PEB Building

pre-engineered building / peb pre engineered building / peb steel sturcture / peb building manufacturer / Peb Manufacturer

PEB building, also referred to as pre-engineered building, PEB pre-engineered building, Prefabricated steel structures building, are a contemporary building technique. Columns and beams, among other architectural components, are prefabricated at a factory and subsequently installed on-site. By using readily assembleable standard forms, engineers are able to create PEB structures that are both robust and economical.

PEB building is quicker, less expensive, and more adaptable than reinforced concrete structures. PEB building is mostly composed of steel, which is strong and adaptable and may be used in a variety of settings, including workshops, warehouses, sports facilities and so on.

China PEB Building Manufacturer | Your Trusted Partner

Henan K-home Steel Structure Co., Ltd. mainly deals in steel structures and prefabricated houses. It is a production enterprise integrating product research and development, design, production, and sales. K-HOME’s production workshop covers an area of more than 20,000 square meters and has 6 steel structure engineering designers. At the same time, we have 9 complete production lines, 120 production technicians, an average annual output of 20,000 tons, and an average annual growth rate of 30%.

Steel Structure Building Fabricator | K-HOME

Project cases of K-HOME steel structure construction

As a Steel structure experts, K-HOME builds quality steel buildings for all industrial and commercial needs.We are a trusted partner for steel warehouses, steel workshops and custom building solutions. K-HOME has obtained ISO9000 certification and CE certification, and its products are exported to more than 100 countries including Africa, Asia, and South America.

prefabricated warehouse building in Mozambique Pre-Fabricated Warehouse in Saint Vincent peb building for Fertilizer Plant in China

PEB Building Components

PEB steel structure is mainly composed of steel beams, steel columns and other components made of steel and steel plates. The components or parts are usually connected by welds, bolts or rivets. Because of its light weight and simple construction, it is widely used in industrial plants and warehouses, multi-storey commercial buildings, agricultural breeding and other fields.

Primary Members of PEB building

1. Beams: Beams are horizontal load-bearing components in steel structures. They mainly bear the loads from floor slabs, roofs and other components, and transfer these loads to columns. Common beams include I-beams, box beams, etc.

2. Columns: Columns are vertical load-bearing components in steel structures. They mainly bear the loads from beams, roof trusses and other components, and transfer the loads to the foundation. Common columns include H-shaped steel columns.

Secondary Members of PEB building

1. Purlins: Purlins are components set on roof trusses or roof beams to support roofs and wall panels. They are usually made of cold-formed steel, such as Z-shaped or C-shaped purlins. Purlins mainly bear the loads of roofs and wall panels, and transfer the loads to steel columns or roof beams.

2. Girts : Girts are similar to purlins but are used to connect columns in a building. These horizontal members support wall panels or columns, providing essential stability. They are installed by being fixed to the columns, which helps secure the wall materials in place. Girts are typically made from steel, making them strong and reliable.

3. Tie rods: Sag rods are vertical or diagonal tension members used in a roof structure. Their main purpose is to prevent the roof from sagging by providing tension support. Typically made from steel or high-strength alloys, sag rods help maintain the roof’s shape and stability.

4. Cross bracings: Cross bracings are diagonal members or wires found in a structure. Their main purpose is to provide stability and help resist lateral forces, such as wind or earthquakes. Usually made from steel , cross bracings play a crucial role in keeping the building strong and secure.

Roof Panels and Wall Panels

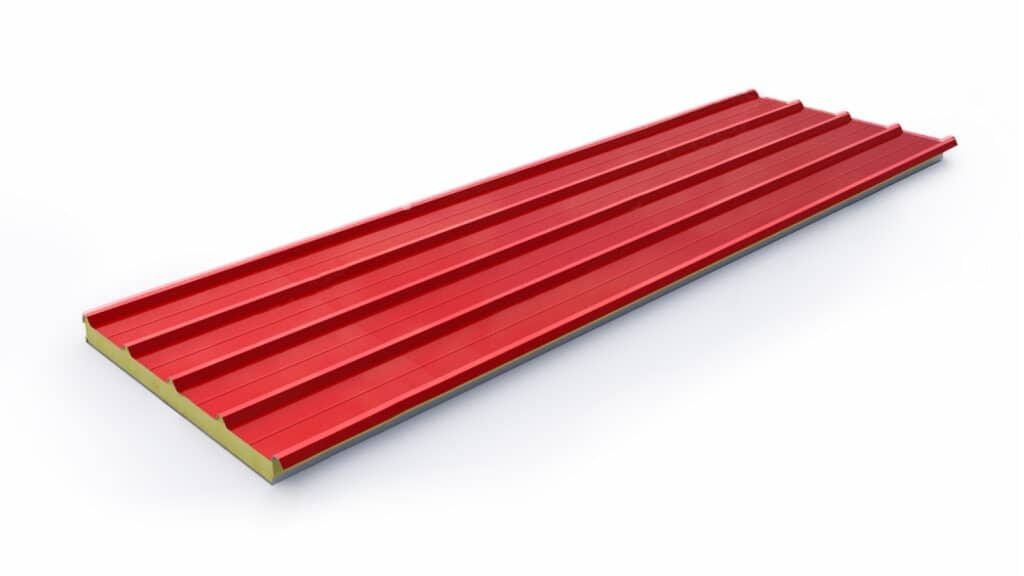

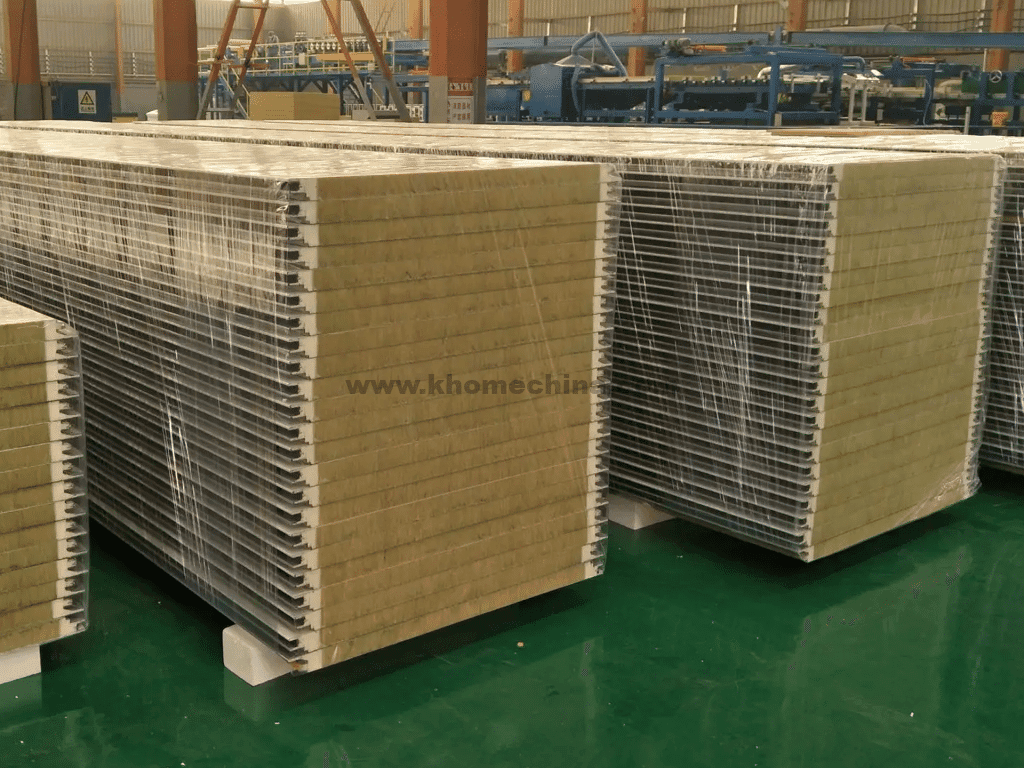

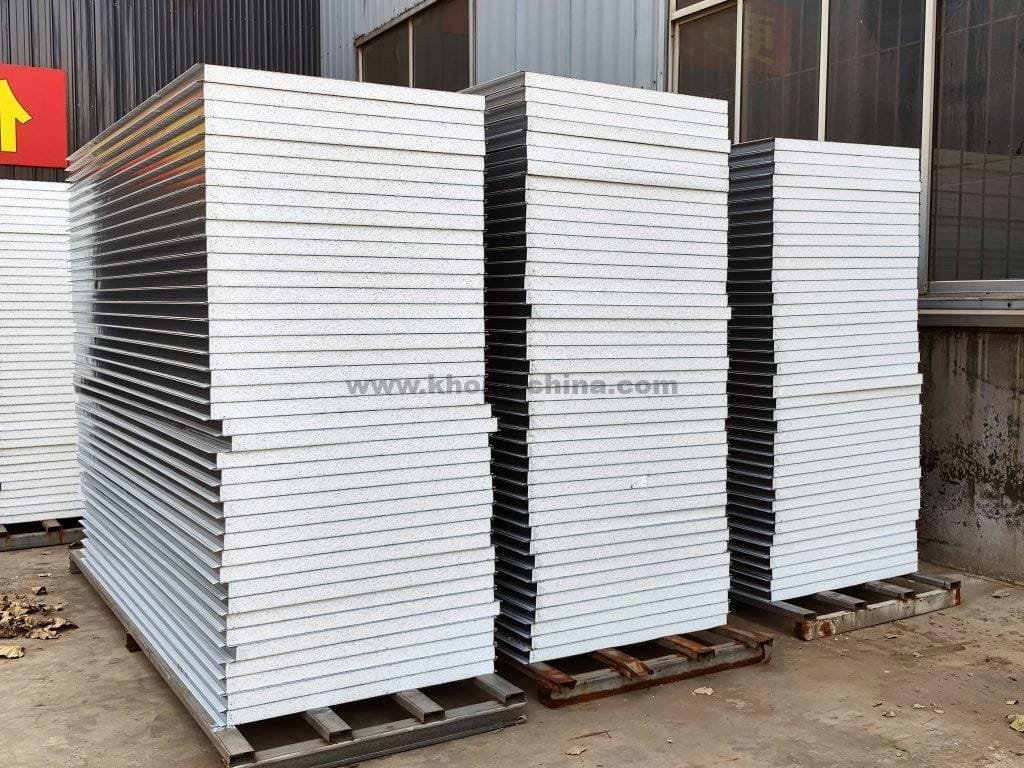

5. Roof panels and wall panels are components covering the roof and walls, and they mainly play the role of enclosure and thermal insulation. Common roof panels and wall panels include metal panels, composite panels, etc. Choose the appropriate material and thickness according to different building requirements.

- metal cladding panel

- sandwich roof panel

Enclosure structure built with color steel plates

The Types of PEB steel frame structure

- Clear Span: Clear span PEB buildings have no interior columns, providing a large, open space. This type is ideal for factories, warehouses, and event spaces where unobstructed floor area is required.

- Single slope: Single-slope PEB buildings are characterized by a roof that slopes in one direction. They are often used for agricultural buildings, sheds, and small – scale industrial facilities.

- Multi-Span: There are different types of multi – span PEB buildings. They can be designed to have multiple bays, providing more space and flexibility. These are suitable for large – scale industries and warehouses.

- Multi-gable: PEB buildings have multiple gable roofs, which can add aesthetic appeal and provide additional ventilation. They are often used in commercial and institutional buildings.

Clear Span Single slope Multi-Span Multi-gable Clear span with crane Multi-span with crane

- Clear span with crane: For industries that require heavy – lifting equipment, clear – span PEB buildings with cranes can be designed. These buildings are equipped with overhead cranes, allowing for efficient material handling.

- Multi-span with crane: This type of PEB building combines the features of multi – span construction, cranes, and mezzanines. It is suitable for large – scale industrial operations that need both storage space and heavy – lifting capabilities.

PEB Building Design

PEB building have a very adaptable design. The size, form, and arrangement of the structure can be changed by engineers to accommodate the intended function. For instance, a warehouse would need certain storage designs, but a factory might need a sizable open-plan area. The building can survive a range of weather circumstances because to exact predictions of loads, wind resistance, and seismic forces made possible by advanced design software. Additionally, the design may be readily expanded or changed in the future thanks to the utilization of pre-engineered components.

At K-HOME, we provide tailor-made PEB building design services. Our services run throughout the entire sales process. In addition, we provide after-sales support to help you solve any problems encountered during the installation process.

PEB Building Cost

The cost of a Industrial peb building is directly related to its span, height, and usage:

(1) For a PEB building with a height of no more than 8m, a span of no more than 30m, equipped with a 5 – ton crane, and with insulated external enclosures, the cost per square meter is about $80 – $90. If there is no crane, the cost will drop to about $70 – $80 per square meter.If your steel structure building does not require insulation, the price will drop to about $50-$60 per square meter.

(2) By referring to the above situation, as the height decreases, the cost will also decrease. The impact of span changes on the cost can be divided into several cases: For factory buildings with a span over 15m, starting from 15m, as the span increases, the cost per unit area will decrease. However, starting from 15m, as the span decreases, the cost per unit area will increase. This is for factory buildings with cranes. For factory buildings without cranes, the situation is the opposite. So, the specific cost depends on the usage of the factory building and the height – to – span ratio.

Normally, the cost of a single – story steel – structure factory building ranges from $50 to $100 per square meter. The price range is quite large, and the specific cost is related to the design scheme and technical requirements. Meanwhile, the cost will also fluctuate according to the local labor cost.

Applications of PEB Building

Industries

PEB buildings are widely used in various industries. Factories benefit from the large open spaces and customizable designs. Warehouses can take advantage of the efficient storage solutions and quick construction time. Workshops require a sturdy and functional environment, which PEB buildings can provide. Cold storage facilities need excellent insulation, and PEBs can be designed to meet these requirements.

Heavy Industries

In heavy industries such as cement steel plants, steel plants, sugar mills, and ceramic factories, PEB buildings offer the strength and durability needed to withstand harsh operating conditions. They can be designed to support heavy machinery and equipment.

Government Buildings

Aircraft hangars are an important application of PEB buildings in the government sector. These buildings need to be large, strong, and able to protect aircraft from the elements.

Agriculture

In the agricultural sector, PEB buildings are used for poultry or dairy farms and bulk product storages. They can provide a clean and controlled environment for livestock and protect agricultural products from the weather.

PEB Building Construction

The construction process of PEB buildings is relatively straightforward. First, the pre – fabricated components are transported to the construction site. Then, the foundation is prepared, and the steel frames are erected. Next, the roof and wall panels are installed, followed by the doors, windows, and other finishing touches. The construction time is significantly shorter compared to traditional buildings, allowing clients to start using their facilities sooner.

Frequently Asked Questions

SEND A MESSAGE