Pre-engineered Building manufacturer , supplier

pre-engineered steel building / prefabricated steel structure / steel structure building / steel construction building /

Pre Engineered Building | Steel Structure Buildings

The Pre Engineered Building is all composed of a cold-formed thin-walled steel component system, and the steel frame is made of super anti-corrosion high-strength cold-rolled galvanized sheet, which effectively avoids the influence of steel plate corrosion during construction and use, and increases the service life of light steel components.

Steel structure buildings can withstand harsh weather and require just simple maintenance, its service life up to 50 years. The PEB steel structure building has high strength, good overall rigidity, and strong deformability. The weight of the building is only one-fifth of the brick-concrete structure, and it can withstand a hurricane of 70 meters per second so that life and property can be effectively protected. Safety and reliability, good seismic and wind resistance, strong load capacity, and earthquake resistance can reach level 8. The steel structure PEB building is light in weight, which could reduce the basic cost. And has a fast construction speed, it can be completed and put into operation as soon as possible. The overall economic benefits are much better than that of the concrete structure building.

The steel structure PEB building of the house can be 100% recycled, and most of the other supporting materials can also be recycled, which is in line with current environmental protection awareness. All materials are green building materials that meet the requirements of the ecological environment and are beneficial to health. The steel structure building has simple and smooth lines with a modern feel. The wall panels are available in a variety of colors, and the walls can also be made of different materials, so they are more flexible.

Types of Frames for Prefabricated Steel Structures

K-HOME provides two mainstream frame types: frame steel structure and portal steel structure. To meet the structural requirements of different application scenarios.

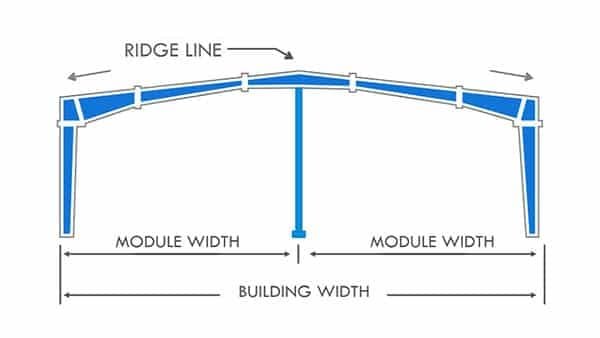

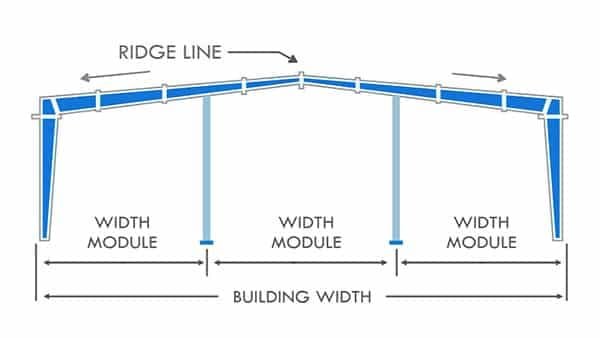

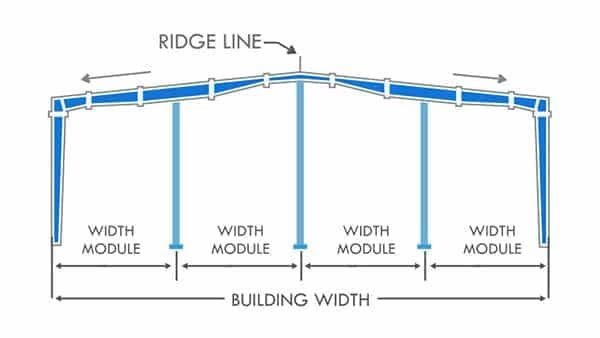

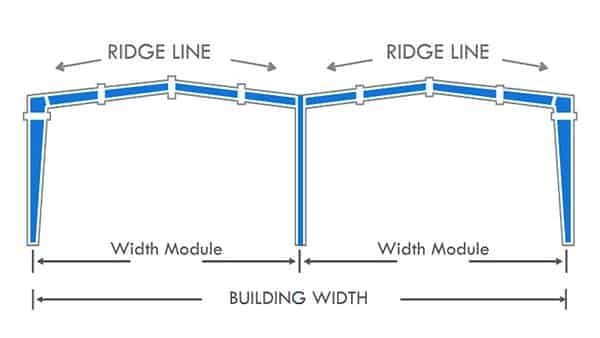

The portal steel frame adopts a large-span rigid frame design, which is composed of cross-section or variable-section H-shaped steel columns and steel beams. This structure can form an open space without intermediate support (within 30 meters in width), or it can be designed as a multi-span structure. It is particularly suitable for industrial plants, storage centers and logistics warehouses that require a wide internal layout. Its structural advantages are fast construction, cost-effectiveness, and flexibility to adapt to different span and height requirements.

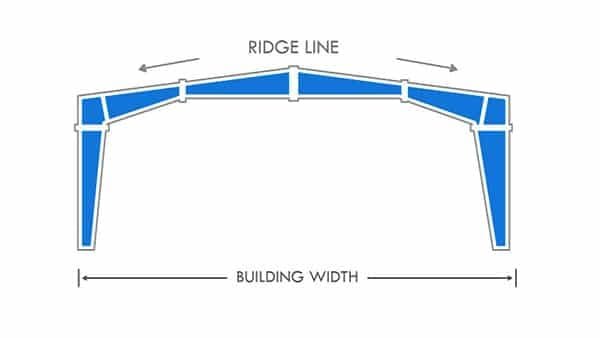

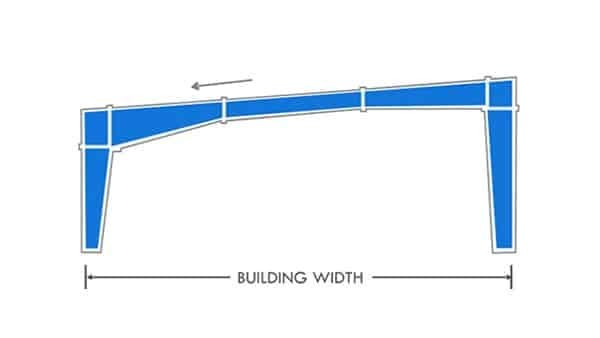

Portal steel frame type:

The frame steel structure constructs multi-layer or high-rise steel structures through standardized beam-column nodes, with stronger load-bearing capacity and seismic resistance. It is suitable for projects such as commercial buildings, office buildings and multi-story workshops that require higher structural stability.

Product Details

Steel Building Kits Options

The steel structure has many accessory options to consider, including heat insulation, shutters and ventilation fans, windows, doors, etc. In order to optimize the prefabricated construction system design, all options should be carefully considered.

- Roll-up door

- Double opening doors

- Windows

- Louvers

- Turbine Fan

- Ventilation

Other Building Kit Options

According to the durability and cost budget of the construction project, there are many types of structural kits to choose from.

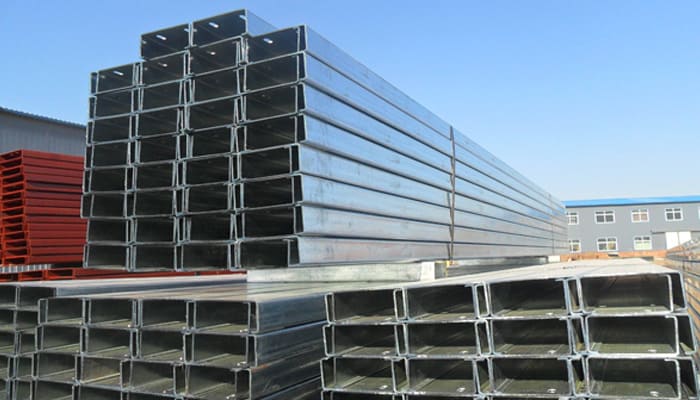

1. Choose a lighter steel frame. The light steel structure uses C-shaped channel steel instead of an I-shaped beam, which is suitable for areas with low wind and snow loads.

2. If it is a more solid industrial-grade building, I-steel construction is the most correct choice.

3. Choose suitable enclosure wall materials to shorten construction time and reduce costs.

Under the condition of ensuring safety, reducing the amount of steel used per ton can reduce your costs. Of course, this requires our professional team to plan the architectural design and calculate the quotation for you.

- C-shaped channel steel

- I-shaped Beam

- Sandwich Panel

| Main Steel Frame | Column | Q235, Q345 Welded H Section Steel |

| Beam | Q235, Q345 Welded H Section Steel | |

| Secondary Frame | Purlin | Q235 C and Z purlin |

| Knee brace | Q235 Angle Steel | |

| Tie Rod | Q235 Circular Steel Pipe | |

| Brace | Q235 Round Bar | |

| Vertical and Horizontal Support | Q235 Angle Steel, Round Bar, or Steel Pipe | |

| Maintenance system | Roof Panel | EPS Sandwich Panel / Glass Fiber Sandwich Panel / Rock Wool Sandwich Panel / Pu Sandwich Panel /Steel Sheet |

| Wall Panel | Sandwich Panel / Corrugated Steel Sheet | |

| Accessories | Window | Aluminum Alloy Window / PVC Window / Sandwich Panel Window |

| Door | Sliding Sandwich Panel Door / Rolling Metal Door / Personal Door | |

| Rainspout | PVC |

| Live load on Roof | In 120kg/Sqm (Color steel panel surrounded) |

| Wind Resistance Grade | 12 Grades |

| Earthquake-resistance | 8 Grades |

| Structure Usage | Up to 50 years |

| Temperature | Suitable temperature.-50°C~+50°C |

| Certification | ISO9001:2008, ISO14001:2004 |

| Finishing Options | A vast array of colors and textures is available |

| Paint Options | Alkyd painting, two primary painting, two finish painting (gray paint, red paint, white paint, epoxy zinc, etc.) Or Galvanized. |

Steel Building Kits Options Gallery

Our Services Include

Custom Design Solutions

Regardless of the size, color, or style of the building, you can rely on Khome’s custom engineered solutions to meet your needs.

Architectural Quotation

There are several factors that will affect the alternative cost of steel construction, please contact our professional team.

Installation Guidance

Don’t know how to construction? Don’t worry, we have professional engineers to guide you in installation. And from planning, design to construction, every step has detailed drawings design, Khome is committed to providing a one-stop service.

Who We Are?

K-home is committed to providing a one-stop delivery service for you. From domestic projects to global developments, we have extensive construction experience in design, engineering, fabrication, and project management.

Design Requirement

If you need a drawing design, please provide us the following basic parameters.

| 1 | Location (Where Will Be Built?) | _____Country, Area |

| 2 | Size: Length*Width*Height | _____mm*_____mm*_____mm |

| 3 | Wind Load (Max. Wind Speed) | _____kn/m2, _____km/h, _____m/s |

| 4 | Snow Load (Max. Snow Height) | _____kn/m2, _____mm |

| 5 | Anti-Earthquake | _____level |

| 6 | Brickwall Needed Or Not | If yes, 1.2m high or 1.5m high |

| 7 | Thermal Insulation | If yes, EPS, fiberglass wool, Rockwool, PU sandwich panels will be suggested. If not, the metal steel sheets will be ok. The cost of the latter will be much lower than that of the former |

| 8 | Door Quantity & Size | _____units, _____(width)mm*_____(height)mm |

| 9 | Window Quantity & Size | _____units, _____(width)mm*_____(height)mm |

| 10 | Crane Needed Or Not | If yes, _____units, max. lifting weight____tons; max. lifting height _____m |

pre engineered building solution for every need

pre engineered steel buildings have become the preferred choice in the field of modern industrial and commercial buildings due to their excellent cost-effectiveness and efficient construction performance. Compared with traditional concrete or brick-concrete structures, this type of building has significant advantages in many aspects.

First, prefabricated steel structures use standardized factory production components, which greatly shortens the on-site construction period, so that the time from design to delivery of the project can be reduced by 30% to 50% compared with traditional buildings, thereby significantly reducing labor costs and capital occupation pressure.

Second, the high strength and lightweight characteristics of steel itself make the building structure more streamlined, which not only reduces material waste but also optimizes the overall construction cost.

In addition, pre engineered buildings have excellent durability and low maintenance requirements. Through the treatment of modern anti-rust, anti-corrosion and fire-proof technologies, their service life can easily reach decades, and the long-term operating cost is much lower than that of traditional buildings.

In terms of application scenarios, steel structure buildings are particularly suitable for large-span and high-space building needs, so they are widely used in industrial plants, logistics warehouses, large supermarkets, stadiums and other places. Its flexible modular design allows the space layout to be quickly adjusted according to actual needs, and even later expansion or relocation can be achieved, which provides convenience for the sustainable development of enterprises. At the same time, steel structure buildings also have excellent earthquake and wind resistance, and can better demonstrate their safety and reliability in areas where geological disasters frequently occur.

Factors Affecting Steel Structure Building Costs

The cost of a prefabricated steel building is not a one-size-fits-all price; its cost is affected by a variety of factors. Each factor plays a vital role in determining the overall budget of a building project. Understanding these factors can help you make informed decisions and ensure that your building project is cost-effective and successful.

- Size and Complexity: The size of the steel building will affect the steel consumption, with larger sizes requiring more material, which naturally increases the overall cost. Second, the complexity of the building design will affect the cost, especially if specialized features are required. Custom designs and unique building elements will increase the total expense. You can consult us to get the most economical design.

- Materials and Finishes: The type and quality of materials used for the exterior and interior of a steel structure building can significantly affect the cost. High-end finishes and specialized materials can increase the budget, while standard options can help reduce costs.

- Location and Transportation: The cost of transporting steel structural kits to the construction site can vary depending on location and distance. Remote or hard-to-reach sites may incur higher transportation costs, so it is important to consider this in your budget.

To minimize costs and ensure your steel building is cost-effective, consider the following tips:

- Work with an experienced PEB manufacturer or contractor: Working with a professional who has experience designing PEB buildings can help optimize the design and materials, ensuring a cost-effective solution.

- Use standard components and features: Choosing standard components and features can reduce customization costs and simplify the construction process.

- Plan carefully to minimize shipping and labor costs: Efficient planning and logistics can help reduce shipping and labor costs, ensuring a more cost-effective project.

By understanding the factors that affect PEB costs and taking proactive steps to manage these costs, you can achieve a successful and budget-friendly construction project.

Pre Engineered Buildings Manufacturers and Suppliers

K-home is a professional manufacturer of Pre Engineered buildings in China. We have the qualifications of steel structure construction professional contracting grade two, building engineering general contracting grade two, building decoration project professional contracting grade two, and steel structure design, installation, and construction qualifications.

Our factory is located in Xinxiang, Henan, with a superior location and convenient transportation. We have the advanced production equipment, strong strength, reliable reputation, product quality control, guaranteed steel structure engineering quality, reasonable price, and can produce and process products of various specifications for customers for a long time, including welding and processing various large heavy steel, H Section light steel, box beams, box columns, steel structure workshops, and other businesses, and provide free product consultation and design services.