Construction Camp in Ghana

Site Camp / Portable Labour Camp / Portable Man Campsr / accommodation camp / Oil Field Camps

Construction site Camp project in Ghana

This is a construction camp in Ghana, and it is built by prefabricated flat-pack containers. Containers are modular building units that can quickly build various use spaces according to needs, including residential areas, office areas, storage areas and other types of buildings.

This type of camp has excellent flexibility, customizability and environmental protection. Container buildings can be arbitrarily combined, spliced and laid out according to the terrain, scale and functional requirements of the camp, creating different functional areas such as reception centers, canteen, bathrooms, dormitory , etc. to meet diverse needs. In addition, modular camps also have the advantages of low cost, fast installation and mobility.

Due to the modular design, all parts of the containers are produced in the factory, and only assembly is required on site, which greatly shortens the construction cycle, allows the camp to be put into operation faster, reduces the preparatory time and cost, and improves the efficiency of capital turnover. In terms of safety, modular camp building has a stable structure and good fire, water, wind and earthquake resistance. It can withstand certain natural disasters and bad weather, and provide reliable safety protection for camp personnel and facilities.

Preliminary Plan Confirmation

In August 2023, we received an inquiry from a client and learned that the client was going to invest in a site camp in Ghana and needed to create office areas, dining areas, bathing areas, etc. for future staff in the short term.

Products that meet customer needs include containers and prefabricated houses. After a brief communication with him, we recommended prefab containers. The containers include models with different structures, detachable, flat-pack, and foldable type. At this time, the customer had not decided which one to choose. In September, the customer visited us for the first time. We introduced the characteristics and advantages of three different structural containers in detail in the office. After careful discussion and comparison, they finally chose the flat-pack container solution for the following reasons:

1. Fast Installation

The roof and floor are fabricated in the factory, and only to install wall panels, doors and windows on site, which makes the installation very fast.

2. Easy to Transport

Before loading at the factory, the components for each container units are packaged together, loaded as a whole, and transported as a whole.

3. Easy to Store and Manage On-site

Since the construction site is a newly developed open space, scattered items are easy to get lost. The components of each flat-pack unit are packed together, and easy to store and manage, so it will greatly reduce this situation. In addition, the flat-pack units are all marked before loading in the factory, which is easy to find during installation and improves installation efficiency.

Design Phase of Construction Camp

When customers have an initial idea, we can provide them with a customized design. Based on the client’s basic information, our designers will fully balance aesthetics, practicality, safety, etc., and customize the most ideal and economical solution for them through reasonable planning and layout.

1. Construction site Camp layout — Preliminary Design

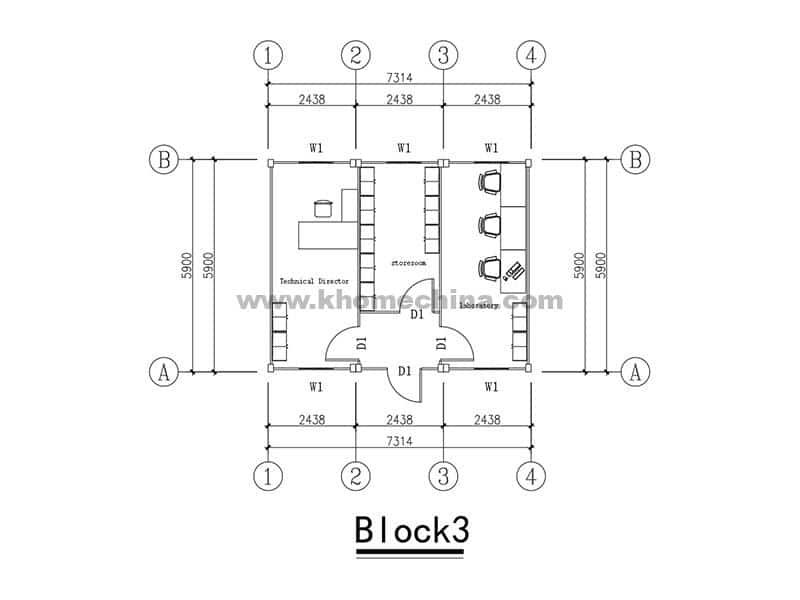

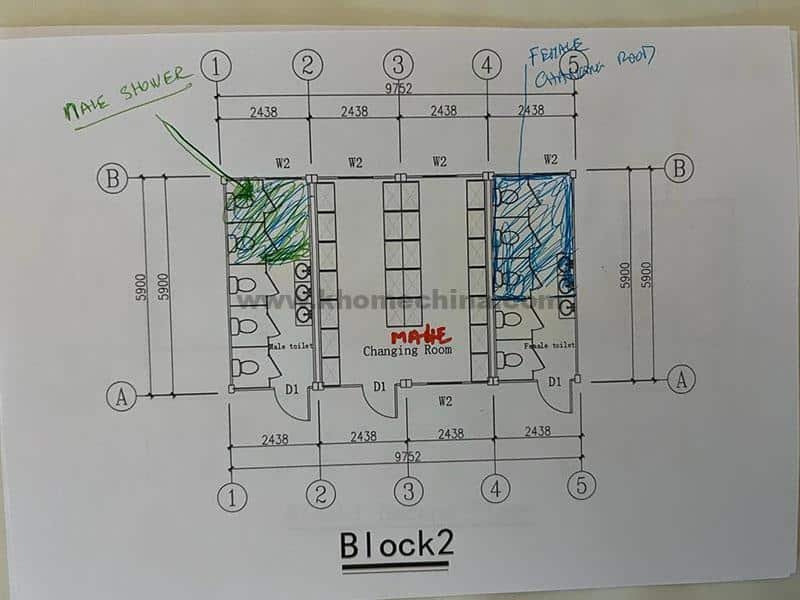

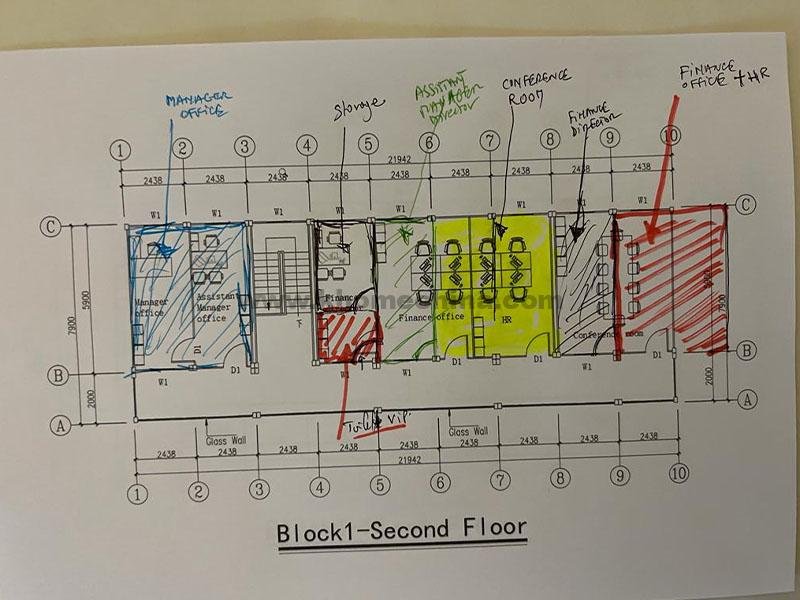

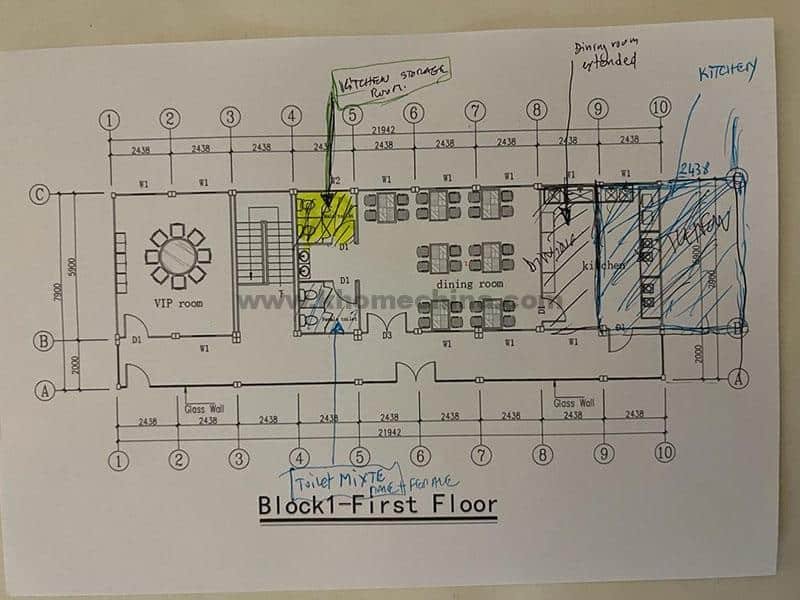

After the plan was confirmed, the customer sent the basic requirements for the modular camp building, asking it to include 3 functional modules. Based on these requirements, we made a preliminary design for him to confirm. The basic requirements and preliminary design are as follows:

2. Construction site Camp layout — Modification Design

After sending the preliminary design to the client, he had a more specific understanding of the layout of each functional area, and the architectural framework in his mind became clearer and clearer. Then he made modifications and additions to the design we sent as shown in the following figure:

According to the revised sketch, we adjusted and updated the design and sent it to the client again for confirmation.

3. Final Design

After more than two months of communication and revisions between us and the client, we finally confirmed the design for the modular camp.

4. Conclusion

When building a house, we all hope to get the most favorite and ideal design, so the confirmation of the drawings often takes a lot of time and effort. However, you don’t need to worry too much about these complicated processes. You just need to tell us your requirements, and our professional sales team and technical team will serve as your solid backing.

Confirm the Configurations of the construction Camp

Before implementing a project, customers often make an initial budget based on actual conditions and market research. We must provide customers with the most satisfactory solution within this budget, not only including the product selection and design confirmation but also the subsequent quotation. In the design stage, the layout and size of the modular building have been determined, and the next factor that affects the price is the configuration of each component of the house.

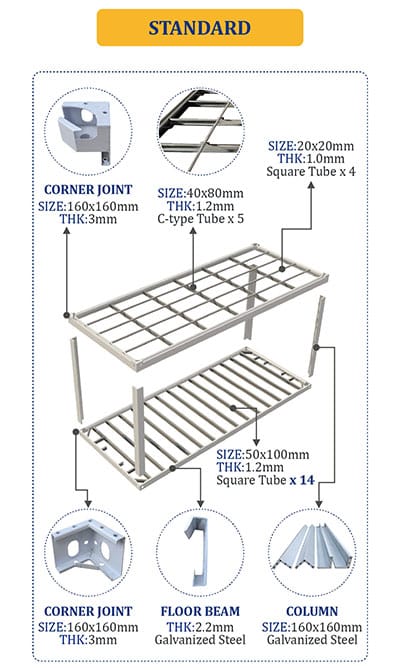

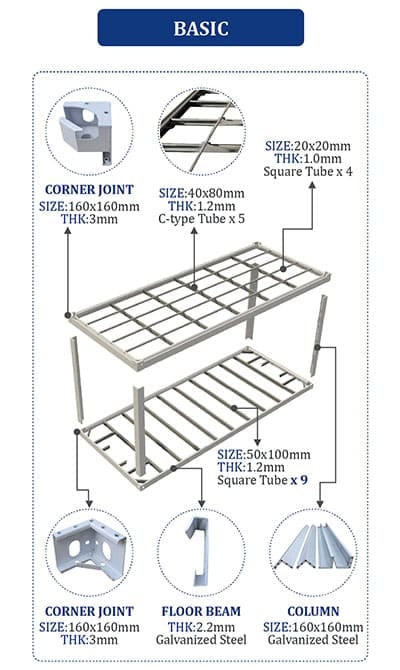

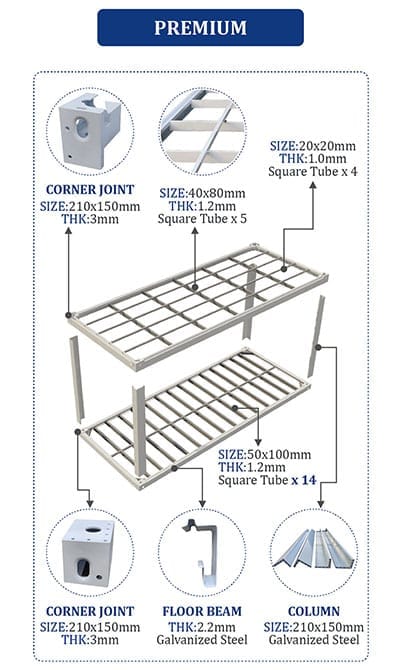

1、Basic Structure

Frame: The frame of the container house often adopts light steel structure. The thickness of the main steel frame can be customized, 2.3mm, 2.5mm, 3.0mm, etc. The thicker the thickness, the higher the cost.

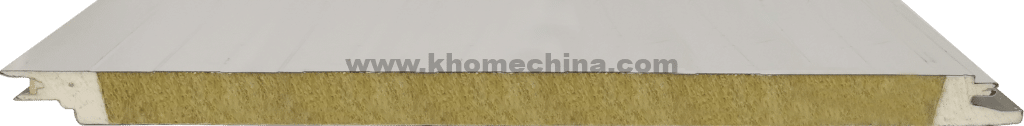

Enclosure: The wall uses composite sandwich panels, made of galvanized steel plates on both sides and thermal insulation core material, such as EPS foam, rock wool, polyurethane, etc. The thickness of the steel plate and the core material can be customized, affecting the price.

EPS Sandwich Panel Rock Wool Sandwich Panel PU Sealed Rock Wool Sandwich Panel PU Sandwich Panel

2、Decoration Structure

Decorative Wall Panels and Floors: The prices vary greatly depending on the selected materials, such as metal carved panels and anti-corrosion wood floors.

Doors and Windows: Except for the size and quality, the type of doors and windows (such as ordinary sliding or broken bridge aluminum), will all affect the price. High-quality, energy-saving doors and windows will cost more.

Interior Decoration: Water and electricity system: including materials such as wires, sockets, switches, etc.

Furniture and Equipment: Simple furniture such as beds, tables and chairs, as well as kitchen and bathroom equipment, etc. will increase the cost. All the facilities inside of Ghana modular camp buildings, including furniture, bathroom and kitchen facilities are provided by us.

For the Ghana camp, after communicating with the customer, the basic structure chose a premium configuration. As for the decorative structure, because the customer has requirements for both internal and external beauty, only the storage module and bathroom module use common configurations, while the office module and restaurant use high-end customized configurations. For example, the floor uses upgraded SPC flooring, the interior wall adds bamboo fiberboard and metal carved panels are added to the exterior wall for decoration.

Quotation and Contract Signing

Once all configurations were confirmed, we prepared a detailed quotation for the customer. After a thorough review and confirmation, the customer expressed satisfaction with our overall solution, noting that the price fit within their budget. Following this, the customer requested a proforma invoice and contract, and we received the deposit promptly.

Production and Transportation

Upon receiving the customer’s deposit, we will confirm the production drawings and begin production. Once production is complete, we will send pictures to the customer for inspection before they make the remaining balance. Since the delivery terms for the Ghana project are CIF, we will book the ship after receiving final payment. Before loading the container at our factory, we will conduct a thorough inspection and create a packing plan to ensure safe transportation at the lowest cost.

Construction Phase

Before the goods arrive at the port, our technical team will create comprehensive installation drawings and manuals to guide the process clearly.

If your team faces any issues during installation, we can offer remote support or send technicians on-site to assist. Our aim is to ensure smooth and high-quality construction, helping you efficiently complete your home for immediate use.

The Many Uses of prefabricated Container Houses

Container houses serve a wide range of purposes, making them highly adaptable. As a storage solution, they are perfect for businesses that need extra space for inventory or equipment. For construction sites, portable container units can house tools, machinery, and materials, reducing clutter and ensuring that items are secure. Additionally, temporary storage units can be used in emergency situations or during relocation processes, offering a convenient and portable option for storing goods.

On the other hand,container camp can also function as offices. Many businesses in Ghana are embracing these units as cost-effective alternatives to traditional office spaces. Whether it’s a small start-up or a construction company, these units provide a professional setting without the high costs of renting or building a conventional office building. The ability to customize the interior space with furniture, lighting, and technology makes these container houses the ultimate choice for a temporary office.Customize your own Design.

How to install A Container house step by step?

We offer various cabin container homes tailored to meet diverse customer demands. Our most popular options include detachable cabin container houses and flat-pack cabin container houses. The detachable version is wider, measuring 3 meters, compared to the flat-pack container house. As all the detachable container components can be disassembled, multiple sets can be configured into shipping containers to reduce transportation expenses, making it ideal for customers looking to minimize shipping costs. If you’re looking to save time, the flat-pack container houses, which come in a narrower 2.4-meter width, may be a more suitable option. The convenience of pre-installed roofs and bottoms in the factory provides onsite assembly, allowing for time and cost savings during the installation process. Both types of cabin container houses offer a comfortable lifestyle for residents. We ensure to provide the most cost-effective and efficient solution tailored to your individual needs and budget.

Why Choose K-Home?

K-Home is an integrated manufacturer that reduces procurement costs by eliminating middlemen. We prioritize quality, providing high-quality products along with comprehensive after-sales service.

With over ten years of experience in the construction industry, we offer prefabricated storage units that deliver excellent value. If you have any needs, please reach out, and K-Home will help make them a reality.

Frequently Asked Questions

Prefabricated container house projects show

container house in Djibouti

Learn more >>

container house in Guatemala

Learn more >>

SEND A MESSAGE