flat pack containers

20ft flat pack containers / 6m flat pack containers / flat pack container house / flat pack storage container / flat pack containers Manufacturer

Container house china – flat pack containers for sale from K-HOME

Flat-pack containers are modular container houses consisting of cold-bent galvanized steel frames and steel-insulated wall panels. The floor and ceiling are constructed in an integrated manner. This structure greatly simplifies the installation process and improves construction efficiency. Compared with detachable container houses, prefabricated flat-pack containers are easier to deploy quickly. They are widely used in scenes such as construction sites and remote sites as temporary offices, dormitories, or storage spaces.

The flat pack containers for sale by K-HOME are usually available in standard sizes (such as 20 feet and 40 feet) as well as customized options. Users can adjust the internal layout, door and window locations, and insulation performance according to their needs. Flat-pack modular buildings are ideal for temporary and mobile building solutions due to their efficient construction and environmental protection and energy saving.

20′ empty flat pack container 20′ empty flat pack container with bathroom 20′ empty flat pack container with bathroom 20′ flat pack container- accommodation

Capacity:1 person20′ flat pack container- accommodation

Capacity:1 person20′ flat pack container- accommodation

Capacity:2 person20′ flat pack container- accommodation

Capacity:8 person20′ flat pack container office 40′ flat pack container office 20′ flat pack container toilet 20′ flat pack container toilet for male&female 20′ flat pack container shower

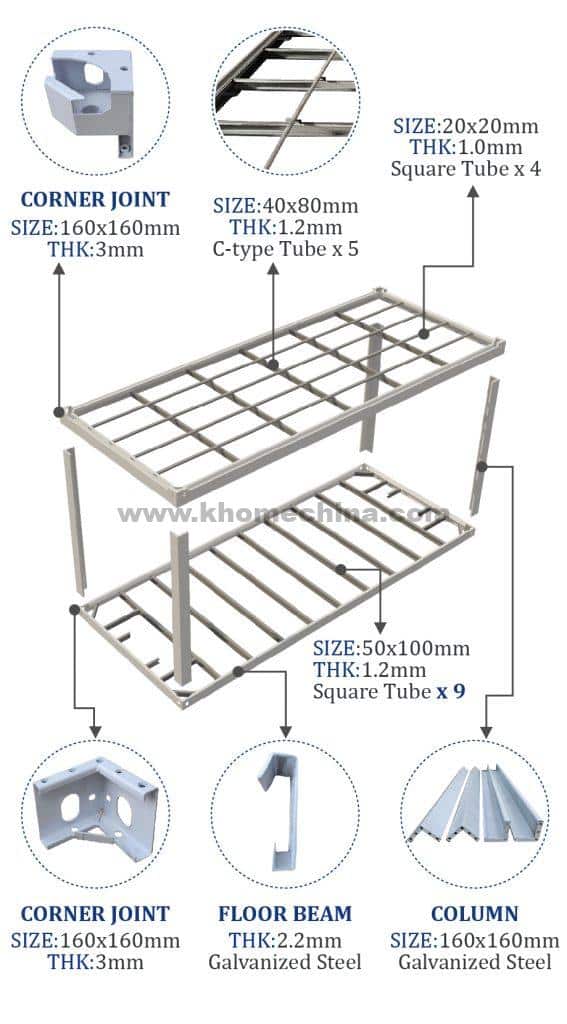

Structural analysis of standard 20ft flat pack containers

If you disassemble a standard packing box, you can divide it into four core components: top cover, bottom plate, support structure, and enclosure structure. Each component has been precisely designed and industrially produced to ensure structural stability and functional practicality. The following is a detailed disassembly analysis:

Roof structure

The roof is usually made of galvanized steel sheets pressed into corrugated sheets with rock wool insulation embedded inside. From bottom to top, they are galvanized ceiling steel sheets, roof main frame, 50mm thick insulation wool, and top galvanized roof panels. The roof beams are designed with drainage grooves around them, and rainwater can flow out along the drainage grooves to prevent accumulation on the roof. This design not only has excellent waterproof performance, but also can effectively keep warm and insulate.

- flat pack container-ceiling

- flat pack container-roof frame

- flat pack container-PE film

- flat pack container-insulate rock wool

- flat pack container-roof structure

floor structure

The floor system is made of cold-bent galvanized steel beams and has a #-shaped main frame, with a maximum load-bearing capacity of more than 30 tons (standard payload is about 30 tons). The ground is paved with 18mm thick high-density cement board, and the surface is covered with PVC floor leather. They can effectively block moisture penetration and ensure that the ground is dry and durable.

- flat pack container-floor frame

- flat pack container-18mm cement board

- flat pack container-PVC floor leather

Support structure

Galvanized steel columns are set at the four corners of the container. They are connected to the integral roof and the floor through high-strength bolts to form the overall frame of the container house. At the same time, drainage pipes are set in the surrounding steel columns to ensure that rainwater can flow smoothly to the ground to avoid water accumulation.

Enclosure structure (wall panels, doors, windows)

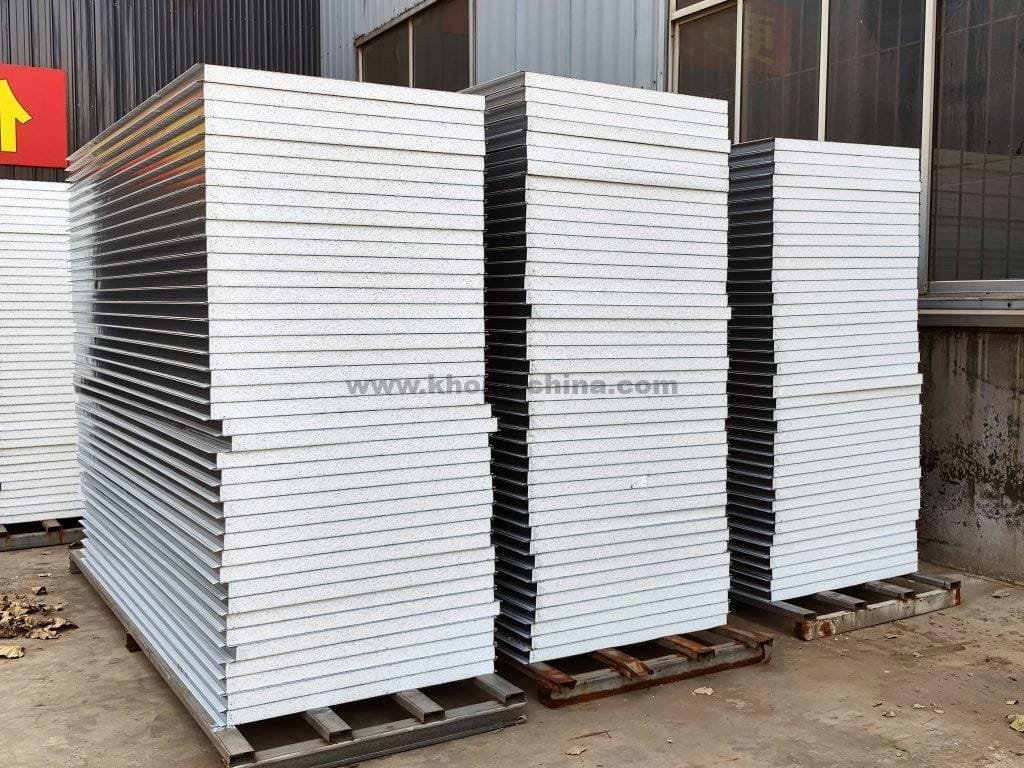

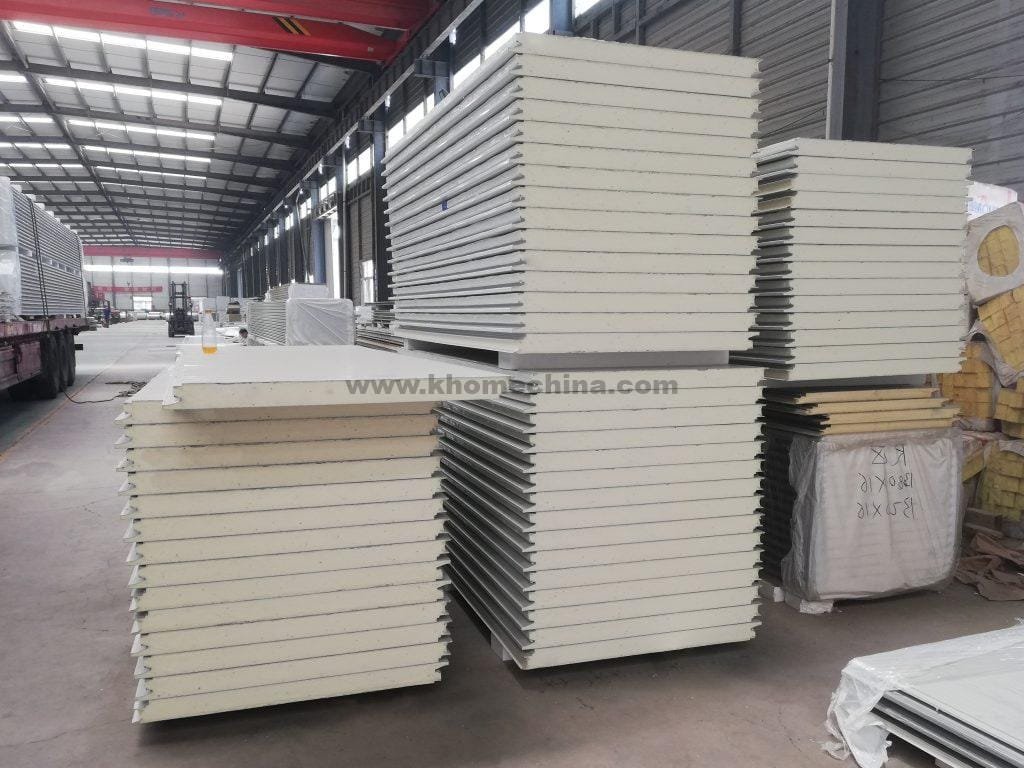

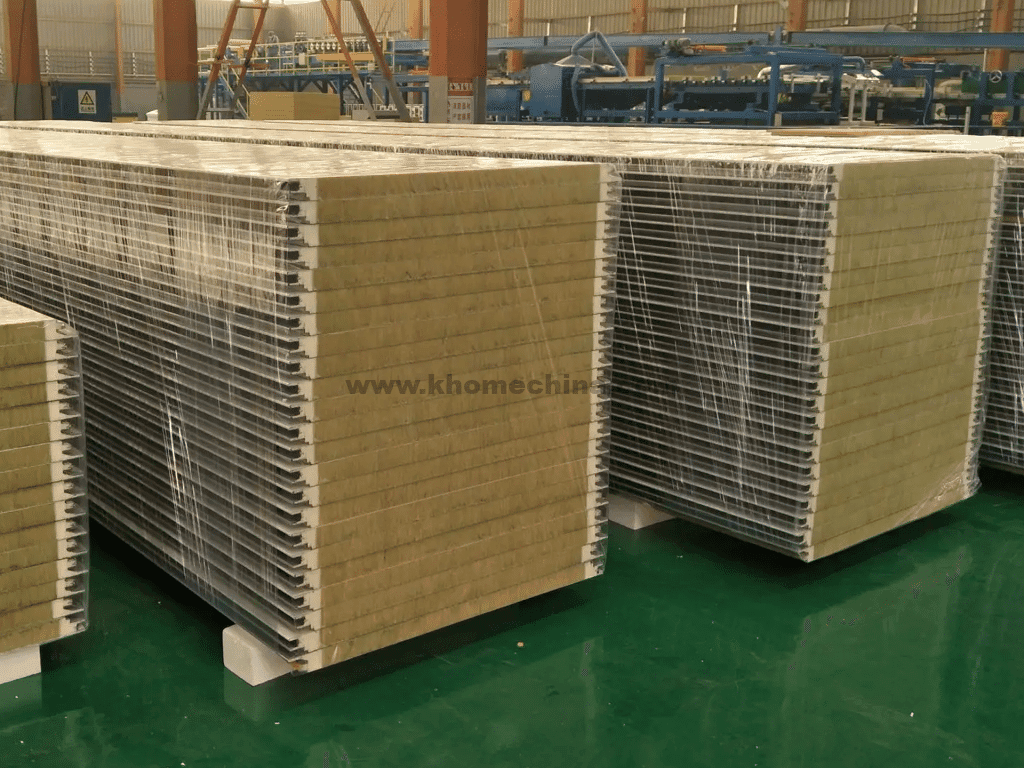

The walls of the whole container house are made of steel insulation sandwich panels, with galvanized steel plates on the inner and outer layers, and rock wool or other insulation materials in the middle. The insulation coefficient (U value) is as low as 0.28 W/m²K, with excellent thermal insulation performance. The doors and windows of the standard container are configured with steel fire doors and plastic steel sliding windows, which are both safe and practical.

Installation and expansion

All components of the flat-pack container use prefabricated holes and snap-on connectors, and only common tools (such as electric wrenches) are required for installation. At the same time, they support horizontal or vertical splicing of multiple containers to quickly expand space. This modular design increases installation efficiency by 70%, which is particularly suitable for emergency projects or remote areas.

Customize 20ft flat pack container house With these options

To meet the needs of different users, our 20-foot flat-pack containers provide full-process customization services. Customization options include core components such as frames, wall panels, customized patterns, steel frame colors, etc. This allows flat-pack containers to be flexibly adapted to diverse scenarios such as residential, commercial, and industrial.

Frame customization

We provide three frame structure solutions: basic, standard, and premium, covering the budget needs of users at multiple levels:

Flat Pack Container House basic Flat Pack Container house standard Flat Pack Container house premium

Sandwich wall panel customization

Wall panels are the core components that affect thermal insulation and fire protection performance. You can choose different insulation materials and safety levels according to environmental requirements. We provide the following options:

EPS Sandwich Panels rock wool sandwich panel PU Sandwich Panels PU Sealed Rock Wool Sandwich Panel PIR sandwich panel

customized patterns

The utilization of steel sandwich panels for wall construction brings forth a realm of design possibilities that seamlessly blend aesthetics with practicality. These panels possess the unique capability to replicate the visual essence of diverse materials, including wood, stone, brick, and other textures. This design flexibility is made achievable through the adaptable outer skin material of steel sandwich panels.

Color customization of steel frame

The standard color of flat pack containers is white, and there is no minimum order quantity limit. The purpose of choosing other colors is to match the commercial environment or enhance brand recognition. We provide color customization of the full RAL color range, but there will be a minimum order quantity requirement.

Selection Guide for Customized Flat Pack Containers

1、How to choose the level of steel frame?

The standard level of the flat pack container can meet most environmental requirements and ensure the house’s safety. If it is for short-term, temporary use, the basic level can meet the needs; if it is for long-term use or the environmental requirements are high (such as coastal areas, extreme climates), the premium level is more suitable. Although the initial price of the premium level is higher, its maintenance cost is low, and it is more cost-effective for long-term use.

2、Is there any additional cost for color customization?

Our standard frame color is white, but you can also choose a color from the RAL color card for customization. There is no additional charge for frame color customization. But if you need to customize the color or pattern of the sandwich wall panel, there will be additional costs according to specific needs.

3、What is the minimum order quantity?

Sandwich wall panel color or pattern customization: The minimum order quantity is 17 containers.

Adjustment of wall panel steel sheet thickness: The minimum order quantity is 5 sets of containers.

Multi-scenario configuration example for flat-pack containers

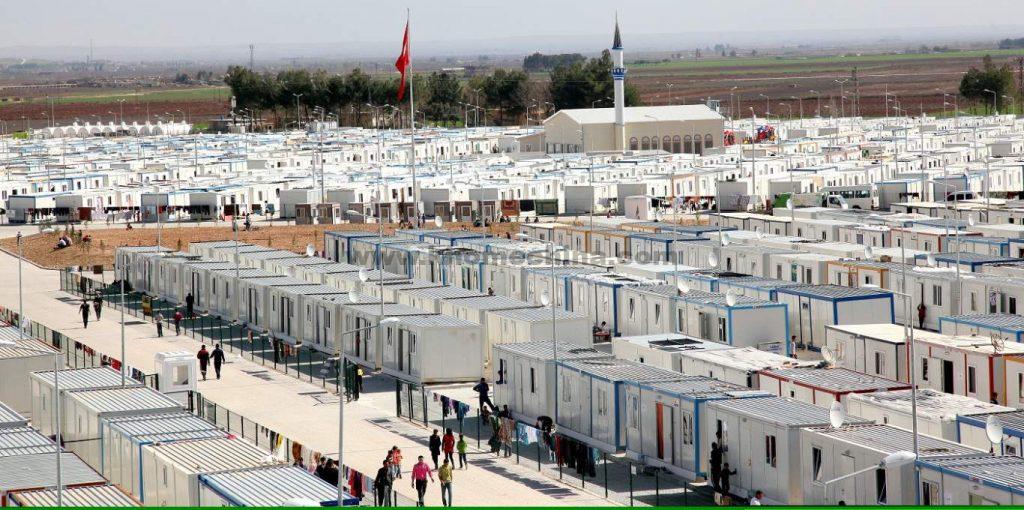

Container houses are widely used in construction sites, remote construction sites, post-disaster reconstruction and other scenarios due to their modular design and rapid deployment capabilities. They are often configured as functional spaces such as offices, dormitories, restaurants, and toilets to meet diverse needs.

On construction sites, 20-foot flat-pack container houses can be quickly built into temporary offices or workers’ dormitories. Equipped with bunk beds inside, it solves the problem of large-scale accommodation. In remote areas, container restaurants and kitchens provide workers with convenient dining space through a simple layout. In post-disaster reconstruction, modular medical stations or temporary housing can be deployed within 72 hours to meet emergency resettlement needs.

In addition, containers can also be used for equipment storage, mobile toilets, and other scenarios. Container houses have low foundation requirements and can adapt to extreme climates. With the advantages of rapid installation, flexible expansion, durability and environmental protection, they provide users with efficient and economical building solutions.

flat pack container meeting room flat pack container classroom

Khome’s flat-pack container prices | Container house factory

K-HOME’s flat-pack containers are based on flexible adaptation and efficient-cost performance, and build a price system around the actual needs of users. An empty flat pack container price ranges from $1500-2200 (basic~premium).

The standard 20-foot container, made with a galvanized steel frame and rock wool wall panels, can meet most temporary needs. For more complex environments, custom upgrades are available, and the budget will change based on the options chosen. No matter the size of the project, K-home provides detailed quotes.

If you already have a design, we will evaluate the cost based on materials, construction, and shipping. If you’re unsure about your needs, we can help by discussing factors like how long you’ll use it, what features you need, and the weather conditions. Contact K-Home anytime to get your quote.

⭐⭐⭐

basic

⭐⭐⭐⭐

standard

⭐⭐⭐⭐⭐

premium

How to transport and install a flat-pack container house?

- 01-Flat Pack Container House Unpack

- 02-Flat Pack Container House Column Installation

- 03-Flat Pack Container House Roof Installation

- 04-Flat Pack Container House Downpipes Installation

- 05-Flat Pack Container House Wall Installation

- 06-Flat Pack Container House Industrial Plug and Socket Installation

- 07-Flat Pack Container House Air Switch Installation

- 08-Flat Pack Container House PVC Trunking Installation

- 09-Flat Pack Container House Ceiling Installation

- 10-Flat Pack Container House Light Installation

- 11-Flat Pack Container House Skirting Line Installation

- 12-Flat Pack Container House Decorate

Sufficient stock to respond to customer needs | container houses from China

As a supplier of flat-pack containers, we always keep plenty of stock to meet your urgent needs quickly. We understand that customers around the world value fast delivery, so we use efficient inventory management and logistics to provide reliable supply chain support. Whether you need standard configurations or custom solutions, we offer flexible production services to ensure your project stays on schedule. No matter where you are, our professional service and ample inventory will provide you with seamless solutions.

K-HOME flat pack containers global application cases and customer review

Real project cases are the most pertinent review and reputation of K-HOME flat pack containers. Our flat pack containers have been exported to many countries around the world and have been successfully used in various scenarios, such as construction sites and remote areas. We have won high praise from customers for product quality and service. K-HOME always adheres to the concept of “customer first” and is committed to providing high-quality products and worry-free after-sales service.

Our flat pack containers are made of high-quality steel and precise production processes. This ensures that each product meets international standards. At the same time, they can maintain stable performance under extreme climatic conditions. In addition, from order consultation to after-sales support, the K-HOME team can respond quickly and provide you with customized solutions. If you are looking for a flat-pack container supplier, K-HOME will be your trusted partner.

Need help finding the right prefabricated container house?

Take to consider when ordering a container house

1、Clear requirements: First, you should know what your project requires. This includes the size, purpose, quantity, function, cost, installation, and where the container house will be used. Knowing your needs helps you choose the right product.

2、Suppliers: Choose reliable suppliers to ensure you get good quality and after-sales service. If you have time, it is best to visit the factory. K-HOME welcomes visits at any time.

3、Price: When buying a container house, price is important, but it is not the only thing to consider. You should also consider quality and after-sales service to get the best value for money.

4、Delivery time: When buying a container house, always check the delivery time to ensure it arrives on time. In addition, understand the supplier’s production capacity and delivery schedule to avoid delays that may affect your project.

Comparison of different types of container houses

- 1、Standard price:detachable containers > flat pack containers > folding container house

- 2、Customizability: detachable containers > flat pack containers > folding container house

- 3、Installation speed: folding container house > flat pack containers > detachable containers

- 4、Shipping Capacity:detachable containers > flat pack containers > folding container house

detachable container house

Folding flat pack container

SEND A MESSAGE