Flat Pack Container House

K-HOME is your one-stop shop for customizing prefabricated container houses.

What is the flat pack container house?

A prefabricated flat pack container house is a modular living space that is manufactured in a factory and then shipped to the site for assembly. These structures come in various configurations and are designed to be stackable, offering flexibility in terms of layout and design.

Prefabricated flat pack container homes are an affordable and sustainable option for you seeking an alternative to traditional housing methods. They are quick to assemble, taking only a few days to construct on-site, and require minimal labor and building materials. Additionally, they offer durability and insulation, making them suitable for a wide range of weather conditions.

The floor & roof of the flat pack container house is fully assembled in the factory, which includes the following aspects:

Flat Pack Container House Floor Structure

1) The Floor Frame

2) Cement Board

3) Glue

4) PVC Floor Leather

Flat pack container house roof structure

1) The Roof Frame

2) PE Film

3) Glass Wool

4) Roof Sheet

Flat Pack Container House enclosure system

Basic Door & Window

Sandwich Wall Panel

EPS sandwich and rock wool sandwich options can meet most using environments. If you have special requirements, PU sealed rock wool panel or PU panel can be recommended for your upgrade options.

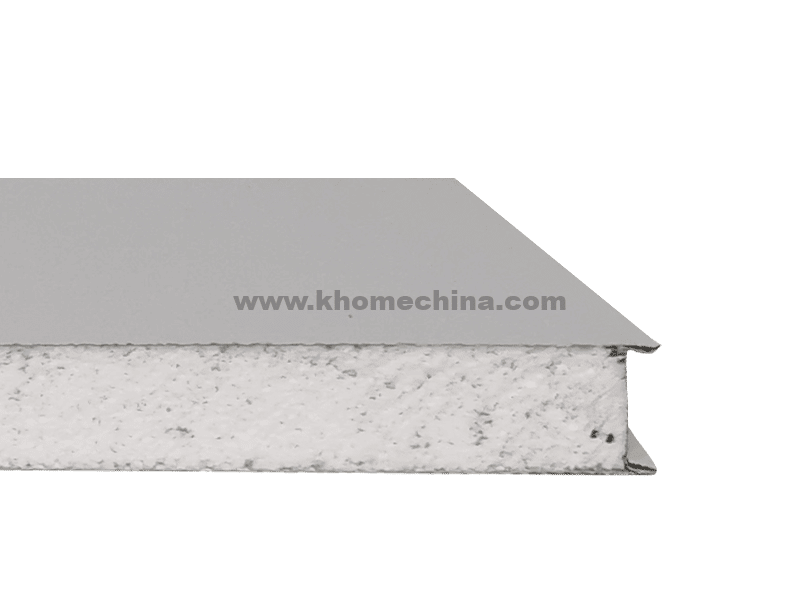

- EPS Sandwich Panel

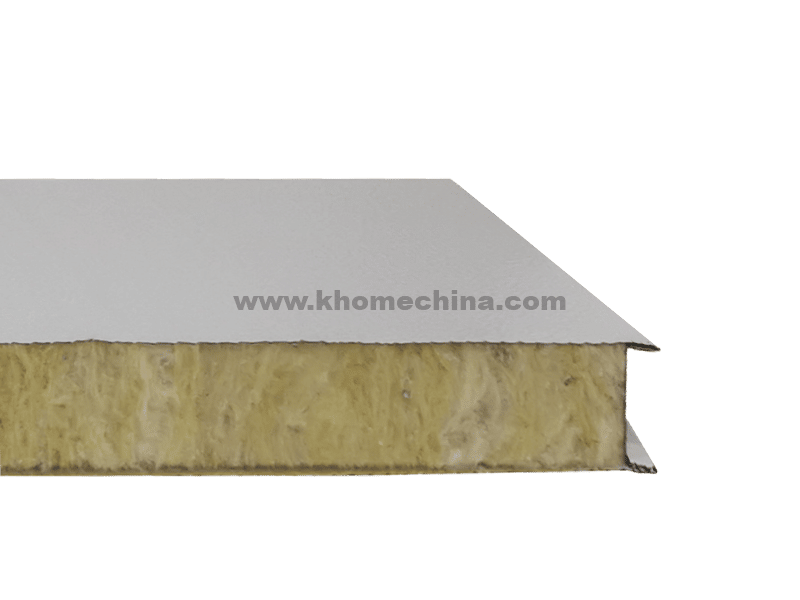

- Rock Wool Sandwich Panel

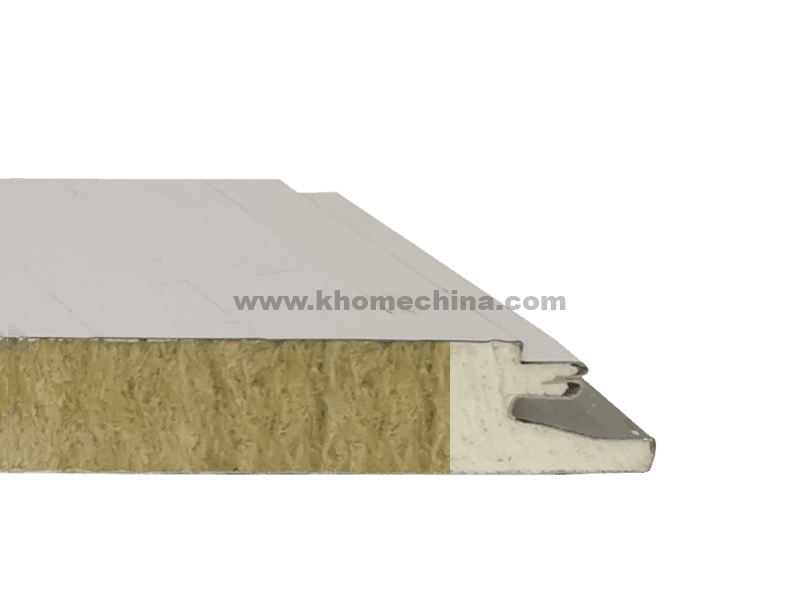

- PU Sealed Rock Wool Sandwich Panel

- PU Sandwich Panel

Waterproof

★ ★ ★ ★ ★

★ ★ ★ ☆ ☆

★ ★ ★ ★ ☆

★ ★ ★ ★ ★

Fireproof

★ ★ ★ ☆ ☆

★ ★ ★ ★ ★

★ ★ ★ ★ ★

★ ★ ★ ★ ☆

Heat Insulation

★ ★ ★ ★ ☆

★ ★ ★ ★ ☆

★ ★ ★ ★ ☆

★ ★ ★ ★ ★

Sound Insulation

★ ★ ★ ☆ ☆

★ ★ ★ ☆ ☆

★ ★ ★ ★ ☆

★ ★ ★ ★ ★

Cost Effective

★ ★ ★ ★ ★

★ ★ ★ ★ ★

★ ★ ★ ★ ☆

★ ★ ★ ☆ ☆

how to transport and install the flat pack container house?

Packing and transporting a flat pack container house is a straightforward process, with a few key steps to follow. Here’s a step-by-step guide:

1)Gather your tools: You’ll need a forklift, straps, and a truck or trailer capable of carrying the container.

2)Prepare the foundation: The container will arrive in a flat pack and needs to be assembled on a flat, level surface. Make sure your foundation is ready before the container arrives.

3)Assemble the container: Follow the manufacturer’s instructions to assemble the container. This will involve connecting the walls, roof, and floor panels and adding windows and doors as necessary. Ensure that the container is strongly secured to the foundation.

4)Disassemble the container: Once the container is fully assembled, you’ll need to take it apart again to transport it. This involves removing the doors and windows, disconnecting the panels, and packing everything carefully.

5)Pack the container for transport: Use straps to secure all the panels and components together, and stack them neatly in such a way that they won’t shift around during transport. Make sure the container is stable and balanced for safe transportation.

6)Load the container: Use a forklift to carefully load the packed container onto a flatbed truck or trailer. Make sure that the container is balanced and that the weight is distributed evenly.

7)Transport the container: Drive the container to its destination carefully, avoiding any sharp turns or sudden movements. Once you arrive, carefully unload the container using a forklift and reassemble it according to the manufacturer’s instructions.

With these steps, you can safely pack and transport your flat-pack container house to its destination.

What affects the flat pack container house price?

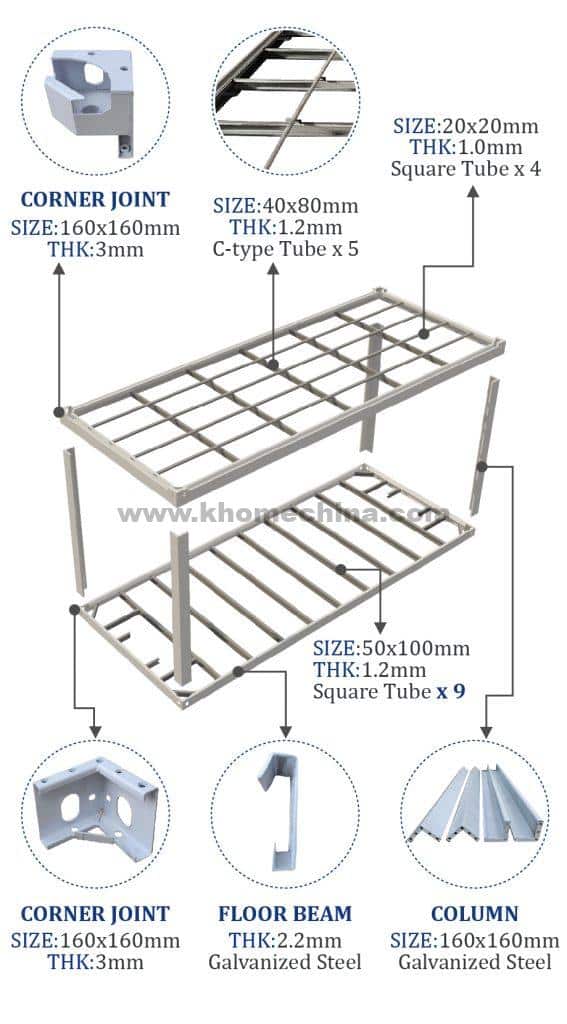

Different Parts Of Steel Frame

Flat Pack Container house basic Flat Pack Container house standard Flat Pack Container house premium

Flat pack container house price

The price only includes the container houses, windows, doors, lights, PVC floor leather, and stairs, not including furniture and shipping costs. The following table is the price reference of different configurations.

Basic

Standard

Premium

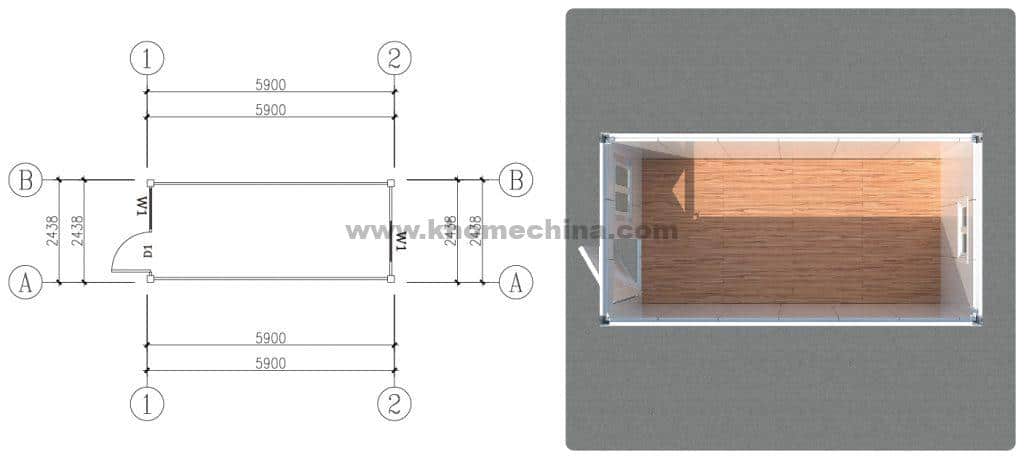

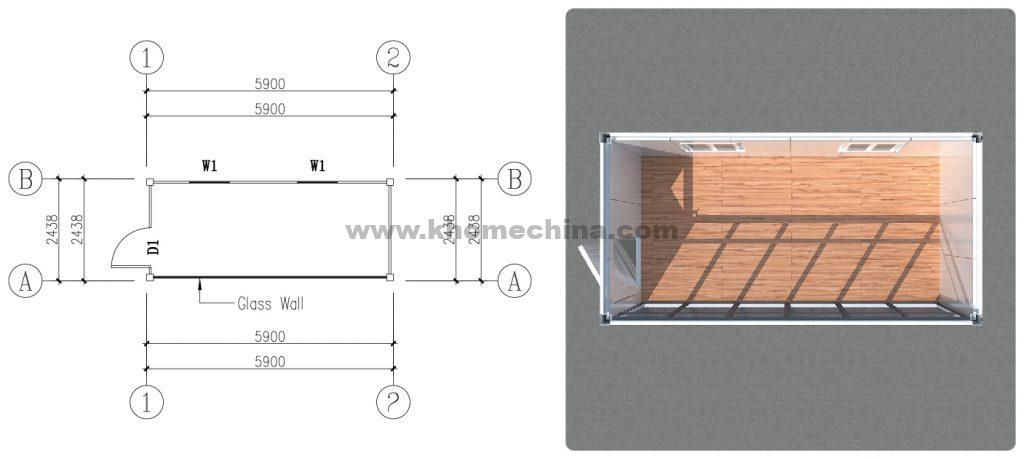

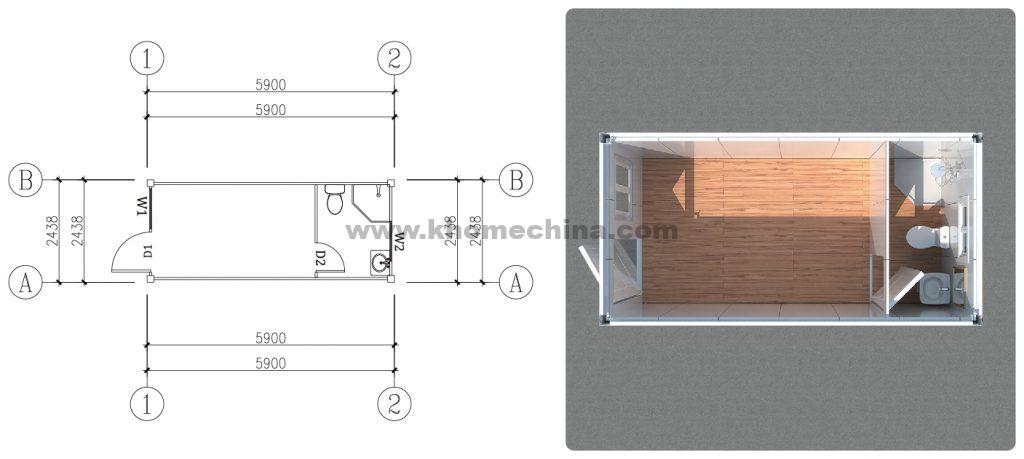

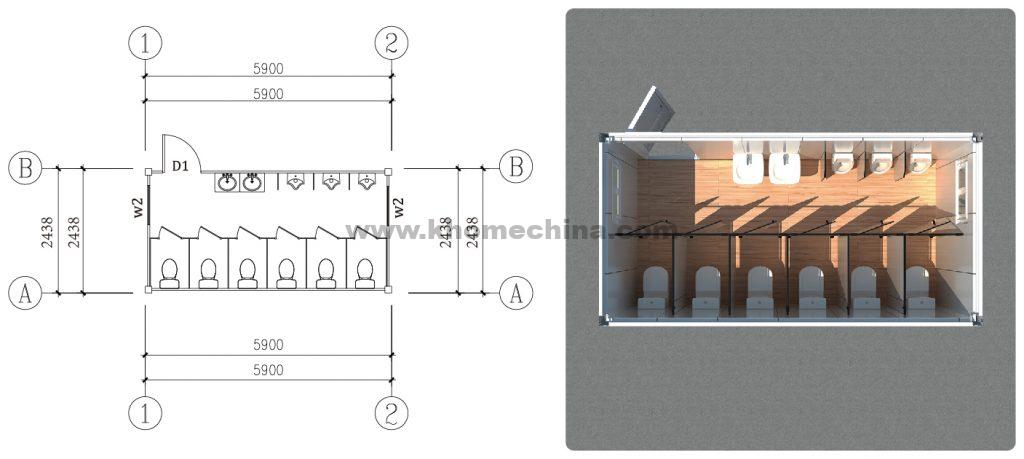

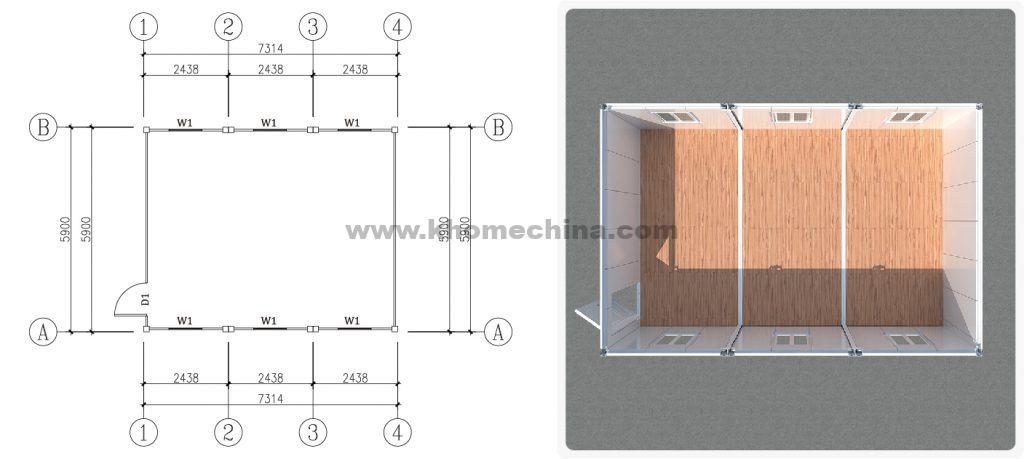

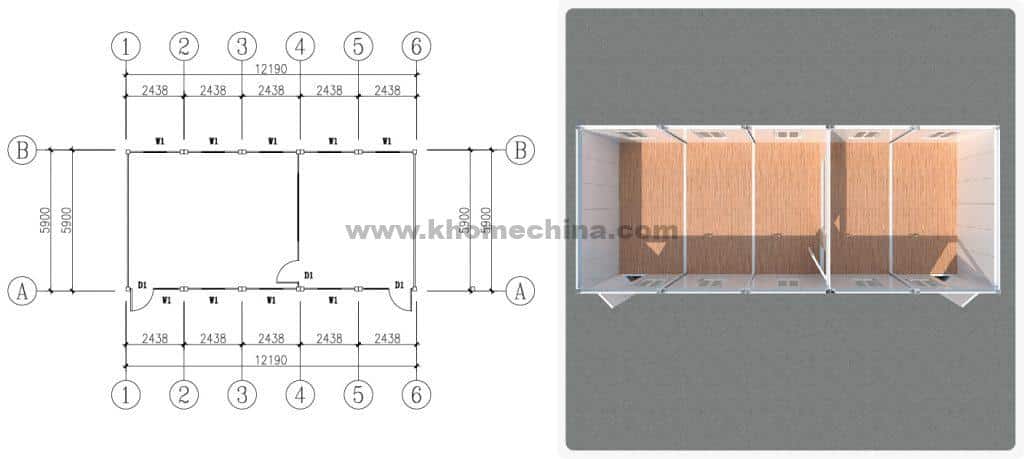

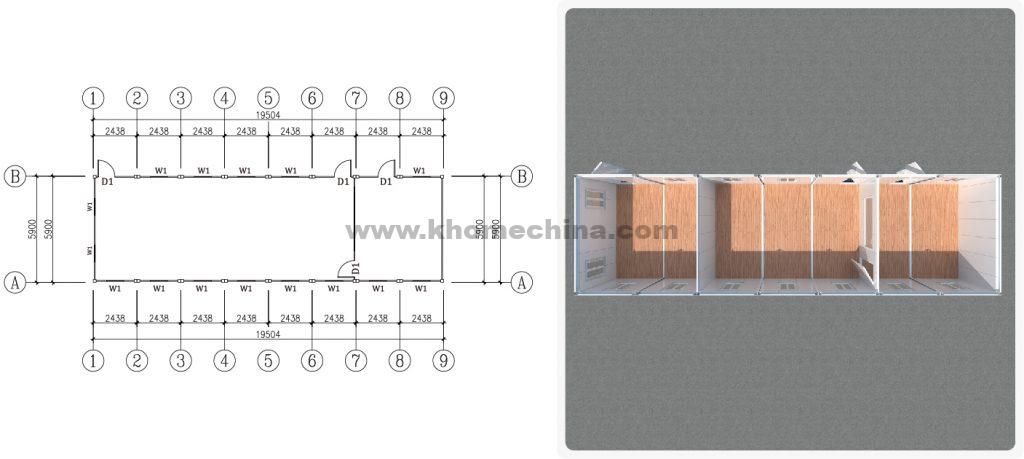

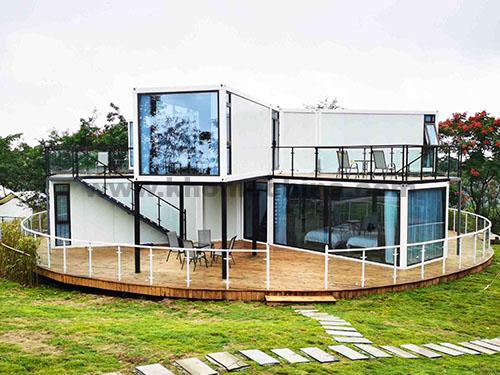

Flat pack container house Design

Two floor flat pack container house with terrace Two floor flat pack container house with slope roof Two floor flat pack container house with glass wall corridor container

K-HOME flat pack container house manufacturer

Prefabricated flat Pack container house projects show

SEND A MESSAGE