steel structure workshop

Portal Steel Structure Workshop / steel structure workshop building / steel structure workshop Manufacturer

prefabricated steel structure workshop

Steel structure workshops are a common type of modern steel industrial buildings. They are designed and built for various industrial production activities. Steel frame workshops use steel as the main building material. Due to their durability, cost-effectiveness and customizable design options, they are widely used in various industrial fields such as machinery manufacturing, automobile manufacturing, electronic appliances, food processing, etc. At the same time, its flexible spatial layout and excellent structural performance can be built into warehouses, production workshops, purification workshops, machining workshops, etc. to meet the needs of different production lines.

The steel frame of the steel structure workshop building is manufactured with the use of superior quality raw materials and cutting-edge techniques and formed by main steel frames, which are linked up by Z-Shape, H-Shape, and U-Shape steel components. Roof and walls can be chosen from a variety of wall panels or any components that you prefer, such as brick, cement panel, sandwich panel, etc. The quality and design are customized based on your actual needs, and then we find the most cost-effective steel structure building solution for you. All the items are pre-produced in our factory and the dimension of the frame are calculated by computer precision, and the installation effect can be accurately controlled within millimeters.

| Main structure | H-section steel | Q345/Q235 steel H beam, Box column is also available |

| Welding | Automatic Submerged Arc Welding | |

| Rust removing | Shot blasting | |

| surface processing | twice primer and twice finish Alkyd Paint or hot dip galvanized | |

| High strength bolt | Grade 10.9 | |

| Substructure | Angle brace | L50x4, Steel Q235, Process, and painting |

| Cross bracing | Dia.20 round bar, Steel Q235, process and pre-galvanized | |

| Tie bar | Dia.89*3 round pipe, Steel Q235 Process, and painting or pre-galvanized | |

| Batter brace | Dia.12 round bar, Steel Q235 process and pre-galvanized | |

| Ordinary bolt | Galvanized bolt | |

| Roof | Purlin | C channel or Z channel, steel Q235, galvanized |

| Roof panel | (50mm, 75mm, 100mm, 150mm) Sandwich panel or corrugated GI color steel sheet | |

| Transparent skylight | 1.2mm FRP/customized | |

| Accessories | Sealant, self-tapping screw, etc. | |

| Edge cover | Made of color steel sheet | |

| Gutter | Made of steel sheet thickness 0.8mm, or PVC | |

| Rainspout | PVC pipe | |

| Wall | Purlin | C channel or Z channel, steel Q235, galvanized |

| Wall panel | (50mm, 75mm, 100mm, 150mm) Sandwich panel or (0.4mm, 0.5mm, 0.6mm, 0.7mm) corrugated GI color steel sheet | |

| Accessories | Sealant, self-tapping screw, etc | |

| Edge cover | Made of GI color steel | |

| Ventilator | unpowered axial-flow ventilator or monitor roof | |

| Door & window | Electric rolling door/sliding door, PVC/Alu. alloy window | |

| Crane | With or without a crane, ranging from 5 tons to 20 tons |

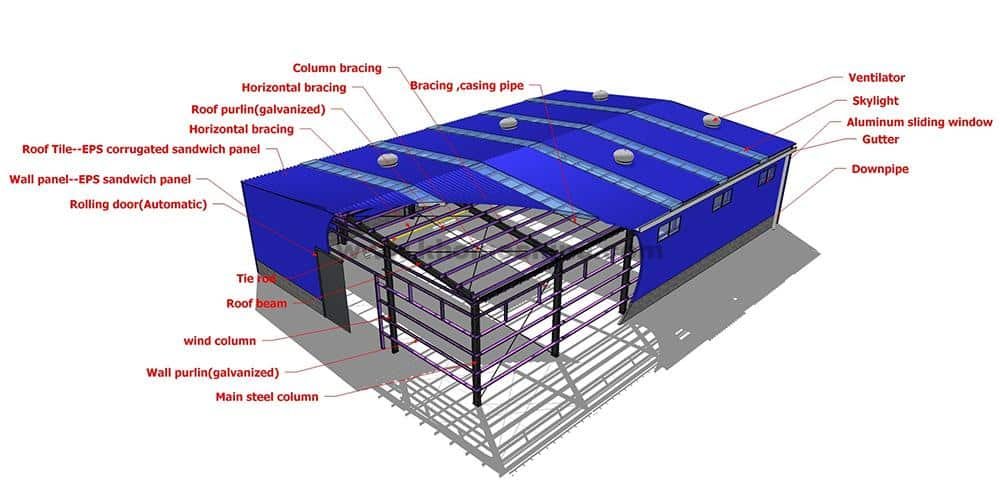

Main parts of steel structure workshop construction

- Embedded parts, (to stabilize the structure of the plant)

- Columns generally use H-shaped steel or C-shaped steel (usually angle steel used to connect two C-shaped steel)

- For beams, generally C-shaped steel and H-shaped steel are used (the height of the middle product is determined according to the span of the beam)

- Purlin: C-shaped steel and Z-shaped steel are generally used.

- Supports and braces are usually round steel.

- There are two types of tiles, the first is a color steel tile. The second type is composite sandwich board. (Polyurethane or rock wool is sandwiched between the two-layer color-coated board, which plays the role of warming in winter and cooling in summer, and also has the effect of sound insulation and fire prevention).

type of steel workshop frame

There are many types of steel structure frames, such as portal steel frames, frame steel frames, and grid steel frames. K-HOME mainly provides portal steel structure frame types. According to the structural form, these frames can be divided into single-span, double-span, multi-span, and with eaves, with adjoining roofs, and other forms.

Single-Span Steel Structure Workshop

The single-span steel structure workshop adopts a clear span design. A large open space can be achieved without internal columns or supports in the middle of the entire plant. This design provides flexibility for indoor layout. The clear span width is generally 6-24 meters, and more than 30 meters is a large-span steel structure. Single-span workshops are generally used for production lines, warehouses, and large manufacturing processes.

- Single-Span Steel Structure Workshop

- Single-Span Steel Structure Workshop

Multi-Span Steel Structure Workshop

A multi-span steel structure workshop refers to a building with multiple spans or sections, each of which is supported by columns or walls. This design ensures the integrity and stability of the structure while allowing flexible changes in roof height and layout within the workshop. Multi-bay factories are suitable for complex manufacturing processes, assembly lines, and facilities that require space to be divided into different operating areas.

- Multi-Span Steel Structure Workshop

- Multi-Span Steel Structure Workshop

According to whether there is a crane, it can be divided into portal steel structure and portal steel structure with overhead crane. At K-Home, we focus on the design and manufacture of steel structure buildings equipped with bridge crane systems. We can provide customized combined solution of overhead crane and steel structure workshop according to your needs. With a professional team of engineers, sales teams, and after-sales service teams, we are always ready to help your project go smoothly.

Five Points Should Be Paid Attention To In The Design of Steel Structure Workshop:

1. Thermal Insulation and Fire Prevention of Steel

Steel has high thermal conductivity, and its thermal conductivity is 50w (m.℃), so when the ambient temperature of the steel structure reaches above 150℃, it must be designed for heat insulation and fire protection.

2. Roof Support System and Roof Design

The layout of the roof support system should be determined according to the plant span, height, column network layout, roof structure form, crane tonnage, and seismic fortification intensity of the area. Regardless of whether there is a purlin system or a roof without a purlin system, the upper string lateral support shall be provided on the roof truss upper string and the skylight frame upper string. For workshops with roof truss spacing not less than 12m, where there are super-heavy bridge cranes in the workshops, or where there is large vibration equipment in the workshops, longitudinal horizontal supports should be installed.

At present, there are two commonly used steel structure roofing methods on the market: ① Rigid roof: double-layer color profiled steel plate with insulation cotton; ② Composite flexible roof: composed of roof color steel plate inner panel, gas barrier layer, insulation layer, coil Material waterproof layer.

3. Setting of Temperature Expansion Joint

The temperature change will cause the deformation of the steel structure factory building, which will cause the structure to produce temperature stress. When the plane scale of the factory building is large, in order to avoid large temperature stress, temperature expansion joints should be set in the vertical and horizontal directions of the factory building. The length of the section can be According to the steel structure specification.

4. Anti-rust Treatment

The surface of the factory steel structure will corrode when exposed directly to the atmosphere. Corresponding countermeasures and measures should be taken in general layout, process layout, material selection, etc. according to the corrosive medium and environmental conditions of the plant to ensure the safety of the plant structure. Generally, anti-corrosion primers and topcoats are often used for the anticorrosion of steel structures, and the number and thickness of coating layers are often determined according to their use environment and coating properties.

5. Facade Design

The facade of the steel structure factory building is mainly determined by the process layout. Under the requirements of the process, the facade is concise and magnificent, while the nodes are as simple and unified as possible. Jumping colors and cool colors are often used in the design of light steel factory buildings, focusing on the main entrances and exits, outer gutters, and side flooding, which not only reflects the magnificence of modern factories but also enriches the facade effect.

In short, the design of steel structure factory buildings should be designed according to their characteristics. The building structure should be designed according to its characteristics so that the design is safe, reliable, economical, reasonable, and beautiful.

How Does a Steel Structure Work?

There are five main types of structural members that make up a steel frame – tension members, compression members, bending members, composite members and their connections.

The steel components are assembled into frames on site. The processes involve lifting and placing the components and then joining them together. Usually this is done by bolting, but sometimes on-site welding is used.

Anchor bolt retest → steel component unloading → component entry inspection → car crane directly hoisted in place → anchor bolts are temporarily tightened → cable wind rope is temporarily tightened and stabilized → steel column axis position and verticality adjustment → steel column bolts and Column foot pressing plate tightening and welding → next steel column installation → steel tie rod installation → forming the first stable lattice system → steel roof truss ground assembled into a whole and two machines lifted in place to form the first steel roof truss → Symmetrical installation of columns and roof truss system on both sides, and so on. Installation is completed and the structure is checked and accepted.

Factors affecting the cost of steel structure:

- According to actual needs, every 10 cm increase in building height will increase the cost by 2% to 3%.

- Without crane tonnage, the choice of crane tonnage is also a big research topic. If the selected tonnage is too large, it will cause equipment waste, and it will not meet the construction needs if it is too small. Of course, the price is different.

- Building envelope structure, which is also a cost consideration, such as doors and windows, exterior walls, etc.

- Relevant factors such as the design structure type, construction time and purpose of the local factory.

- The size of the building area is very necessary. A large amount of steel is needed, and the cost of the steel plant is relatively high. The width determines its size, which of course is closely related to the design structure of the workshop.

- The span of the steel structure. Generally speaking, the larger the span, the lower the cost. Of course, the span is arranged according to one’s own needs, the same is true for spans of different designs, and the requirements for column spacing are also very different.

- The steel consumption and cost of the steel structure factory & workshop have a great influence on the steel consumption. In the same material, the area has a great influence on the number of steel bars, and the size of the building area determines the number of steel bars.

- The design directly determines the amount of materials used and the cost of the quotation. Therefore, the design of construction drawings and schemes must be rationalized. The main design influence is the design of basic design, steel beam design, column network design and other aspects. Designers It is necessary to consider relevant factors to rationalize the design and quotation of the entire structure.

K-HOME Steel Structure workshop Building Projects

We have delivered many high-quality projects to customers around the world (including Southeast Asia, the Middle East, Africa, etc.). These projects are designed to meet different needs. They are standardized prefabricated steel structure workshops or customized prefabricated steel structure buildings with special process requirements. At K-HOME, our professional team can provide you with cost-effective and fast delivery services.

Portal Steel Structure Workshop in China

This is a standard workshop building we designed for a Chinese customer. There are 10 buildings in total, meeting the needs of different production lines. The project adopts a brick-concrete structure. The enclosure system uses metal cladding panels. Generally speaking, if there is no special requirement, it is cost-effective to use metal cladding panels as a maintenance system. At the same time, they are lightweight and easy to install.

steel structure fabrication workshop in the Bahamas

This project was designed and built for our Panama client. The project is 46m x 30m x 8.25m in size and is used as a supermarket. It uses a two-story structure. In order to meet the special use requirements of the building, the enclosure structure is built with polyurethane sandwich panels.

metal workshop building in congo

This is a production workshop we designed for a customer in the Democratic Republic of Congo. The workshop is 40x170x17m in size and is used to produce steel bars. The workshop must be adapted to the requirements of the equipment, so the roof is designed as an asymmetrical pitched roof.

Steel Structure Workshop Advantages

Professional steel structure building solution manufacturer | k-hOME

As a leading steel structure workshop manufacturer, K-HOME has complete qualifications and rich project experience, and is committed to providing customers with one-stop services from design to construction.

We know that a high-quality steel workshop building requires strong and durable materials, precise design, and efficient construction.

Therefore, we strictly control every process—from engineering calculations and detailed design to production and manufacturing, and then transportation and installation—to ensure that your project is delivered on time and with high quality.

Our steel structure buildings are all built with high-quality steel. After strict certification by the SGS testing agency, it ensures that they meet the building standards and meet the earthquake, wind and fire protection requirements of different regions. Whether it is a large industrial workshop, a logistics warehouse, or a special building (such as a low-temperature cold storage, a multi-span steel workshop, or a crane steel structure building), we can provide customized solutions according to your specific needs.

With many successful cases and 20 years of industry experience, we have delivered many high-quality projects to customers around the world (including Southeast Asia, the Middle East, Africa, and other places). Whether you need a standardized prefabricated steel structure workshop or a custom prefabricated steel building with special process requirements, K-HOME can provide you with cost-effective and fast delivery services with its professional team and mature supply chain.

Just tell us your needs and we will immediately match you with the best solution!

Frequently Asked Questions

Related Product

Related Articles

SEND A MESSAGE