flat pack modular buildings

k-hOME is a prefab container manufacturer, providing flat pack modular building solutions – reliable, customizable, Multi-scenario use

flat pack container house / flat pack containers / flat pack container building / flat pack office container

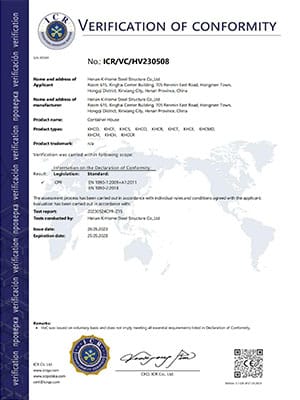

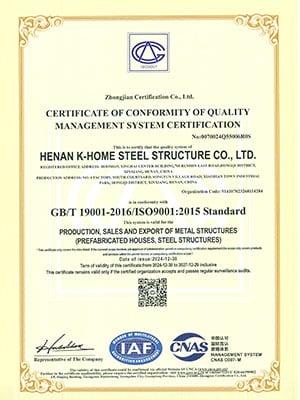

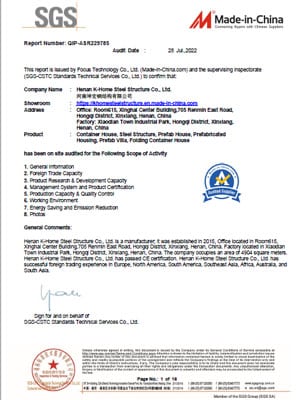

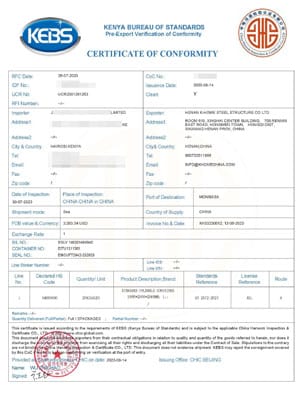

Certifications & Standards

We uphold the highest standards. Behind every building is a rigorous commitment to safety, quality, and sustainability, backed by dozens of internationally recognized certifications.

flat pack modular container building

Flat pack modular buildings are prefabricated container structures that are easy to assemble, transport, install, and disassemble. Designed as stackable modular units, they can create up to three stories of living and usage space.

K-HOME’s flat-pack buildings offer the perfect portable solution. They can be flexibly deployed in a variety of locations. Flat pack modular buidlings are ideal for construction sites, office and living containers, workforce campsite, school/college classrooms, temporary housing and storage, and construction site accommodation.

The interior layout of a flat pack container can be flexibly customized to suit user preferences. We also offer a comprehensive selection of accessories, including furniture, appliances, and bathroom fixtures, to streamline your procurement process. Furthermore, the electrical system can be customized to local standards, currently supporting various circuit specifications, including Australian and German standards, ensuring global compatibility and safety.

Structure of modular flat pack containers

If you disassemble a standard packing container, you can divide it into four core components: top cover, bottom plate, support structure, and enclosure structure. Each component has been precisely designed and industrially produced to ensure structural stability and functional practicality. The following is a detailed disassembly analysis:

Roof structure

The roof is usually made of galvanized steel sheets pressed into corrugated sheets with rock wool insulation embedded inside. From bottom to top, they are galvanized ceiling steel sheets, roof main frame, 50mm thick insulation wool, and top galvanized roof panels. The roof beams are designed with drainage grooves around them, and rainwater can flow out along the drainage grooves to prevent accumulation on the roof. This design not only has excellent waterproof performance, but also can effectively keep warm and insulate.

- flat pack container-ceiling

- flat pack container-roof frame

- flat pack container-PE film

- flat pack container-insulate rock wool

- flat pack container-roof structure

floor structure

The floor system is made of cold-bent galvanized steel beams and has a #-shaped main frame, with a maximum load-bearing capacity of more than 30 tons (standard payload is about 30 tons). The ground is paved with 18mm thick high-density cement board, and the surface is covered with PVC floor leather. They can effectively block moisture penetration and ensure that the ground is dry and durable.

- flat pack container-floor frame

- flat pack container-18mm cement board

- flat pack container-PVC floor leather

Support structure

Galvanized steel columns are set at the four corners of the container. They are connected to the integral roof and the floor through high-strength bolts to form the overall frame of the container house. At the same time, drainage pipes are set in the surrounding steel columns to ensure that rainwater can flow smoothly to the ground to avoid water accumulation.

Enclosure structure (wall panels, doors, windows)

The walls of the whole container house are made of steel insulation sandwich panels, with galvanized steel plates on the inner and outer layers, and rock wool or other insulation materials in the middle. The insulation coefficient (U value) is as low as 0.28 W/m²K,excellent performance. Doors and windows are equipped with steel fire-rated doors and plastic-steel sliding windows.

Installation and expansion

All components of the flat-pack container use prefabricated holes and snap-on connectors, and only common tools (such as electric wrenches) are required for installation. At the same time, they support horizontal or vertical splicing of multiple containers to quickly expand space. This modular design increases installation efficiency by 70%, which is particularly suitable for emergency projects or remote areas.

modular flat pack building designs

The modular structure of the flat pack cabin offers a high degree of flexibility. These flat pack containers can be designed as standalone units to meet standardized accommodation requirements, or they can be combined to create a more spacious, complex space with differentiated interior areas designed according to specific functions.

Whether rapidly replicating a single unit or reconfiguring multiple functions, this adaptability, rooted in its modular core, enables the flat pack building to precisely respond to diverse scenarios and needs.

flat pack cabin unit designs

flat pack modular building design

Flat pack container buildings can be designed in various heights and styles, depending on your preferences and the amount of land available. A one-story structure generally doesn’t require many additional components, but it does take up more land. If land is scarce, a multi-story structure can be constructed.

Furthermore, modular flat-pack buildings can be customized, with a comprehensive selection of RAL colors and additional customization options such as added cladding panels.

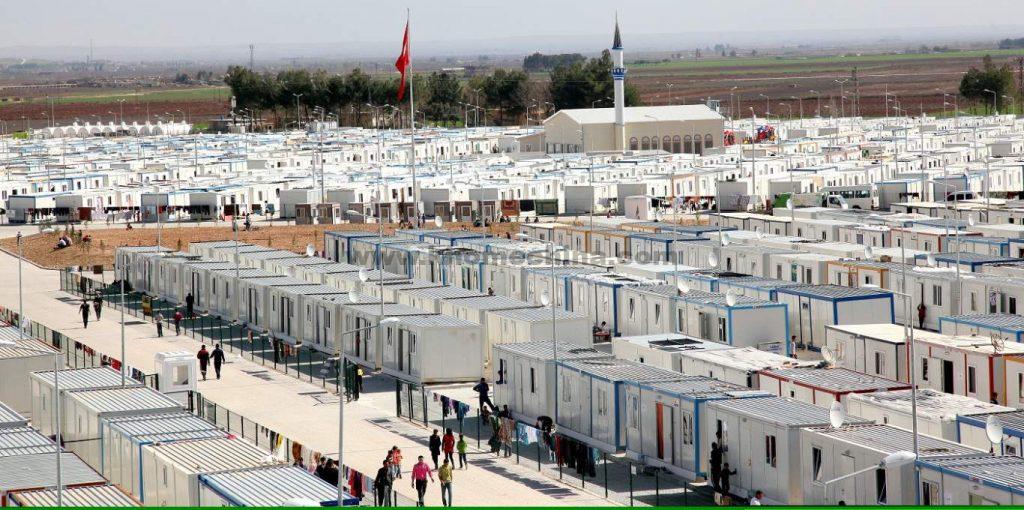

flat pack Modular building usage reference

Flat-pack modular buildings are widely used, often found on construction sites, remote mining and oil camps, emergency response sites, and temporary events. They can serve as on-site offices, staff dormitories, locker rooms, dining areas, storage spaces, and sanitary facilities. Our flat-pack modular containers are easy to assemble and quick to set up, providing an ideal prefabricated, portable solution for a variety of needs.

modular office building

Flat-pack offices offer highly flexible space solutions tailored to diverse office needs. These modular structures allow for precise planning based on team composition. They can be flexibly configured as open work areas, independent work blocks, or customized functional spaces to meet diverse office needs, achieving efficient space utilization and a comfortable experience. Modular office buildings can also be easily configured or expanded with meeting rooms, changing rooms, toilets, etc.

modular accommodation building

site accommodation is one of the most common applications of flat-pack modular building. Each standard unit can be flexibly configured with four single beds or bunk beds, accommodating up to 8 people. This highly standardized design allows for rapid, mass deployment of units, making it easy to replicate and expand large-scale camps.

For interior planning, we offer two practical options: providing each unit with its own private bathroom, maximizing employee privacy and convenience; or adopting a shared bathroom area for greater cost-efficiency and space utilization.

modular school building

Modular flat pack building offers the perfect solution for unexpected educational space needs. Whether rapidly adding temporary dormitories to accommodate enrollment expansion or urgently expanding classrooms and training spaces, we offer construction speeds far exceeding those of traditional construction methods and exceptional cost-effectiveness, ensuring your educational activities are not limited by space.

flat pack modular construction | Quick and Easy to assemble modular flat-pack container

Flat-pack modular buildings are easy to construct. Typically, they simply need to be placed on flat land. However, we offer a variety of foundation construction methods to meet unique requirements, depending on the geological conditions of each region. Furthermore, for coastal areas susceptible to hurricanes, we offer a variety of reinforcement solutions to ensure building stability and safety.

At K-HOME, our commitment goes beyond high-quality products; we also provide comprehensive lifecycle support. After the product is delivered to the project site, we provide detailed installation drawings and videos. If these are not enough to resolve your installation issues, we also provide on-site technical support until your flat pack building is successfully established.

- 01-Flat Pack Container House Unpack

- 02-Flat Pack Container House Column Installation

- 03-Flat Pack Container House Roof Installation

- 04-Flat Pack Container House Downpipes Installation

- 05-Flat Pack Container House Wall Installation

- 06-Flat Pack Container House Industrial Plug and Socket Installation

- 07-Flat Pack Container House Air Switch Installation

- 08-Flat Pack Container House PVC Trunking Installation

- 09-Flat Pack Container House Ceiling Installation

- 10-Flat Pack Container House Light Installation

- 11-Flat Pack Container House Skirting Line Installation

- 12-Flat Pack Container House Decorate

project display

Real project cases are the most pertinent review and reputation of the K-HOME flat pack modular building. Our flat pack containers have been exported to many countries around the world and have been successfully used in various scenarios, such as construction sites and remote areas. We have won high praise from customers for product quality and service. K-HOME always adheres to the concept of “customer first” and is committed to providing high-quality products and worry-free after-sales service.

SEND A MESSAGE