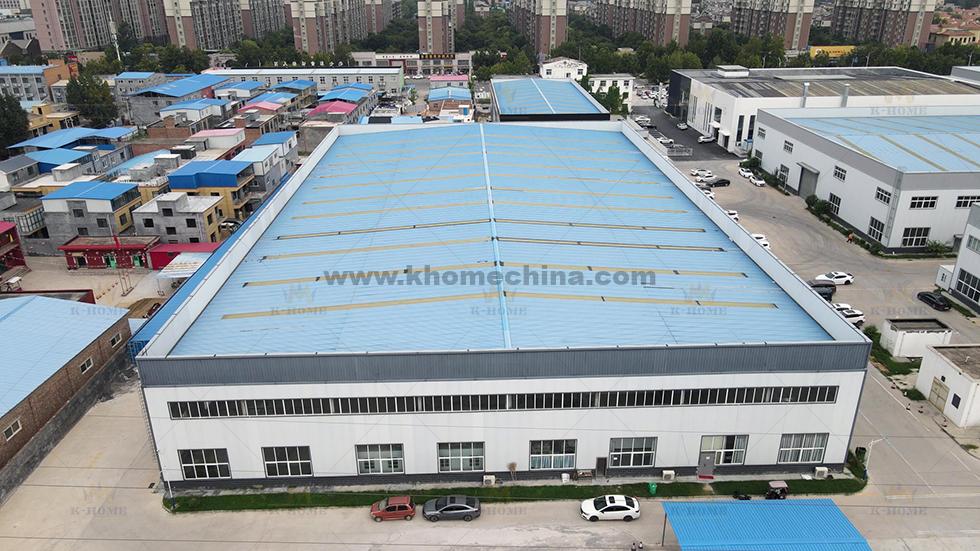

Affordable Metal Shop Buildings Kits

Are you looking for metal shop buildings manufacturer? At HENAN K-HOME STEEL STRUCTURE CO., LTD. we offer you a wide range of durable custom shop buildings kits for sale. These steel buildings are designed to meet your needs, including prefab steel structures and metal shop buildings kits. Our metal shop buildings are great workshops or commercial steel buildings.

You can contact us immediately to communicate with us to realize your metal shop building ideas. We can provide a one-stop service for you from engineering design, calculation, detail drawing, budget control, manufacture, delivery, and installation. Send us your demand and we will make a professional proposal for you based on our rich experience.

Product Details

| Main structure | H-section steel | Q345/Q235 steel H beam, Box column is also available |

| Welding | Automatic Submerged Arc Welding | |

| Rust removing | Shot blasting | |

| surface processing | twice primer and twice finish Alkyd Paint or hot dip galvanized | |

| High strength bolt | Grade 10.9 | |

| Substructure | Angle brace | L50x4, Steel Q235, Process, and painting |

| Cross bracing | Dia.20 round bar, Steel Q235, process and pre-galvanized | |

| Tie bar | Dia.89*3 round pipe, Steel Q235 Process, and painting or pre-galvanized | |

| Batter brace | Dia.12 round bar, Steel Q235 process and pre-galvanized | |

| Ordinary bolt | Galvanized bolt | |

| Roof | Purlin | C channel or Z channel, steel Q235, galvanized |

| Roof panel | (50mm, 75mm, 100mm, 150mm) Sandwich panel or corrugated GI color steel sheet | |

| Transparent skylight | 1.2mm FRP/customized | |

| Accessories | Sealant, self-tapping screw, etc. | |

| Edge cover | Made of color steel sheet | |

| Gutter | Made of steel sheet thickness 0.8mm, or PVC | |

| Rainspout | PVC pipe | |

| Wall | Purlin | C channel or Z channel, steel Q235, galvanized |

| Wall panel | (50mm, 75mm, 100mm, 150mm) Sandwich panel or (0.4mm, 0.5mm, 0.6mm, 0.7mm) corrugated GI color steel sheet | |

| Accessories | Sealant, self-tapping screw, etc | |

| Edge cover | Made of GI color steel | |

| Ventilator | unpowered axial-flow ventilator or monitor roof | |

| Door & window | Electric rolling door/sliding door, PVC/Alu. alloy window | |

| Crane | With or without crane, ranging from 5 tons to 20 tons |

Main parts of steel structure shop buildings construction

- Embedded parts, (to stabilize the structure of the plant)

- Columns generally use H-shaped steel or C-shaped steel (usually angle steel used to connect two C-shaped steel)

- For beams, generally C-shaped steel and H-shaped steel are used (the height of the middle product is determined according to the span of the beam)

- Purlin: C-shaped steel and Z-shaped steel are generally used.

- Supports and braces are usually round steel.

- There are two types of tiles, the first is a color steel tile. The second type is the composite sandwich board. (Polyurethane or rock wool is sandwiched between the two-layer color-coated board, which plays the role of warming in winter and cooling in summer, and also has the effect of sound insulation and fire prevention).

Metal Shop Buildings For Sale

How much does it cost to build a shop?

- According to actual needs, every 10 cm increase in building height will increase the cost by 2% to 3%.

- Building envelope structure, which is also a cost consideration, such as doors and windows, exterior walls, etc.

- The size of the building area is very necessary. A large amount of steel is needed, and the cost of the steel plant is relatively high. The width determines its size, which of course is closely related to the design structure of the workshop.

- The span of the steel structure. Generally speaking, the larger the span, the lower the cost. Of course, the span is arranged according to one’s own needs, the same is true for spans of different designs, and the requirements for column spacing are also very different.

- The design directly determines the number of materials used and the cost of the quotation. Therefore, the design of construction drawings and schemes must be rationalized. The main design influence is the design of basic design, steel beam design, column network design, and other aspects. Designers It is necessary to consider relevant factors to rationalize the design and quotation of the entire structure.

- Potential steel prices affect steel shop building price: Metal shop buildings price depends on steel availability and related pricing. K-HOME will make every effort to mitigate the cost increase due to the increase in steel prices.

how much does it cost to build a shop per square foot?

Metal shop buildings prices vary greatly depending on your needs. Since our steel shop building kits are custom-made, you can create your own prefab shop building. Generally speaking, the smaller the building area, the higher the metal shop buildings prices per square foot.

If you need a precise quote, please contact us and we will customize a solution of the most suitable steel building kits according to your exact specifications to obtain cheap metal building kits. Contact us now!

Metal Shop Buildings Advantages

Metal Shop Buildings Plans

Before building your own shop, first, confirm how much land you have and what size steel structure shop building you want. Measure the area where you plan to place your new metal shop, and then consider how your space will be used.

All K-HOME steel shop buildings are custom designed to meet the wind and snow loads at your location. This work is included in your building price, making the K-HOME steel shop building structure the strongest on the market.

Metal Shop Buildings Kits

Our metal shop buildings are highly customizable steel frame building kits, K-HOME can provide you with the most suitable metal shop buildings package. After sizing the building, you can customize the look of your steel shop building with different color schemes and add different parts depending on your purpose. You can also contact our professional design team for a custom design, including the size and color of your metal shop building kits. Your personal choice of accessories gives your base metal shop buildings a different character. You can build any building you want with K-HOME metal building kits and we’ll make it happen for you. Please send us an email to get your exclusive prefab metal shop building solution.

How does steel structure work?

There are five main types of structural members that make up a steel frame – tension members, compression members, bending members, composite members, and their connections.

The steel components are assembled into frames on site. The processes involve lifting and placing the components and then joining them together. Usually, this is done by bolting, but sometimes on-site welding is used.

Anchor bolt retest → steel component unloading → component entry inspection → car crane directly hoisted in place → anchor bolts are temporarily tightened → cable wind rope is temporarily tightened and stabilized → steel column axis position and verticality adjustment → steel column bolts and Column foot pressing plate tightening and welding → next steel column installation → steel tie rod installation → forming the first stable lattice system → steel roof truss ground assembled into a whole and two machines lifted in place to form the first steel roof truss → Symmetrical installation of columns and roof truss system on both sides, and so on. Installation is completed and the structure is checked and accepted.

Related Product

SEND A MESSAGE