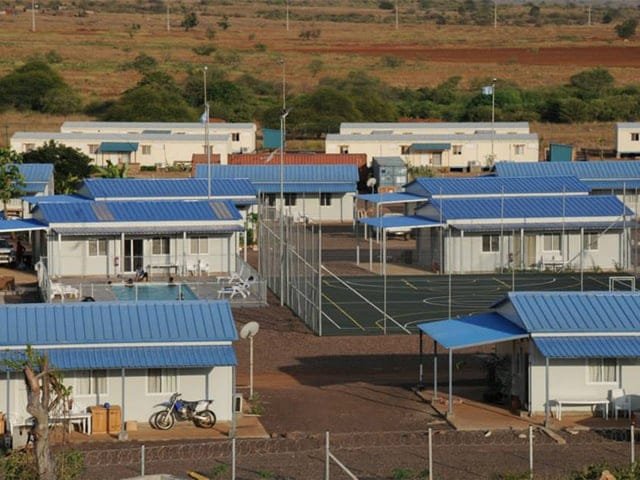

Camp Site Buildings Single Floor Prefab Home in Tanzania

Product: T-type Prefab House

Manufactured by: K-home

Purpose of Use: Staff Housing

Area: 1110 ㎡

Time: 2019

Location: Tanzania

Details

This Camp Site Buildings project in Tanzania was transacted in 2019. The client found us through made in china and found that our prefabricated buildings are easy to install, short construction period, cheap and comfortable. When the client expressed his needs, he was very excited, he said this is the product he was looking for, It seems that a new continent has been discovered.

Through communication, we learned that this client is one of the largest construction companies in Tanzania, headquartered in Tanzania. They specialize in construction companies for high-rise buildings, highways, dams and other engineering works across Tanzania. They are also responsible for many large infrastructure development projects, such as village electrification or irrigation system upgrades. The client’s request this time is mainly to build a worker’s housing for the natural gas processing plant under construction. But they didn’t have the blueprints, they only knew that they would build temporary dormitories for 80 workers and require two people each.

According to the customer’s needs, our designer drew the CAD floor plan for the customer, and after many times of communication and revision, the final draft was completed within 2 days. Of course, the customer is very satisfied with the drawings, but he thinks that our quotation has exceeded his budget, and he wants to control the budget cost as much as possible without reducing the quality of the product. The prefab house products we quoted for our customers belong to light steel buildings. The frame structure is very strong and durable, which can be disassembled and installed repeatedly and is resistant to corrosion. Its wall panels are made of 50mm thick rock wool sandwich wall panels, which have the characteristics of heat insulation and sound insulation. The overall service life of the prefab house is about 15 years.

Solutions

The client indicated that his project cycle is only 2 years, if the quality of the internal steel frame remains the same, whether it is possible to consider replacing the wall panels with cheap EPS foam sandwich wall panels. That way, when they move to the next site, they can reuse the steel frame and just replace the EPS siding. It sounds that like a good solution. But as we know, EPS foam sandwich wall panels are not fireproof and can only be used in outdoor temporary buildings. However, the customer’s construction site has more than 80 workers, and the use of EPS foam wall panels on the site will cause great safety hazards. Therefore, we denied the client’s idea and gave the client another solution.

First of all, with the consent of the client, we reworked the CAD layout and changed the two bedrooms to three bedrooms, and in order to ensure the comfort and activity space of workers, the designer changed each room area, from 18 square meters to 20 square meters. The layout of the laundry room, warehouse, and bathroom has also been adjusted. In this way, the layout is more reasonable, the building area and materials will be reduced a lot, and the total cost will be controlled.

Outcome

The client was very surprised when he heard about the new solution, he said it was a perfect solution, thank you for your efficient and professional service. Finally, after confirming the PI and the contract, the customer paid a 50% deposit first, and then we quickly arranged for the factory production, and the delivery was completed within two weeks.

About the installation problem:

Since the customer’s team has a certain construction and installation foundation, after receiving the goods, according to the installation instruction video and drawings we provided, the entire installation was completed within a week.

Project Gallery >>

The following is a picture of the completed site camp buildings project provided by the customer:

Cheap Prefab Camp Building Advantages

- Convenient transportation:all the conponents of prefab camp building are made in factory and lightweight is one of important characteristic of those material.

- Strong and durable:all structure is made of steel. It has good ability of anti-knock and resistance to deformation.

- Good sealing performance:strict manufacturing process make the trailer has very good water tightness

- Easy foundation: the prefab house based on concrete foundation,many combination space can be derived.Such as meeting room,dormitory, kitchen,toilet,etc.

- Convinient disassembly and assembly, Can be reused.

- Fast and easy toconstruction: a team can be installed more than 500 square metersa week

- Eco-friendly construction: not produce construction waste.

Projects Show

SEND A MESSAGE