steel crane buildings

steel crane structure / Steel Structure With Crane / overhead crane steel structure / Crane Supporting Steel Structures

In industrial manufacturing, distribution centers, and warehousing, steel crane buildings have become essential infrastructure. They offer high space utilization and heavy-load capacity to maximize production efficiency.

As China’s few integrated manufacturers in crane R&D and steel structure fabrication, K-HOME focuses on providing integrated solutions for cranes and steel structure buildings. We overcome the traditional limitations of “equipment-building separation design”. Through the integrated design of cranes and steel structures, we provide safe, reliable and cost-effective industrial building systems around the world.

Whether you need a small assembly workshop with a 5-ton overhead crane or a large manufacturing facility supporting a 50-ton double-girder crane. K-HOME provides end-to-end technical solutions—from design to production. Our expert team tailors optimized solutions to your specific needs.

Submit your project requirements today, and our engineers will provide one-on-one professional support!

What are steel crane buildings?

Steel Crane Buildings are industrial steel buildings with high-strength steel framing as the main body and integrated overhead crane systems. Unlike traditional factories that install cranes after construction, these crane systems are designed to work with steel structures from the beginning.

Steel crane buildings are a building structure specially designed to support and operate the crane. It is usually composed of crane supporting steel structure and crane system.

The steel structure uses high-grade materials (like Q355B steel) to form the building’s framework – including steel columns, beams, trusses, and specially designed crane runway beams. These components are connected through welding or bolting to create an extremely sturdy frame capable of handling both the crane’s weight and dynamic lifting loads. With carefully calculated spans (typically 30-60 meters) and heights, these buildings maximize workspace efficiency by minimizing column obstructions while providing optimal crane coverage.

The overhead crane system (typically European-style overhead cranes) actually uses the building’s structure as its support system. The crane runs along runway beams installed on the steel framework, moving horizontally and vertically within its designated coverage area. This design allows full utilization of the workspace below the crane bridge without interference from ground equipment.

Thanks to their exceptional strength and stability, Steel Crane Buildings are widely used in factories, workshops, warehouses, and logistics centers. They’re engineered to not only support the crane’s weight and operational loads but also withstand external forces like wind and seismic activity – ensuring long-term structural integrity and safety.

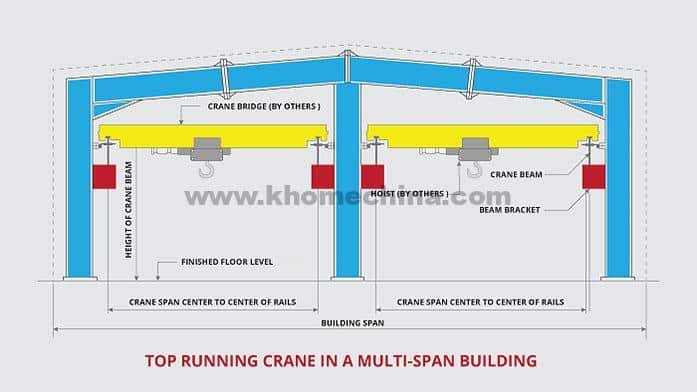

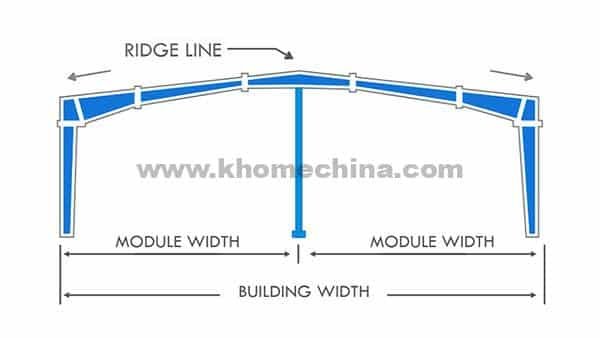

steel structure type: double-slope single Span

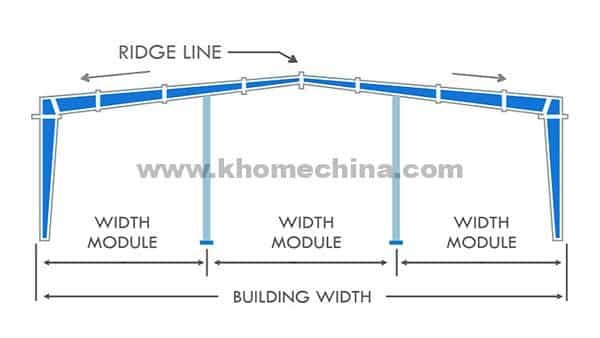

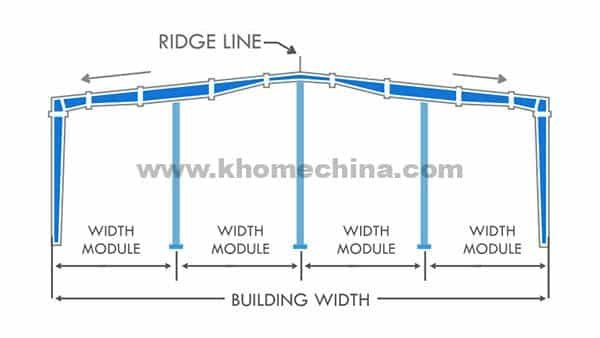

crane system: Bridge overhead cranesteel structure type: double-slope double-span

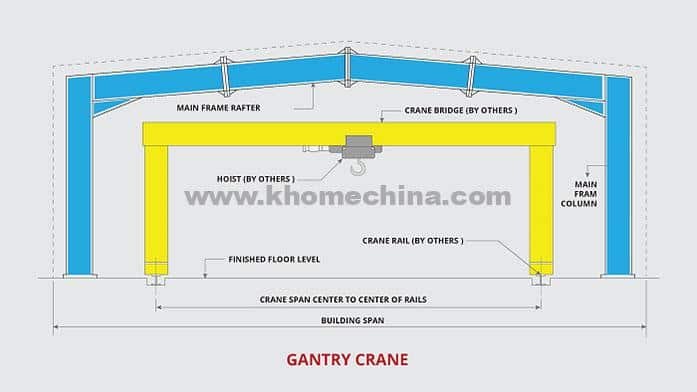

crane system: Bridge overhead cranesteel structure type: double-slope single Span

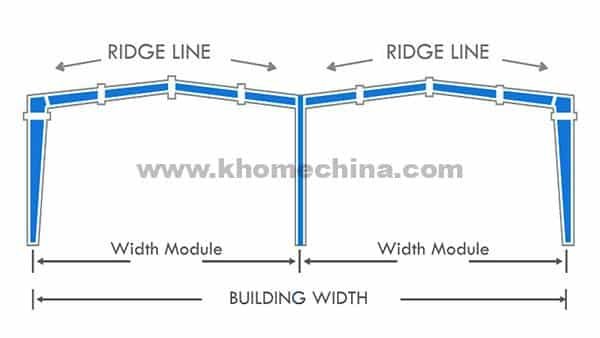

crane system: Gantry crane

- Industrial Steel Crane Buildings

- Steel Workshop Building With Crane

Crane Supporting Steel Structures – portal steel structure

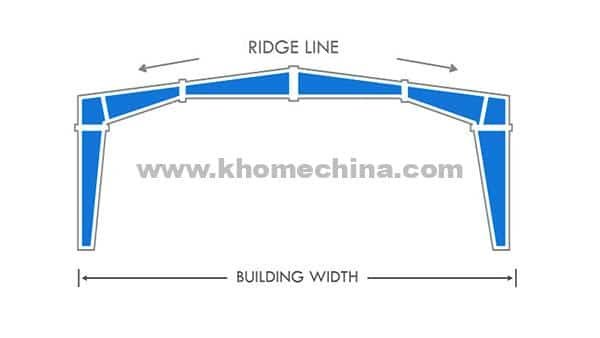

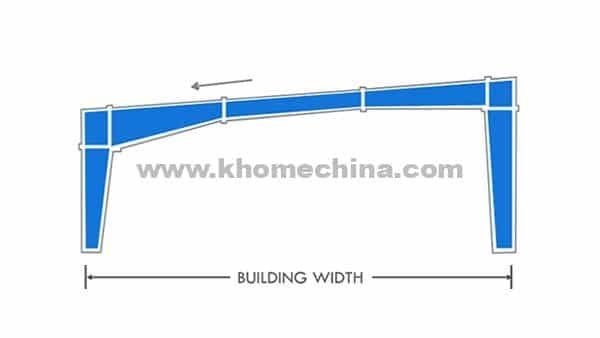

In the construction of crane steel buildings, portal steel structures are our primary structural solution. The portal steel structure consists of steel columns, steel beams and support systems, forming a shape similar to a “gantry”, and the top main beam supports the running track of the crane.

The portal steel structure can be designed as single-span, double-span, multi-span and other forms according to actual needs. These structures can adapt to different span requirements and crane load requirements. Our professional team carefully considers building width, height, Crane operating level and operating frequency and local dynamic loads (including wind and snow loads) to recommend the most suitable portal frame type. At the same time, we will use the optimized steel section that has been accurately calculated, and pay special attention to the uniformity design of the column section to ensure the overall stability of the crane during operation. At the same time, we employ precisely calculated, optimized steel sections with particular attention to uniform column cross-sections, ensuring overall stability during crane operation.

As a professional steel crane buildings supplier, K-HOME provides integrated design solutions combining steel structures with crane systems.These designs ensure the compatibility of the entire building system, avoid problems such as difficult installation of the crane, structural instability, operation restrictions and safety hazards, and create a safe and efficient working space for your industrial workshop.

Double-slope single span single-slope single span Double-slope double span Double-slope multi span Double-slope multi span Multi-slope double span

Overhead Bridge Crane Systems in the Steel Crane Building

An overhead crane is a lifting equipment installed horizontally above a workshop or warehouse for lifting materials. The bridge of the overhead crane runs longitudinally along the tracks laid on the elevated platforms on both sides. They make full use of the space under the bridge to lift materials without being hindered by ground equipment. Overhead cranes are one of the most commonly used material handling equipment and are also the most widely used and largest type of lifting machinery.

Common types of overhead cranes used in steel structure workshops include:

Single-girder overhead bridge crane: This crane consists of a single beam and an electric hoist. The main beam structure uses I-beam or box beams, and the end beams connect the main beams and support the running mechanism. The electric hoist is installed under the main beam as a lifting device. The rated lifting capacity of a single-beam bridge crane is usually between 1-20 tons, and the working level is generally A1-A3. Its span range can reach 5-35 meters (the span of the crane is not equal to the span of the steel structure). The single-beam bridge crane has a simple structure and low maintenance cost, and is suitable for small and medium-sized machine processing workshops, warehousing and logistics centers, etc.

Double-girder overhead bridge crane: This crane consists of two main beams across the plant and an electric hoist. The double-beam design provides higher strength and stability. The double-beam bridge crane has a wide range of lifting weights, a span of up to 50 meters, and a working level of A3-A6. This crane runs more smoothly and has more precise positioning. It is suitable for heavy machinery manufacturing, steel and metallurgical industries, large equipment installation, etc.

K-HOME is a professional supplier of Crane Steel Structures. We provide a high-quality steel structure workshop and crane equipment. Our team of engineers will customize the crane system according to the actual span, column spacing, and bracket height of the workshop. And integrate the track installation plan into the building drawings in advance to achieve precise matching of the track and the steel structure support system. Ensure that your steel structure crane building can operate smoothly.

Key considerations for integrated design of crane systems and steel structure buildings

When constructing a steel building with an overhead crane, the crane equipment requirements and the building structure must be considered in tandem, rather than separately. It is important to define the requirements for constructing this steel building. This includes: the lifting capacity of the crane, the lifting height, the span, the expected hours of use per day and the purpose of the building. These basic data will have a direct impact on the selection of the crane and the strength design of the steel structure.

1、Crane lifting capacity: The lifting capacity of a crane is the maximum weight that the crane can safely lift. For example, if a crane’s lifting capacity is labelled ‘10 tonnes’, it means that it can lift a maximum of 10 tonnes (including the weight of hooks, ropes and other lifting devices). This directly determines the strength of the steel ‘skeleton’.

It affects the design of the steel structure in terms of the thickness of the steel, the thickness of the steel column cross-section and the depth of the steel foundation. In other words, the design of a steel building needs to take into account the strength of the steel and the amount of steel used.

2、Lifting Height of Crane: The lift height of a crane refers to the vertical distance the crane hook rises from its lowest position (usually near the ground) to its highest position. Simply put, it is how high a crane can lift a load. Lifting height has an impact on the design of the steel structure:

- The clear height of the plant must match. Generally speaking, the height of a steel structure building (from the ground to the roof beam) must be greater than: hoist height + hook height + safety clearance. For example, if the crane lifting height is 10 metres and the hook height is 1 metre, then the clear height of the building must be at least 11.5 metres (10+1+0.5 safety clearance).

- Affect the steel columns and roof structure. The higher the lifting height → the longer the steel column → higher structural stability requirements

- Related to the span.

Overall, it directly affects the plant height, steel structure and overall cost.

3、span of the crane:The span of the crane refers to the horizontal distance between the crane rails, which is simply understood to be the working range that the crane can cover horizontally. Note: The span of the crane needs to be co-ordinated with the span of the building to ensure that the crane can be installed and operated smoothly. For example, if the crane has a span of 20 metres, the span of the building must be able to accommodate at least 20 metres, and often needs to be wider to allow for installation and operation. The span of the crane affects the design of the steel structure in the following ways:

- Influence the column span and the size of the main beams. The larger the span of the crane, the stronger the beams and columns are needed to support it. So when designing the steel structure, we should find the balance point and design the best solution.

- Impact on the runway beam support structure. Runway beams should be made of higher strength materials and reinforced.

- Combine the lifting capacity for linkage calculation. For the same lifting capacity and different spans, the type of steel used will be different.

Therefore, when designing the integration scheme of steel structure and tower crane, multiple factors should be considered at the same time. They are not a number, but a systematic project that affects the whole body.

At K-HOME, we do not recommend that your crane and steel structure design belong to different suppliers. You need a professional supplier to design both the building and the equipment. Only in this way can various compatibility issues be avoided during construction. We have encountered many cases where customers purchased the crane first and then designed the factory building. It turned out that the track installation position conflicted with the building columns, or the steel structure had insufficient bearing capacity and needed to be reworked and reinforced, which not only caused additional costs, but also seriously affected the project’s progress.

This is the value of K-HOME’s integrated solution. You just need to tell us your specific needs. Our professional team will take care of all the complex technical work: from calculating dynamic loads, to optimizing steel structure design, to ensuring the normal operation of the crane. Our goal is to provide you with the most economical and safest crane steel building solution.

Case study

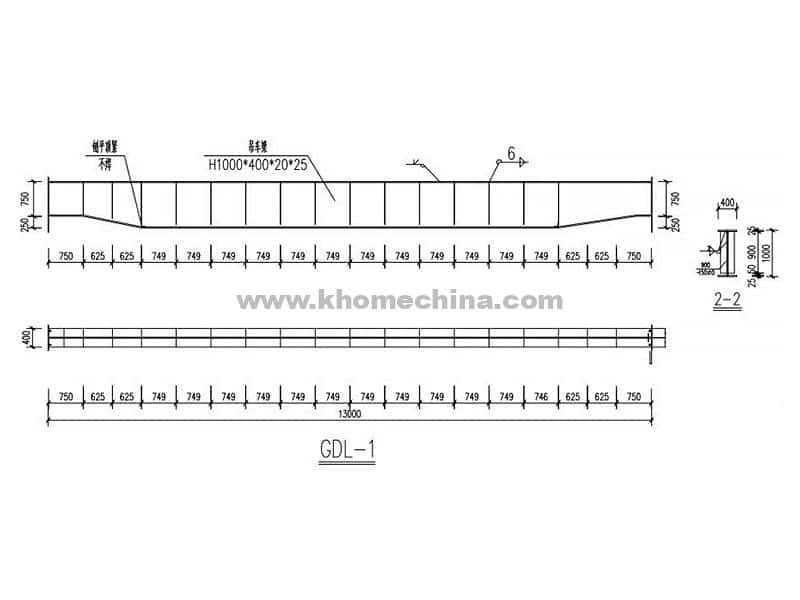

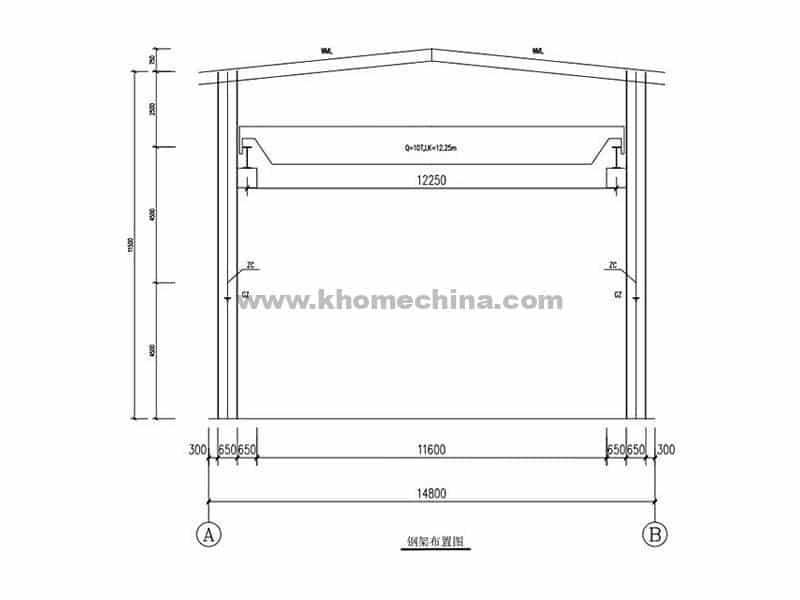

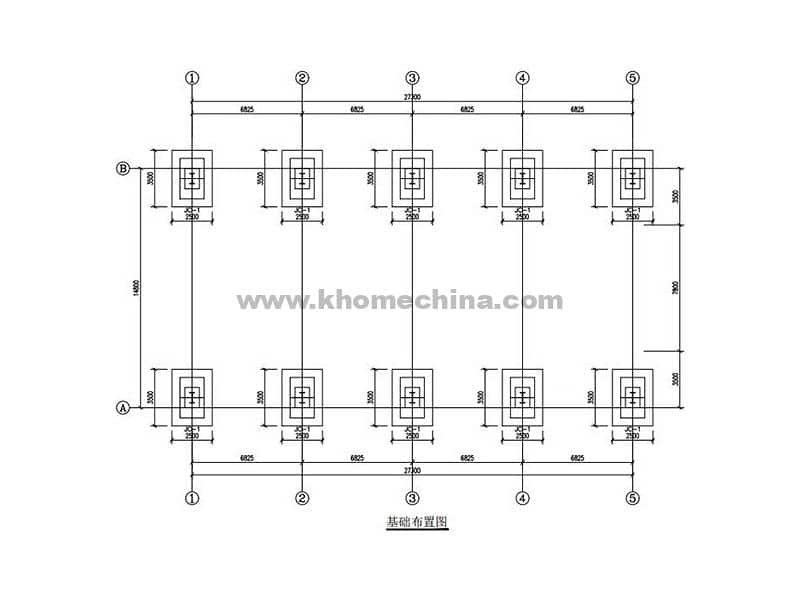

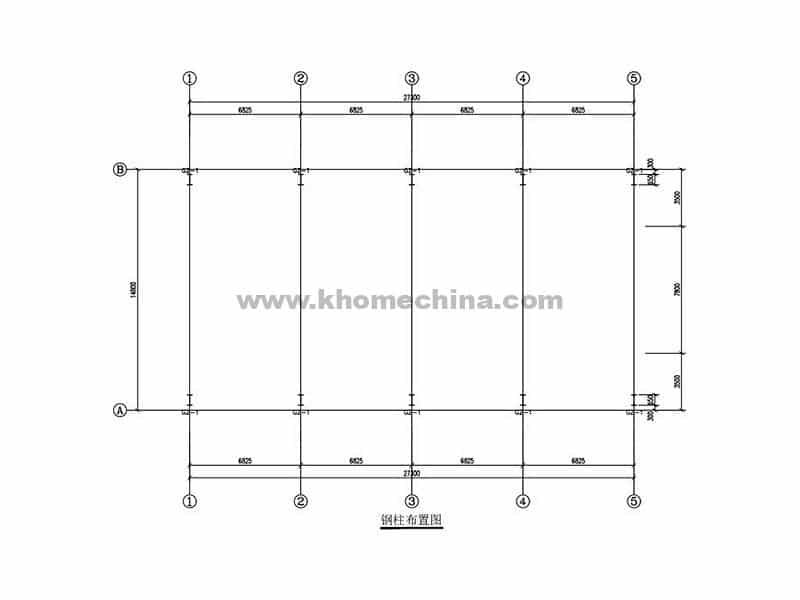

The project is 27.3 meters long, with a column distance of 6.8 meters, a width of 14.8, a cornice height of 11.5 meters, a corbel height of 9 meters from the ground, a maximum wheel load of 10T for the crane at full load, a crane span of 12.25 meters, an independent foundation, and rigidly connected column feet.

Roof and Wall Cladding System for steel crane building

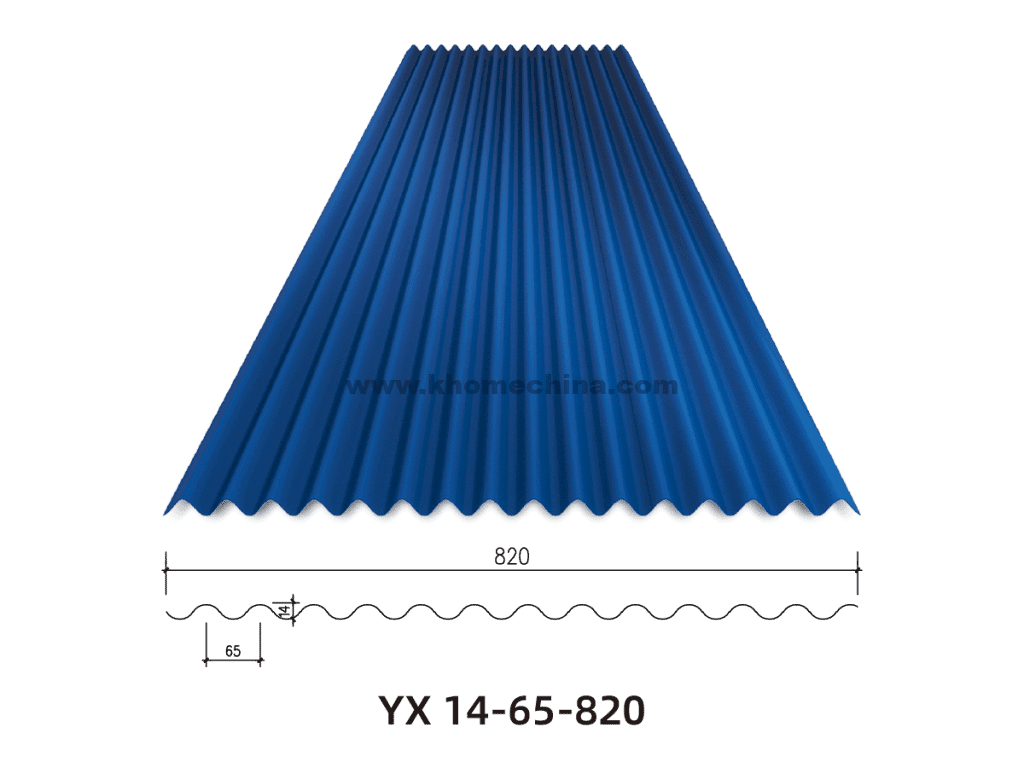

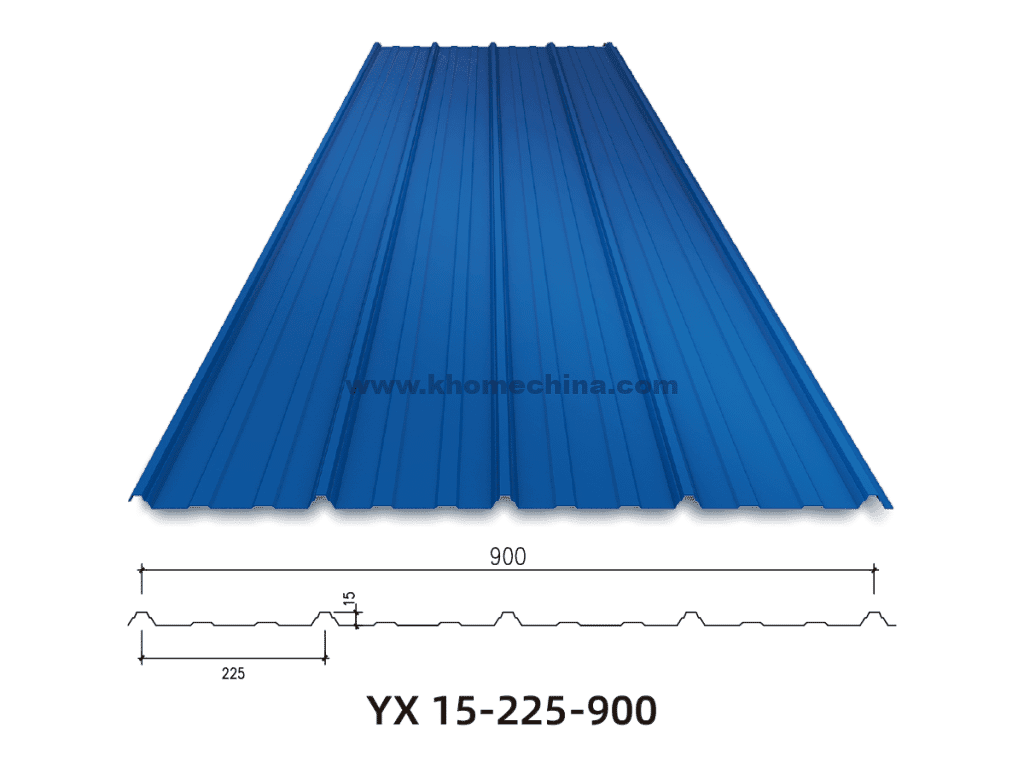

Usually, Usually, the enclosure system of steel buildings is economically feasible with metal cladding panels. K-HOME offers a wide range of modern profiles for all applications. These metal cladding panels are available in a variety of high-quality and aesthetically pleasing colors for roof and wall cladding. They have excellent corrosion and weather resistance, ensuring low maintenance costs and a long service life for the enclosure system.

RAL color system & Different appearances

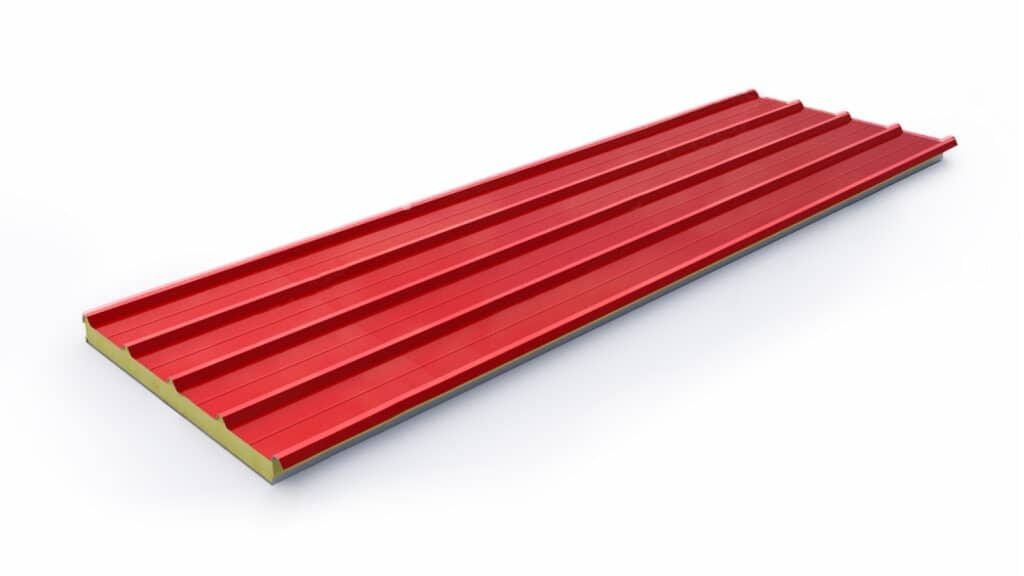

If your building is located in a hurricane-prone area or you have special requirements, we also offer sandwich panels with different insulation materials. These sandwich panels are made of different materials and specific weights to meet the requirements of different regional environments.

sandwich roof panel

sandwich roof panel

Sandwich Wall panel

Steel Crane Buildings Selection Guide

To help design the ideal steel structure workshop, please refer to the following guide:

Functional Requirements: Specify the purpose of the steel structure workshop, such as a production workshop, warehouse, etc.

Size Requirements:

① Length: Determine the total length of the workshop. Common column spacings are 6m, 7.5m, 9m, or 12m.

② Width: The width of the workshop is usually between 9m and 36m. For wider workshops, you need to specify the number of spans.

③ Height: Determine the clear height of the workshop, which is the height from the indoor floor to the intersection of the steel column axis and the steel beam axis. If there is no bridge crane in the workshop, it should be 4.5-9m; if there is a crane system, the specific model and lifting height of the bridge crane must be determined.

Roof Panels and Windows: Must meet specific requirements to ensure the integrity and functionality of the structure.

Special Conditions: Special areas must also consider geological and climatic conditions such as earthquake resistance level, local maximum wind speed, maximum rainfall and maximum snowfall.

If you have any questions, please feel free to contact us.

Why choose K-HOME steel crane buildings?

Choosing a professional steel crane building supplier can greatly simplify your workflow. As one of the professionalsteel crane building suppliers in China. We provide an integrated solution that integrates the design of steel structure and crane. Ensure that each link is seamlessly connected, avoid common coordination problems, and reduce risks in design and construction.

Our team has rich experience and expertise.They can provide you with the most optimized design solutions. These solutions ensure the strength and stability of the steel structure while meeting all technical requirements for crane operation. We use advanced design software and engineering analysis tools to ensure that every design detail is strictly verified while ensuring the economy and efficiency of the project.

Whether it is a new project or an upgrade of an existing facility, K-HOME can provide customized solutions to meet your specific needs. Contact us to ensure that your project is safe, efficient and economical.

SEND A MESSAGE