steel structure warehouse

warehouse steel structure / prefabricated steel structure warehouse / steel structure warehouse building / china steel structure warehouse

Warehouses are important places to store materials, and their performance directly affects operational efficiency.

Traditional warehouses have obvious limitations in terms of space utilization, construction cycle, and structural stability. In contrast, steel structure warehouses have become more efficient storage solutions due to their high strength, durability, and fast construction.

Whether in manufacturing, logistics, or agriculture, steel structure warehouses can provide flexible, durable, and low-maintenance solutions.

China Steel Structure Warehouse & Steel Structure Workshop supplier

Need to build a large warehouse quickly and at a low cost? K-HOME steel structure warehouse is the best solution to meet your inventory storage and management needs. Compared with traditional concrete buildings, steel structure buildings use steel plates or section steel instead of reinforced concrete, which has higher strength, better earthquake resistance, and lower cost. And because the components can be manufactured in factories and installed on-site, the construction period is greatly reduced. Because steel can be reused, construction waste can be greatly reduced, and it is more environmentally friendly, so it is widely used all over the world and used in industrial buildings, commercial buildings, and civil buildings.

The operation of each steel structure warehouse requires different functions. We provide customized architectural designs for prefab warehouses of various lengths, widths, and heights. We have an experienced architectural design team that can help you realize all custom components.

What is a Steel Structure Warehouse building?

A steel structure warehouse is an industrialized building constructed by industrialized prefabrication and modular assembly with steel as the main load-bearing structure. Its core structure adopts high-strength steel beams, steel columns and other components, with color steel plates, sandwich panels and other enclosure materials to form a complete building system.

Steel structure warehouse building has the following significant features:

1、With standardized design, all steel components are prefabricated in the factory, and only bolt connection is required on site, so the construction speed is relatively fast.

2、Steel has high strength, good elasticity and plasticity, and can withstand larger loads and pressure. Moreover, this kind of building can realize a large span of 30-60 meters without column space, which greatly improves the utilization rate of storage.

3、 The density of steel is relatively low, and compared with materials such as concrete, it has a lighter weight, which can reduce the bearing pressure of the foundation and foundation.

4、Steel structure components can be reused, reducing the generation of construction waste. Meanwhile, the energy consumption during construction is less, which meets the requirements of green building.

5、After the steel is processed, it has better fireproof and anticorrosion performance, which can prolong the service life of the building.

From the perspective of application scenarios, steel structure warehouses are widely used in logistics centers, industrial workshops, warehouses, etc. Its flexible design can also meet future expansion needs by increasing the number of spans or extending the length at the end to achieve flexible expansion of storage capacity.

- steel structure warehouse building

- warehouse structure

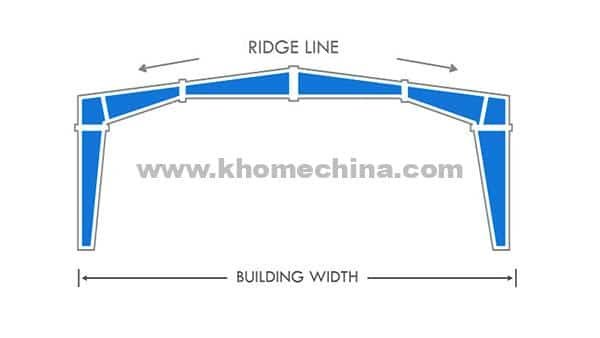

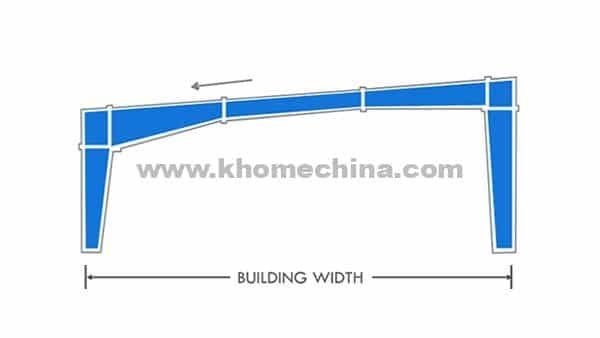

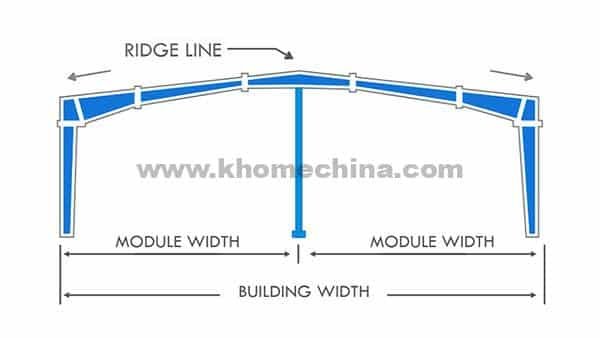

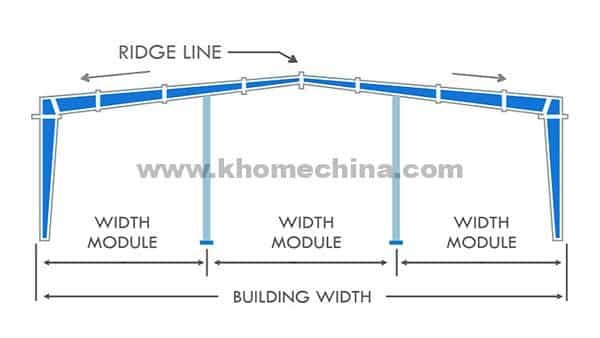

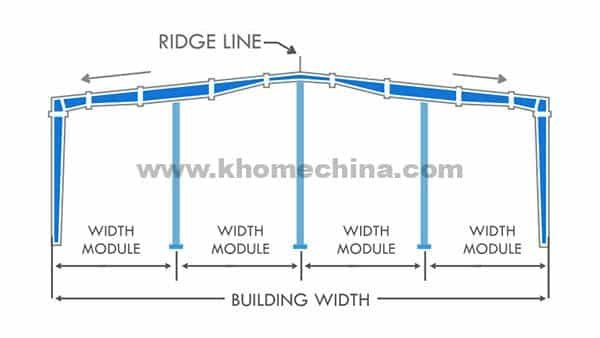

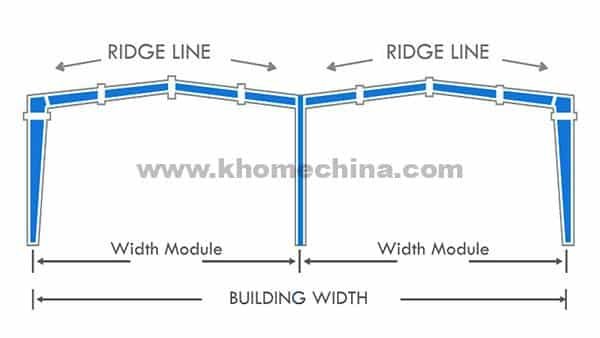

Common types of portal steel frames in prefabricated warehouses

Portal steel frame structure is a traditional structural system. This type of structure is a single-story structure. The column spacing is free and flexible, which can meet the construction and utilization requirements under different climatic conditions. They are usually used in warehouses, workshops and other places that require low cost and large open space.

Portal steel frame structure can be designed as single-span, double-span, multi-span and other forms according to actual needs. How to choose the right frame structure? You need to consider the building width, height and local dynamic load factors such as wind load and snow load. You can contact us, our professional team can calculate and recommend the most suitable type of portal steel frame for you. If your building needs to be equipped with a crane, we also offer integrated crane building solutions adapted to cranes.

Core Components of the Prefabricated Warehouse Building

The structural integrity and durability of prefabricated warehouse buildings depend on the ratio of a series of high-performance materials and engineering elements:

- Steel columns: Made of Q355B welded H-shaped steel to ensure excellent load-bearing capacity and toughness.

- Main beams and platform beams: Made of Q355B welded H-shaped steel to provide necessary support for the roof system and mezzanine.

- Roof and wall supports: Made of Q235B round steel components to enhance lateral stability and wind resistance.

- Tie rods: Made of Q235B welded tubes to enhance the overall rigidity of the structure.

- Purlins and wall beams: Lightweight and strong, made of thin-walled Z-shaped and C-shaped Q235B steel, respectively.

- Tie rods: Additional Q235B round steel components to reinforce portal frame components.

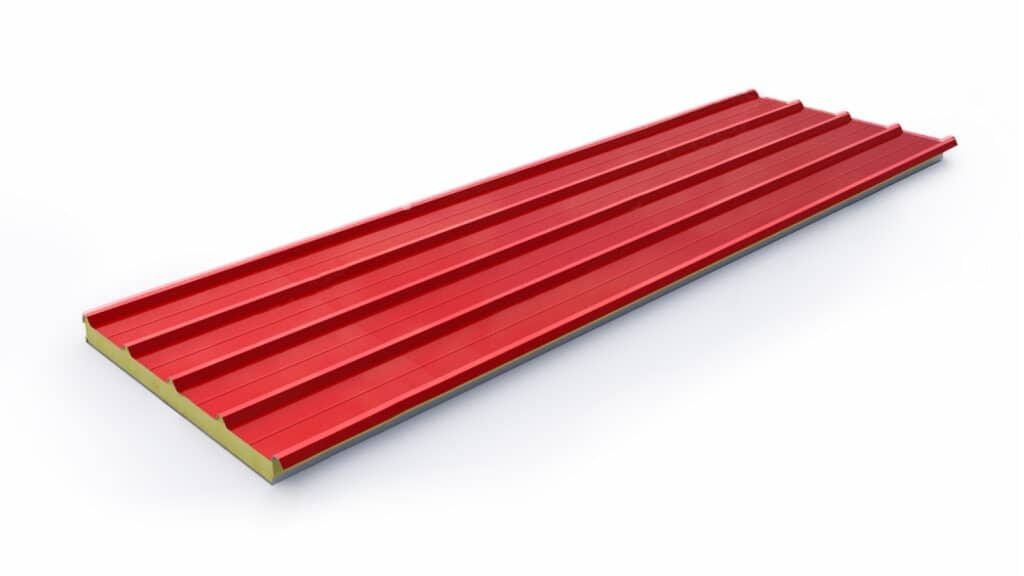

- Wall panels: Usually made of 0.5 mm corrugated color steel sheets, with excellent weather resistance and durability. Sandwich panels can be selected if there are specific environmental requirements.

- Roof panels: There are many construction methods. Usually 0.5mm thick color steel corrugated board is used, which is cost-effective. There are two other ways, one is to use glass wool + color steel corrugated sheet, and the other is to use sandwich roof panel.

Angle Channel-C H-Beam I-Beam metal cladding panel sandwich roof panel

Steel structure warehouse specification:

| Structures | Part | Specification |

|---|---|---|

| Main Steel Frame | Frame column and beam | Q355 |

| End-wall column | Q355 | |

| process 1 | Welding | Automatic submerged arc welding |

| process 2 | Rust removal | Sandblasting |

| process 3 | Surface finish | Alkyd paint or galvanized |

| process 4 | Intensive bolt | M20-M30, Grade 10.9S |

| Supporting Sys | Angle bracing | Angle iron L50x4 |

| Roof bracing | Φ20, Round Steel | |

| X bracing between columns | Φ20, Round Steel | |

| Tie rod | Φ10, Round Steel | |

| Roof bar | 32 mm diameter Steel Pipe | |

| Purlin | C/Z100-250, Q235, galvanized | |

| Roof Sys | Roofing material | 0.5mm steel plate, Service life 20 years |

| Skylight panel | 1.5mm V840/V760 | |

| Gutter | Galvanized sheet or Stainless steel | |

| PVC downspout | 160 | |

| Wall Sys | Wall material | 0.5mm steel plate, Service life 20 years |

| Door | Electric rolling Door | |

| Window | Aluminum alloy or plastic steel window | |

| Others | Crown 3-50T | Can be customized |

| Steel platform | Can be customized | |

| Parapet (wall) | Can be customized |

Advantages of prefabricated steel structure warehouses

- Because the steel structure column area is small and the indoor space area occupied is small, compared with the space area occupied by the traditional reinforced concrete structure column, the indoor space separation is somewhat hindered, and the use of steel structure to build a warehouse is the most ideal solution.

- The steel structure is not only lightweight, high strength, good plasticity, and toughness, so steel components can be processed to produce different shapes of components. The quality and shape of the structure meet the requirements of customers. The construction week of the steel structure is short, which can reduce the investment cost accordingly. The steel components can be processed in the factory, which can reduce the steps of on-site construction and production. The steel components processed in the factory have high strength and meet the standards of building construction.

- The material of the steel structure building is environmentally friendly, and the installation is simple and convenient. The building structure that does not need to be re-used can also be rebuilt by demolishing. Moreover, construction and demolition have little impact on the surrounding environment and will not have much impact on the surrounding environment. The materials can be Recycled and reused, reduce the waste of materials and save resources. Steel components have their own advantages, and they can have different properties when used in buildings in various industries.

The Design of Steel Warehouse Buildings

Steel warehouse building design is crucial in the whole project. A variety of factors should be fully considered when designing the steel structure warehouse:

1、Clarify the use requirements and functional requirements of the warehouse. According to the required storage capacity of the warehouse and the characteristics of the goods, determine the overall scale and layout of the warehouse. At the same time, it is also necessary to consider factors such as cargo access, warehouse management, safety and protection, and make reasonable arrangements and planning in the design.

2、Choose a suitable warehouse structure to ensure the load-bearing capacity and stability of the warehouse. In the columns, beams, purlins and other structural components of the selection and design, should be based on the use of warehouse requirements and load characteristics of a reasonable choice. Ensure the strength and stability of the structure. At the same time, in the design process, external forces such as earthquakes, snow loads, and wind loads must also be considered, and corresponding design measures must be taken to ensure the safety of the warehouse.

3、Choose high-quality materials. In the choice of building materials, should be selected with good performance, reliable quality steel. Steel has high strength, corrosion resistance, construction convenience and other characteristics, can effectively enhance the service life of the warehouse and the overall quality. In addition, attention should be paid to fire prevention and anti-corrosion treatment to ensure the safety of steel structure warehouses during use.

4、Make detailed design drawings. Design drawings include two categories: structural drawings and construction drawings. The structural drawings mainly show the overall framework of the steel structure warehouse building. It lists in detail the size of each structural component, material, connection details, layout of each component and other detailed information about the structure. The construction drawings provide clear construction guidelines for the builder. They describe how these structural steel components will be assembled and connected, covering every detail from the foundation to the roof installation. The accuracy of the shop drawings has a direct impact on the progress and quality of the project and ensures that all phases of the project run smoothly.

Case Study – Tanzania Steel Structure Warehouse Building Design

We designed and built an 8,000 square meter steel structure warehouse building for a Tanzanian customer. The warehouse is 100m x 80m x 10 m. It adopts a multi-span and multi-double slope roof structure, and its stable structure adapts to local climatic conditions. At the request of the customer, brand elements were integrated into the appearance of the building. We use 3D renderings to allow customers to intuitively feel the built effect. The final delivered building not only meets the practical functional requirements, but also perfectly reflects the customer’s brand image and is highly praised by the customer.

The following pictures are the steel structure warehouse design drawings we designed for customers, you can refer to them for more information. If you plan to build a steel structure warehouse, you can communicate with us directly and we will provide you with customized design services.

K-HOME Steel Structure Warehouse Building Projects

Temporary Warehouse Building In the Philippines

This project is located in the Philippines. It is a prefabricated steel structure building of about 500 square meters, which serves as a temporary storage area. The steel structure adopts a portal steel frame with a single slope and single span design. The customer requires only a roof, no walls, to facilitate the entry and exit and storage of goods. The customer will install solar panels on the roof later, which places high demands on the load-bearing capacity of the roof. At the same time, downpipes and gutters need to be set up to ensure the smooth discharge of rainwater.

Below are the project pictures shared by the customer:

steel structure warehouse building in Mozambique

- Project name: Mozambique Steel Warehouse for Mining

- Client: A leading local construction contractor in Mozambique with over 25 years of experience in the industry.

- Core Needs: The client needs a reliable mine warehouse solution for their end-users. As this is their first time sourcing from China, the client has extremely high requirements for certainty regarding price, quality, and end-to-end service.

View this case study on steel warehouses. Learn how K-HOME tackles challenges.

Pre-Fabricated Warehouse in St. Vincent

This is a steel structure building project in St. Vincent. It is used as a production workshop. The size is 60m x 80m x 14m. It adopts portal steel frame and single slope roof design. The following is the installation effect shared by the customer:

Frequently asked questions

SEND A MESSAGE