Portal Steel Structure Building

K-HOME is your one-stop shop for customizing portal steel structure building.

Portal Steel Structure Building

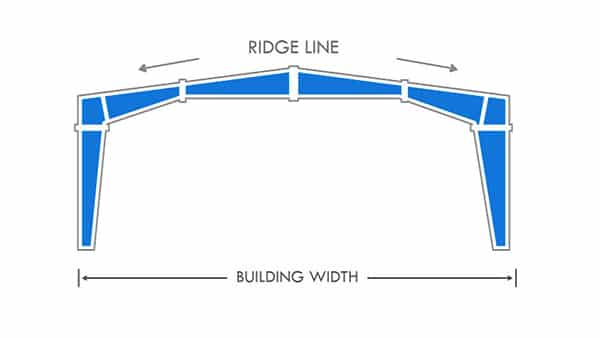

Steel structure buildings have many construction forms. The portal steel structure building is the most widely used. The Portal Steel Structure Building is a single-layer steel structure with a rigid connection. There is a common industry standard structural frame. A steel portal frame building consists of two columns and two inclined horizontal rafters. The two columns and rafters intersect to form a ridge, creating a rigid and stable double-sloping frame. Portal frames form the gable ends of a building. These frames are arranged in parallel repeats, forming the length of the building in a set number of bays.

It has the characteristics of simple structure, light self-weight, reasonable force, simple construction, short construction cycle, etc., and facilitates standardized processing in factories. Due to its multifunctional, intensity, and cost efficiency, the steel portal frame structure of this type is widely used in industry, business, sports facilities, and agricultural buildings.

Specifications of Portal Steel Structure Buildings

| Component Structure | Material | Technical Parameters |

|---|---|---|

| Main Steel Structure | GJ / Q355B Steel | H-beam, Customized height according to building requirements |

| Secondary Steel Structure | Q235B; Paint or Hot Dip Gavalnized | H-beam, Spans range from 10 to 50 meters, depending on design |

| Roof System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to design |

| Wall System | Color Steel Type Roof Sheet / Sandwich Panel | Sandwich panel thickness: 50-150mm Customized size according to wall area |

| Window & Door | Color steel sliding door / electric rolling door Sliding Window | Door and window sizes are customized according to design |

| Fireproof Layer | Fire retardant coatings | Coating thickness (1-3mm) depends on the fire rating requirements |

| Drainage System | Color Steel &PVC | Downspout: Φ110 PVC Pipe Water Gutter: Color Steel 250x160x0.6mm |

| Installation Bolt | Q235B Anchor Bolt | M30x1200 / M24x900 |

| Installation Bolt | High-Strength Bolt | 10.9M20*75 |

| Installation Bolt | Common Bolt | 4.8M20x55 / 4.8M12x35 |

Structural schemes for portal steel frame buildings

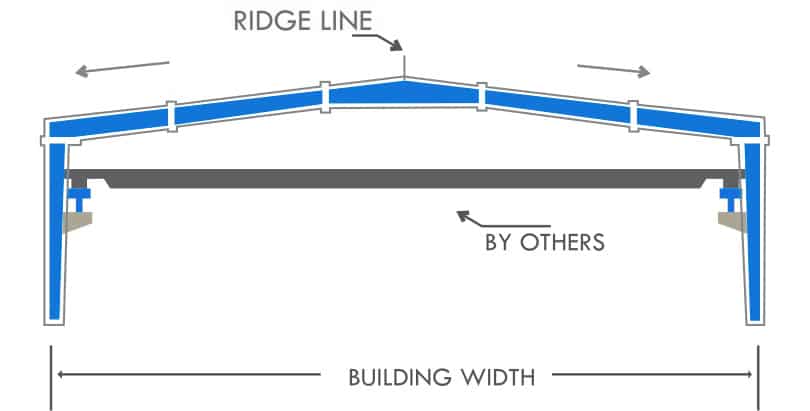

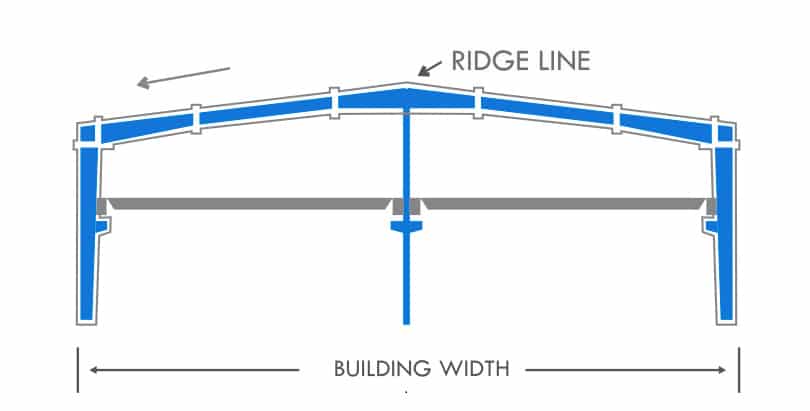

The load-bearing structure of a portal frame consists of two parts: the frame and the foundation. In this structure, the frame, purlins, and profiled steel sheets rely on each other through reliable connections and supports, making the stress distribution of the system more spatial.

Different types of portal steel structure buildings

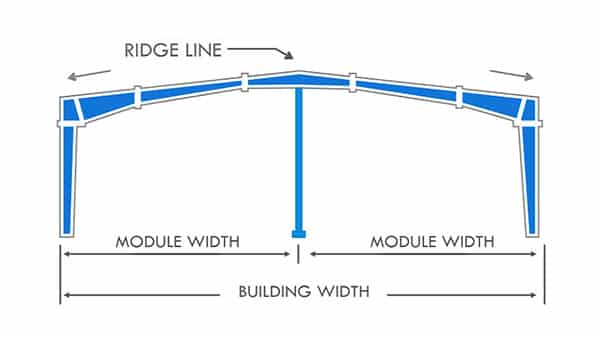

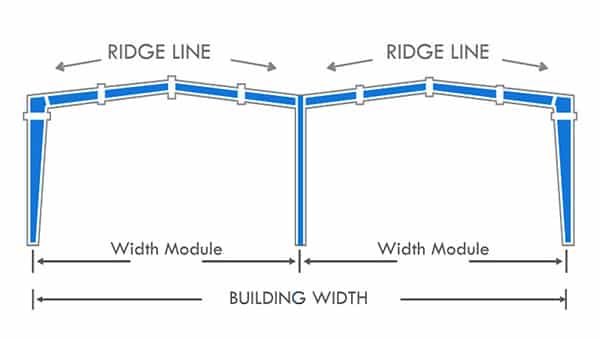

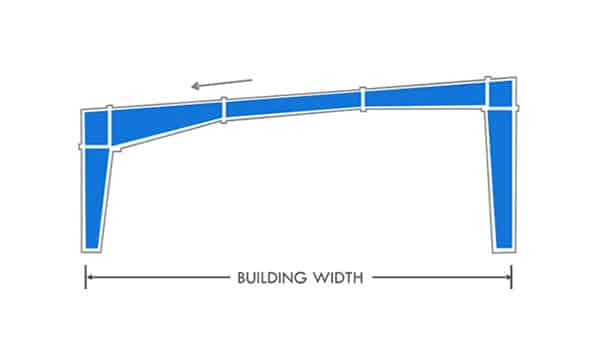

Portal frame structures are divided into two types: clear-span structures without internal columns and multi-span continuous structures with internal columns. The clear span can reach 48 meters. The internal single span of multi-span structures can reach 30 meters. In practical applications, depending on the project requirements, various forms such as single-slope, double-slope, multi-slope, and unequal span foundations can be adopted. Additionally, cranes can be integrated.

portal steel structure building size

The length and width of the portal steel structure building

Generally speaking, when laying the portal steel structure building, it should follow the principle of “length greater than the width”, which can reduce the amount of steel for the portal frame. At the same time can also reduce the wind load between the column support, thereby reducing the steel of the support system. For example, the size of the portal frame building is 60x50m, when the plant is arranged, 60m should be used as the length direction and 50m as the span direction.

Determine the reasonable span for the portal steel structure building

Span is the distance between two columns. The larger the span, the more open the interior space. We will determine economic and reasonable spans based on the height of the house, and satisfying production technology and use functions. In general, when the height and the load are certain, if the span is increased, the amount of steel for the portal frame will not increase significantly. But it saves space, reduces the basic cost, and makes the comprehensive benefits more considerable. It is found by a large number of calculations that when the span exceeds 48m, it is suitable for using multiple spans. Its steel volume saves more than 40% compared to a single-span portal frame. Therefore, when designing the portal steel structure building, a more economical span should be selected according to specific requirements. K-HOME will provide more options for you.

Column distance selection For portal steel structure building

The technology economy compares that the most economical portal steel structure building column spacing under standard load is 8-9m. When it exceeds 9m, the amount of steel in the roof bars and the wall frame system increases too much, and the comprehensive cost is not economical. The standard load here refers to: the roof is 0.3kn/㎡, and the basic wind pressure is 0.5kn/㎡. When the load is greater, the economic column distance should be reduced accordingly. For factories with more than 10 tons, the economic column distance should be 6-7m. K-HOME will perform scientific calculations based on the location of your project to ensure the security and firmness of the portal steel structure building.

Load Requirements

Steel structure buildings need to be constructed according to the local environment and usage requirements. Therefore, it is necessary to understand the load conditions of the geographical location. Generally, it’s important to understand what different loads represent: Dead Load(Building self-weight), Live Load (Personnel, goods, and equipment), Wind Load (Crucial in typhoon-prone areas), Snow Load (A key factor in northern winter warehouses), Crane Load(Essential in manufacturing workshops).

portal steel structure building Roof Options

The roofs of prefabricated houses can be designed and manufactured with various construction materials and technologies. Here are some common types of prefabricated house roofs:

1) Color steel Roofing Sheet & FRP sheet

Color steel sheets, also known as colorful pressure tiles are color-coated steel plates, and they are bent coldly into various wave types. This material is light and durable, difficult to ignite, and anti-corrosion, while easy to install and maintain. Color steel sheets are widely used and are suitable for various types of buildings. It is mainly used in industrial factories, commercial buildings, civil housing, agricultural greenhouses, parking lots, stadiums, exhibition halls, and other construction fields.

FRP sheets are usually used for the top or walls of the building. They have high transparency and anti-ultraviolet ability and can provide sufficient natural light without using electric lights to save energy and environmental protection.

In architectural design, color steel sheet Roof and FRP sheet can be supplemented and cooperate with each other. For example, in the roof structure of the factory building, the FRP sheet can be used to cover the parts that can be permeated, such as channels, machines, or lanes to meet light transmission requirements and performance needs. At the same time, colored steel sheets can be used to cover other parts, such as walls and main roofs, and also play a role in heat insulation. This structural design not only meets the brightness and energy conservation needs of the building but also ensures the strength and stability of the building.

In short, the specific use of color steel sheet Roof and FRP sheet in architectural design can be adjusted and selected according to factors such as building use, climate environment, the characteristics of building materials, and building design needs.

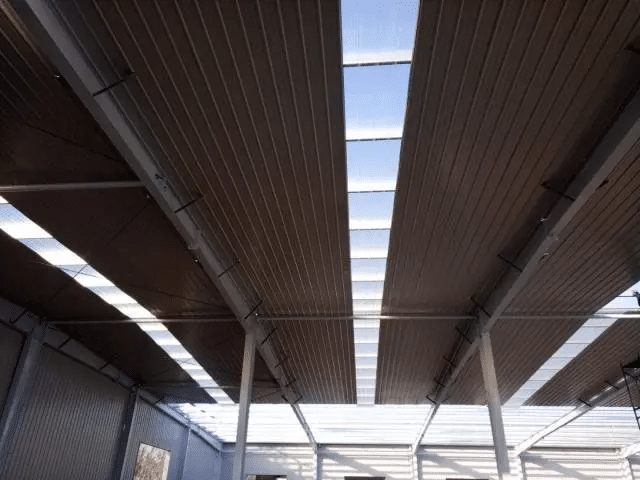

2) ceiling + Sandwich Roof Panel

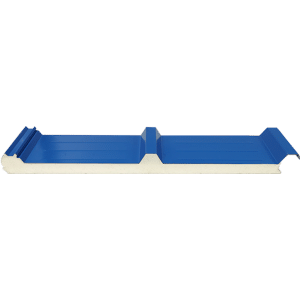

Sandwich roof panels are a type of roofing system that consists of two metal sheets that are bonded to a core material. The core material is usually made of insulation material such as polyurethane foam or rock wool. Sandwich roof panels have numerous benefits, including high thermal insulation, excellent fire resistance, and ease of installation.

Rock Wool Sandwich Roof Panel EPS Sandwich Roof Panel PU Sealed Rock Wool Sandwich Roof Panel PU Sandwich Roof Panel

portal steel structure building wall Options

1) Color Steel Sheet

The simplest wall treatment. Because there is no insulation layer, it is not suitable to use as a living place. It is common in garages, agricultural sheds, simple warehouses, factories, and other industries or agricultural buildings.

2) Sandwich wall Panel

The use of the core plate as the wall material has the following advantages:

Inquiring about thermal insulation performance: The insulation and thermal insulation performance of the sandwich board are very superior. The insulation material filled in the middle can effectively isolate the indoor temperature difference, greatly reducing the coefficient of heat transfer, and improving the energy-saving effect of the building.

Construction is convenient and fast: the transportation and installation of the sandwich board are easier and easy to move, which can greatly shorten the construction period.

Environmental protection and energy saving: The insulation materials and substrates used by the sandwiches are mostly environmentally friendly materials. A large amount of garbage will be generated during the construction process to reduce environmental pollution. At the same time, due to the good thermal insulation effect during use, it greatly reduces energy consumption and achieves realization. Energy saving and environmental protection.

Lightweight and high strength: The thickness of the sandwich plate is thinner, and the weight is lighter than the traditional wall material, but the intensity is very high, which can meet the building’s requirements for the wall material.

Good decorative effect: The surface materials of the sandwich board can be treated according to personal preference, such as stuck stone materials, tiles, paint coatings, and other decorative methods, bringing good decorative effects.

Cost of Portal Steel Structure Buildings

Many people believe that the cost of steel structure buildings is equal to “steel unit price × weight”. However, the cost of steel structure buildings is not a fixed price and is influenced by a variety of factors.

Span and Column Spacing: The larger the span, the more steel is required; the smaller the column spacing, the more columns are needed. Finding the most economical dimensions while meeting requirements and safety is the key to achieving the lowest cost solution.

Height and Load: Higher building heights require deeper foundations and more complex installations, thus increasing costs. If the building needs to accommodate equipment such as cranes, the load-bearing capacity requirements of the structure are even higher, further increasing steel usage and costs.

We strongly recommend that you communicate and collaborate with professional steel structure suppliers or engineers as early as possible during the project design phase. Their extensive experience allows them to provide you with the optimal solution that balances safety, functionality, and economy.

Application of Portal Steel Structure Buildings

Industrial Steel Buildings

Agricultural Steel Buildings

Commercial Steel Buildings

Residential Metal Buildings

Reliable China Steel Building Supplier | K-HOME

K-HOME specializes in custom-designed steel portal frame structures, comprehensively meeting your building needs. We offer highly flexible customization services, designing clear span or multi-span frame structures according to the actual needs of your project, and supporting personalized adjustments to building dimensions, exterior colors, and door and window layouts.

Our steel structure products are manufactured in strict accordance with Chinese GB standards, while also possessing international adaptability. For overseas projects, our engineering team is proficient in international standards such as ASTM and EN, and will conduct professional structural verification calculations according to the standards of the project location to ensure full compliance with local building regulations.

All steel structure buildings undergo precise load calculations, possessing excellent structural performance and effectively resisting extreme weather conditions such as strong winds (up to category 12 typhoons) and heavy snow (up to 1.5kN/m² snow load). Whether it’s industrial plants, logistics warehouses, commercial centers, or sports stadiums, we can provide safe, reliable, and cost-effective steel structure solutions.

With extensive project experience and technical strength, K-HOME is committed to providing global clients with one-stop services from design consultation to production and installation, ensuring that every project achieves optimal quality standards and economic benefits.

Frequently asked questions

portal steel structure building projects show

SEND A MESSAGE