Construction Site Containers

Site Office Container / Container Site Office / Site Container Office / Construction Site Container Office / Construction Site Accommodation

What is a construction site container?

Construction site containers, also called construction containers, site containers, or on-site storage containers, are temporary buildings made just for construction sites. These containers are made of strong steel, which makes them tough and able to handle the rough conditions of construction sites. Construction site containers can be set up quickly, moved at any time, and are easy to install. They provide a fast, practical solution for building projects.

These on-site containers provide a secure and comfortable space for project managers, engineers, supervisors, and workers to rest, and collaborate. By deploying construction site containers, the modular offices provided ample space for project meetings, while the dormitories and amenities ensured that workers had a comfortable and secure resting place. This not only improved communication and collaboration among team members but also streamlined logistics and reduced travel time between different sites. Construction site containers can be designed with dedicated washrooms, showers, and changing facilities, promoting good personal hygiene among workers, and ensuring a healthier and safer work environment.

- construction site container

- Site Containers

- Construction Containers

- construction job site storage

- Construction site bungalow container

- On-Site Construction Container

- Construction site container building

- On-Site Storage Container

- construction site portable container

6 Reasons to Use Container Houses on Construction Sites

Using construction site containers has many benefits, especially in tough site environments. From cost-effectiveness to durability, their modular design allows for versatile construction solutions.

- Durability of containers: Construction site containers are made of high-quality steel. They have a sturdy structure that can withstand harsh weather and construction site environments. providing basic safety guarantees. This durability also extends the life of containers, allowing them to be reused for multiple projects and saving long-term costs.

- Easy installation of containers: Construction site containers can respond quickly to needs. They are built off-site in controlled conditions. No complex construction is required on-site, avoiding many time-consuming stages in traditional construction. Once arrives at the construction site, the container can be assembled and put into use quickly. This fast installation method saves time and allows for quick responses to urgent needs on the job.

- Flexibility of Containers: Flexibility is a major benefit of construction site containers. They can be adjusted, moved, or reconfigured as needed during different project stages. Whether used as offices, employee accommodation, or storage space, containers can quickly adapt to various changes and meet the needs of different locations.

- Highly Customizable Containers: Containers can be modified to meet the varied needs of construction sites. These containers can be partitioned internally, and equipped with electricity, lighting, ventilation equipment, and even air conditioning systems to provide a comfortable work and rest area for staff. Their adaptability means they can be turned into multi-functional spaces, suitable for the multi-purpose needs of construction sites.

- Cost-effective of containers: Prefabricated container houses are low-cost temporary buildings. Compared with traditional buildings, they can save 30% of construction costs. They can also be moved from one site to another for reuse, cutting project expenses. Additionally, construction site containers are low-maintenance, typically only needing regular checks and simple upkeep, making them cost-effective for long-term use.

- Environmental friendliness of containers: As the global focus on environmental sustainability intensifies, construction site containers are increasingly being designed with eco-friendly materials and practices in mind. prefabricated in the factory and installed on-site reducing the carbon footprint associated with production. Additionally, the modularity and reusability of these prefab mobile containers contribute to waste reduction and resource conservation. When a project is completed, the modular containers can be easily dismantled, transported, and reused on another site, minimizing the need for new construction materials and disposal of waste.

How to choose a suitable Construction Site Container?

Modular container are an effective solution for temporary housing on construction sites. These modules are highly flexible and easy to stack. The modular container system is designed as standardized modular units that can be combined and split according to actual needs to meet the spatial requirements of different scenarios. The module units are connected through standardized connectors to form a stable overall structure. K-HOME recommends three commonly used prefabricated container units:

Detachable container house: With flexible dimensions, modular units of different specifications and materials can be customized according to customer needs. The standard size is 3x6m, and standardized module units improve production efficiency. In addition, this type of modular container unit is disassembled for transportation, and each sea container can accommodate more units, reducing transportation costs.

Flat pack container house: The size is fixed, and the top and bottom have been pre-installed in the factory, reducing the difficulty and time of on-site construction and reducing manual labor costs. Due to the overall packaging and containerization, the size is relatively small and can only reach 2.4x6m.

Folding container house: with fixed dimensions and fixed door and window positions, almost all installation steps have been completed in the factory. When you receive the goods, you only need to connect the walls to each other, and the size is also 2.4x6m. Greatly reduces installation difficulty and labor costs. However, such a design requires all layouts to be determined before production and cannot be arbitrarily changed, resulting in low flexibility.

Regardless of the prefab container house design, the frame is composed of steel, and sandwich panels are used as the enclosure. The appearance similarity is high and the area difference is not significant. It is a modular design, and this modular container system is easy to expand and move, making it a high-quality choice for your temporary construction. Please contact K-HOME for your exclusive plan

Construction site Container Design

Construction site containers are designed to be cost-effective and practical, with a simple, functional appearance. Built to be durable, these containers are perfect for construction sites and remote locations. They can stay in good condition even in harsh environments. While the look is basic, these containers can be customized to create multi-functional spaces. They can be used for storage, office space, and staff dormitory, covering all the basic needs of a job site.

Most construction site containers are standard sizes, making them easy to stack and transport. The modular structure also allows for vertical or horizontal arrangements, creating single or multi-level setups as needed.

Construction containers can be further customized to enhance both functionality and appearance. For example, you can add extra doors or windows or change the exterior decoration. These personalized ideas improve the site’s look and help make the container reflect the company’s brand without losing any practicality.

We offer personalized design services at K-HOME to meet your unique needs and preferences. Imagine being able to see your container’s design through CAD drawings and 3D renderings before it’s even installed—it’s a reassuring experience! Contact K-Home today for an exclusive container design that’s sure to exceed your expectations!

Versatile Container houses on Construction Sites

Construction site containers are more than just a storage solution. They serve a variety of practical purposes on construction sites and are a flexible solution to various needs in construction projects. Strong and durable, quick to install and easy to move, containers can be easily adapted to various uses:

Construction Site Container Offices

Construction site container offices offer remarkable flexibility in terms of layout and design. From single-container offices to multi-container complexes, these container office structures can be combined to suit various needs, including administrative offices, meeting rooms, break rooms, and storage facilities.

K-HOME has a professional design team that can tailor a solution based on the scale of your project, the number of employees and specific needs. For example, the number of single offices, the number of people that need to be accommodated in public offices and meeting rooms, you don’t have to think too much, K-HOME can make a preliminary plan for you and make continuous modifications based on this to meet your expectations for the construction site container office building. If you have specific needs, please let us know in advance and we will provide you with the most suitable construction site office building plan within your budget.

Construction Site Container Accommodation

Container accommodation on construction sites provides a versatile, cost-effective and efficient temporary housing solution for construction sites, which can not only meet housing needs, but also improve overall project efficiency and worker welfare. Container accommodation, also known as modular or container housing, takes advantage of the modularity of standard containers, and makes reasonable layout and stacking to provide comfortable and practical living space for construction sites. These construction site container accommodations are fully equipped with facilities such as beds, lockers and even ensuite bathrooms. Due to the removable nature of prefabricated containers, construction site containers can be reused for multiple projects, can be moved at any time, and are fast to deploy and easy to relocate, greatly reducing installation and removal costs. This flexibility is particularly beneficial for time-sensitive projects or projects located in remote areas with limited traditional housing options.

Construction site container accommodation provides workers with a safer living environment, protects them from severe weather, and ensures that their accommodation remains habitable even in adverse conditions. According to customer feedback, our prefabricated construction site container units can withstand instantaneous gales of level 15. From the video, many of the cooked ones were broken, but our boxes remained intact without displacement or damage. You can contact us for relevant videos.

Construction site container accommodation represents an efficient and economical solution for temporary housing on construction sites, which can not only meet the housing needs of workers, but also improve overall project efficiency and worker welfare. If you also need a construction site container, please contact K-HOME, we are at your service at any time.

Construction site containers for canteen

While improving productivity on construction sites, dietary support is also important. That’s why canteens are a must-have area. Together with other facilities, they form a complete camp layout. There are several ways to build canteens, and using containers is an efficient choice.

The advantage of container canteens is that they are quick to build and cost-effective. These canteens are prefabricated outside the site, then transported to the site, and can be quickly put into use with simple bolt connections. They are designed to provide food service for construction site employees and ensure a good dining environment.

Inside the containers, there can be kitchens, dining areas, and even storage spaces for food and drinks, all set up to keep food safe and clean. As a flexible and convenient solution, container canteens can be set up and ready to use very quickly, making sure workers can easily get their meals even during busy workdays.

Construction site containers for Toilet

Compared to traditional building methods, site containers are cheaper and offer a wider range of options. When used as toilets on construction sites, these construction site containers can be fully customized and modified with comprehensive designs. During the conversion process, pipes and sanitary facilities can be installed in the containers, making them suitable as temporary toilets or showers for workers at the site.

At K-HOME, we use advanced manufacturing techniques and materials to produce high-quality and durable toilet facilities. These facilities usually come with a series of standard designs, as well as customization options to meet specific requirements. They can be used as standalone units or integrated into larger facilities, such as temporary office spaces or accommodation camps.

Since container houses have a sturdy structure and good corrosion resistance, these sanitary containers not only have a long lifespan but also require low maintenance costs. This makes K-HOME’s container toilets an ideal choice for construction sites and other places that need temporary yet reliable sanitary facilities. If you’re planning to start a project, you can contact us to get detailed information and quotes.

Do construction site containers require foundations?

The foundation of a construction site container depends on your needs. There is no one-size-fits-all approach. If you plan to keep the container in one place for a long time, using a concrete foundation can be an efficient and economical choice. As a premium container house supplier, we need to address all of our customers’ needs. We have made a variety of foundation plans for your reference. You can choose according to the actual situation of your project.

Our construction container structures can be placed on any type of terrain regardless of weather or other external variables. Their durability sets them apart from other traditional workplaces and prefabricated modular office structures.

- Foundation Solution-Dot Pillars

- Foundation Solution-Strip

- Foundation Solution-All Hardened

Construction Site Containers Advantages

How to Install a Construction Site Container?

Our most popular choices include detachable container houses and flat-pack container houses. Compared to flat-pack container houses, detachable container houses are wider and 3 meters long. Since all detachable container components can be disassembled, multiple sets of containers can be configured into a container to reduce transportation expenses, making it an ideal choice for customers who want to minimize transportation costs. If you want to save time, a flat-pack container house with a narrower width of 2.4 meters may be a more suitable choice. The factory-pre-assembled roof and bottom facilitate on-site assembly, saving time and cost during the installation process. Both types of container homes can provide residents with a comfortable lifestyle. We ensure that we provide the most cost-effective and efficient solution based on your individual needs and budget.

Construction Site Container Price

The price of a container is not fixed, but varies according to its size, functional configuration, and whether it needs to be customized. For projects with limited budgets, choosing a low-cost container option is an economical consideration. However, while pursuing price advantages, it must be remembered that the construction site is an environment that requires extremely high durability and functionality, so there must be no compromise on quality. If you want to know more about configuration and price, you can contact us for detailed information.

Why choose K-HOME construction site containers?

As a leading construction containers manufacturer in the industry, we adhere to the development concept of efficiency, flexibility and sustainability. Every innovative breakthrough is a manifestation of our deep understanding of the prefabricated housing field.

K-HOME’s construction site containers, crafted from thickened steel and rigorously designed for stability & safety, undergo stringent quality control throughout production, adhering to the highest standards. Their modular design ensures swift on-site assembly, expediting construction timelines to allow for a swifter focus on business development. Our cost-effective solution compared to traditional methods not only saves resources but also offers full customization in size, layout, decoration, and functionality, tailored to your unique needs.

K-HOME not only provides high-quality Prefabricated container houses but also has a professional pre-sales consultation, in-sales service, and after-sales support team. No matter which stage you encounter problems, we can respond quickly and provide you with the most considerate solutions. We believe that only by truly being customer-centric can we win your long-term trust and support.

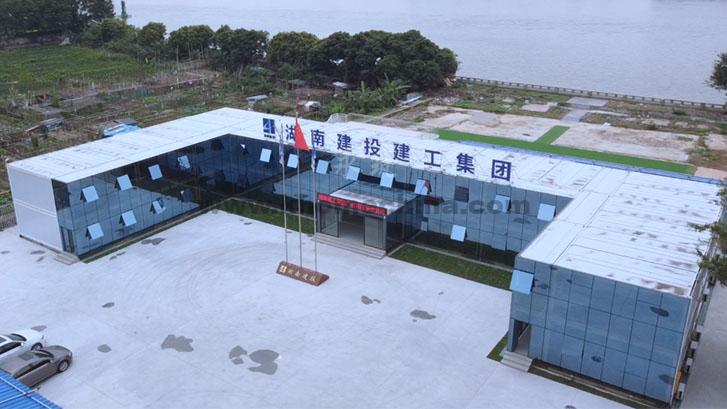

Related projects

SEND A MESSAGE