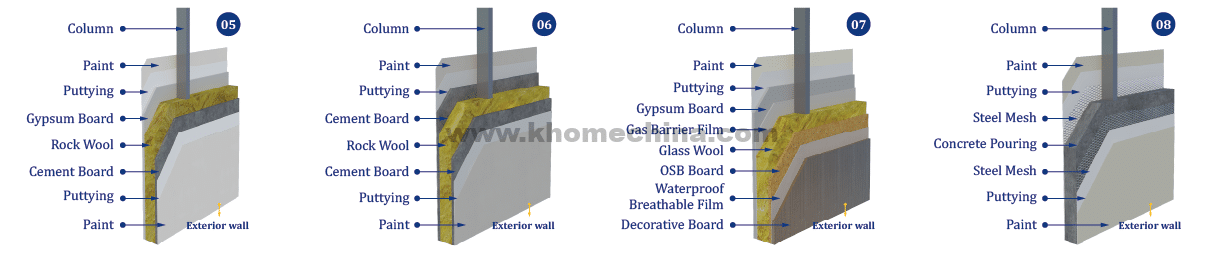

Here are some wall construction methods for your reference:

The first four methods only need to be fixed with screws, which is very simple and convenient. This will save your cost, including labor costs, material costs, and time costs. The latter four wall treatment methods need to be painted, but the house will be more beautiful. Of course, the price will be more expensive. Please contact us to get the quotation and your exclusive plan in the budget.

1) Color Steel Sheet

The simplest wall treatment. Because there is no insulation layer, it is not suitable to use as a living place. It is common in garages, agricultural sheds, simple warehouses, factories, and other industries or agricultural buildings.

2) Sandwich wall Panel

The use of the core plate as the wall material has the following advantages:

Inquiring about thermal insulation performance: The insulation and thermal insulation performance of the sandwich board are very superior. The insulation material filled in the middle can effectively isolate the indoor temperature difference, greatly reducing the coefficient of heat transfer, and improving the energy-saving effect of the building.

Construction is convenient and fast: the transportation and installation of the sandwich board are easier and easy to move, which can greatly shorten the construction period.

Environmental protection and energy saving: The insulation materials and substrates used by the sandwiches are mostly environmentally friendly materials. A large amount of garbage will be generated during the construction process to reduce environmental pollution. At the same time, due to the good thermal insulation effect during use, it greatly reduces energy consumption and achieves realization. Energy saving and environmental protection.

Lightweight and high strength: The thickness of the sandwich plate is thinner, and the weight is lighter than the traditional wall material, but the intensity is very high, which can meet the building’s requirements for the wall material.

Good decorative effect: The surface materials of the sandwich board can be treated according to personal preference, such as stuck stone materials, tiles, paint coatings, and other decorative methods, bringing good decorative effects.

3) Color Steel Sheet + Rock Wool + Color Steel Sheet

This is an alternative to the sandwich wall panel, which retains the advantages of the sandwich wall panel, but the price is more advantageous. But you need to consider the local labor cost. In fact, we recommend you use the sandwich wall.

4) Bamboo Fiberboard + Rock Wool + Color Steel Sheet

Beautiful: Bamboo fiberboard has a very good appearance, and there are many different colors and patterns to choose from.

Environmental protection and health: Bamboo fiberboard is made of environmentally friendly materials. The composition does not contain paint, has no odor, harmless to the human body, has no harmful gas such as formaldehyde, and achieves zero -carbon and zero emissions.

Waterproof and moisture-proof: good moisture-proof performance, suitable for humid areas, difficult to enter humidity, dry and comfortable indoors, no deformation, no water seepage or leakage, allowing you to completely get rid of the mildew of the wall.

Durable anticorrosive: High-strength Bamboo fiberboard, good toughness, light resistance and impact resistance, non -deformation, difficulty aging, resistance to creep, not easy to corrode, long service life.

5) Paint + Puttying + Gypsum Board + Rock Wool + Cement Board + Puttying + Paint

Gypsum board is based on plaster, adding fiber, adhesive, and modified agent, and is made of mixed and drying and drying. It has the characteristics of fire prevention, sound insulation, heat insulation, light quality, high strength, and small contraction rate because the gypsum board is relatively easy to scrape the putty, which is generally used to decorate the wall or top surface of the latex paint. However, poor water resistance should not be used in a humid environment, nor can it be used for the exterior wall of the building.

6) Paint + Puttying + Cement Board + Rock Wool + Cement Board + Puttying + Paint

Due to its many advantages, the cement board wall has been widely used in business, residential buildings, and other aspects.

Experiments have shown that the light wall of the cement board can keep dry without leaving traces, and there will be no dew water droplets in humid weather. The cement board partition wall is a professional waterproof board. Has a good waterproof moisture-proof performance.

In addition, it also has a sound insulation effect, which is much higher than the sound insulation effect of ordinary brick walls.

Completely dry work, assembly construction, and the wallboard can be cut arbitrarily to adjust the width and length. During the construction, the simple and hygienic transportation was greatly shortened, which greatly shortened the time limit, the material loss rate was low, and the construction waste was reduced.

The cement board partition wall can directly hang heavy objects with nails or upper expansion bolts. It can directly paste tiles, wallpaper, wooden skin, and other materials for finishing.

7) Paint + Puttying + Gypsum Board + Gas Barrier Flim + Rock Wool + OBS board + Waterproof + Breathable + Decorative Board

OBS Board Gypsum Board Decorative Board Decorative Board

8) Paint + Puttying + Steel Mesh + Concrete Pouring + Steel Mesh + Puttying + Paint

Frequently asked questions

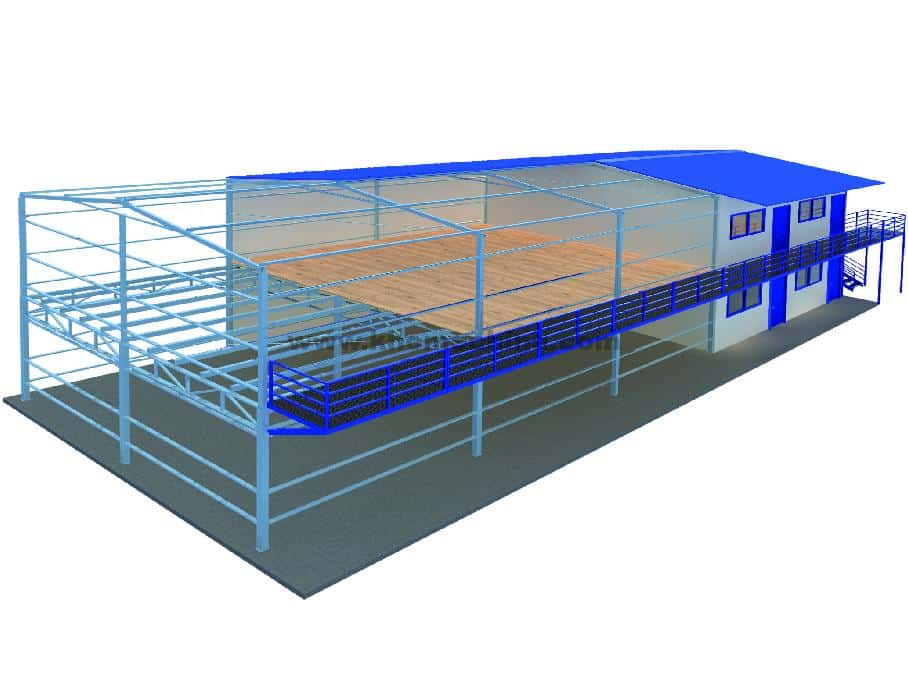

T-type Prefabricated house projects show

SEND A MESSAGE