Prefabricated flat pack container house

20ft flat pack container house / flat pack containers / flat pack container homes / insulated flat pack containers / flat pack storage containers

China Prefabricated Flat Pack Container House factory & Manufacturer | k-hOME

When purchasing flat pack containers, it is crucial to choose a high-quality supplier. As an industry-leading expert in flat pack container production, K-HOME provides customers with a full range of modular container solutions with its excellent product quality, efficient delivery capabilities and perfect service system. We are well aware that high-quality flat pack containers can not only extend the service life of the product, but also significantly reduce your maintenance costs. At the same time, the professional sales team will win your trust with sincere service, and the 7×24-hour after-sales support ensures that you can get technical guidance at any time during use.

K-HOME has a modern precision production line, and a strict quality control system ensures that every product meets the high standards of the industry. Adequate inventory enables us to respond quickly to customer needs and achieve efficient delivery. Over the years, our products have been exported to many countries around the world. Whether it is accommodation needs in remote areas, temporary educational facilities, or emergency medical facilities, K-HOME can provide customized planning solutions and reliable delivery services. With rich industry experience and unanimous recognition from customers, we are committed to creating the best quality flat pack container solutions for various application scenarios, so that you can have no worries every time you cooperate.

Contact us, inquire about our container house’s models and economic prices.

Flat pack container house for sale

What is a modular Flat Pack Container House?

The prefabricated flat-pack container house is a temporary building made by combining modular design with prefabricated production technology. Flat pack containers have the characteristics of high standardization, rapid assembly, flexibility, durability, easy disassembly, easy transportation and reuse. They are widely used in many places like construction camps, temporary accommodation, emergency rescue sites, field operations, exhibitions, commercial facilities, and cultural tourism. The flat pack container houses are designed to improve the comfort, safety and efficiency of temporary living or working conditions, while meeting the dual needs of environmental protection.

The prefabricated containers mainly consists of parts like a cold-bent galvanized steel frame, non-combustible insulation materials, prefabricated water and electricity systems, and interior decoration components. The steel frame structure ensures the overall strength and stability. The insulation materials provide good heat insulation, keeping the indoor environment pleasant. The prefabricated water and electricity system allows for plug-and-play use, greatly simplifying the on-site installation process and eliminating the need for complicated secondary construction. In addition, supporting facilities such as doors and windows, floors, ceilings, sanitary ware, kitchen equipment, etc. are also readily available and can be customized according to user needs.

Flat pack modular building is a sustainable building solution for expanding site camp, designed to be energy-efficient and flexible working spaces. The 20ft (6m) flat pack container house is the base model self-contained unit. We can fabricate a lot of units within 10 days and transport to your construction site. We can also come with a built-in kitchen, laundry, bathroom, and custom fold-down bed/lounge- All fittings meet your needs. Minimal onsite work costs mean you can move in the container buildings instantly without the disruptions of conventional building construction.

- insulated flat pack containers

- 20ft flat pack container house

- 6m flat pack containers

- 20ft flat pack containers

- flat pack containe office

- flat pack storage containers

- flat pack container homes

- customized flat pack container house

Technical Specifications of flat pack Containers for sale

We sell standard flat pack containers, their dimensions are 5900mm* L2438mm *W2896mm H, of course, these flat pack containers can be customized or tailored according to your requirements. Please see the standard specifications of standard containers below:

| Structures | Parameter |

|---|---|

| Roof System | |

| Steel frame | The steel frame is Q235 galvanized fitting; |

| Roof insulation | The ceiling is blue color steel pre-coated 0.4mm outside strong steel sheet; |

| With 50mm glass wool insulation material; | |

| Roof ceiling | The ceiling is shaped steel plate with different pattern |

| Floor System | |

| Steel frame | 3mm Galvanized Steel for main structure + 1.5mm square tube for the secondary beam |

| Floor | 15mm chipboard + PVC leather floor |

| Column System | |

| Column | 2.5mm Shaped Galvanized Steel |

| Wall System | |

| Wall Panel | Material: Rock Wool/PU/PIR Sandwich Panel ; Thickness:50mm/75mm/100mm |

| The outside color is light silver-gray (0.35mm thickness steel ); Inside is white color steel (0.35mm thickness steel ). | |

| Door & Window System | |

| One Door | Material: Steel Door;Size:2000*980mm(H*W) |

| Two Windows | Material: Aluminum Size:1200*1000mm(H*W);alloy steel double hollow glass sliding window (including screens) |

| Electric System | Includes: one ordinary LED light, A-SW double sockets 2set, A-SW air-switch 2 set, |

| Electrical box with safety protection device connecting cable for connecting; | |

| Accessories | Electric wire; Sealant; Wiring tube; Screws and other accessories. |

20ft flat pack Container house with customized options

1. Be Sure The Size Of the Container Unit

The standard size of K-HOME flat pack containers is 20 feet (5900mm long * 2438mm wide * 2896mm high). Limited by the size of the shipping container, the customization flexibility is not as high as that of the detachable container.

If you need customization, please tell us your needs and we will provide you with a reasonable design. However, there are quantity requirements for customization.

2. Choose the wall panel color and insulation material

The standard wall panels are white 50mm thick rock wool sandwich panels. However, RAL color customization is available, but there is a quantity requirement, which requires an order of more than 17 sets.

Wall panel materials include:

| No. | Wall Panel Types | Thickness | Options |

|---|---|---|---|

| 1 | Rockwool Sandwich Panel | 50mm/75mm/100mm | the most cost-effective choice |

| 2 | PU Sandwich Panel | 50mm/75mm/100mm | high-end choice, better performance, more beautiful |

| 3 | EPS Foam Sandwich Panel | 50mm/75mm/100mm | the cheapest option, the shorter service life choice |

3. Flooring Options

| Flooring Types | Options |

|---|---|

| Glass Fiber Magnesium Board | General |

| Composite Wood Floor | Customized |

| Solid Wood Floor | Customized |

| Cement Floor | Customized |

4. Roof Options

| Roof Options | Parameter |

|---|---|

| Roofing Material | 0.426mm Steel Wave Roof Tile |

| Roof Sandwich Panel Selection | Thickness: 50Mm |

| Rockwool Sandwich panel/EPS Sandwich Panel | |

| Roof Type Selection | Flat Roof / Pitch Roof |

5. Roof Type Selection

K-home container house has a complete internal drainage system, so the standard configuration is a flat roof. If your area is a lot of rain throughout the year, or you just want to look more beautiful, it is recommended that you choose the double-pitched roof. In addition, the roof color is generally blue and red, please contact us for specific customization requirements.

How To Install a 20ft Flat Pack Container house?

The roof and floor of the container house are integrated during factory design, which significantly simplifies the installation process and shortens the installation timeline. The installation of the shipping container house requires the use of a forklift or lifting equipment.

For non-professionals, building a shipping container house is no easy task. To help you understand the details better, our designers will provide you with detailed installation drawings before the installation process begins. Additionally, we have created an installation video for standard shipping container units.

If you still have questions about the installation process, please contact us directly, and we will provide you with more professional installation guidance.

Multi-Purpose Flat Pack Containers

As a high-quality supplier of modular construction, our modular flat-pack container houses are designed to provide users with sturdy and durable multi-functional application solutions.our modular and prefabricated construction range includes:

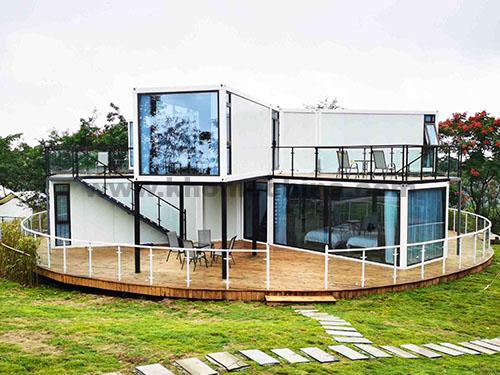

Flat pack office containers: Our versatile portable office containers are designed to provide flexible administrative space. They can be designed to fit the size of the person. Office containers can be customized with up to three floors. The interior can be divided into different administrative spaces, including single-person offices, multi-person offices, meeting rooms, etc.

Portable accommodation containers: Our flat-pack accommodation containers are ideal for temporary accommodation. They can be set up in any desired location for residential needs on construction, mining and industrial sites. These accommodation units can be set up to accommodate different numbers of people. A standard accommodation unit can accommodate up to 8 people with double beds. Of course, you can also customize the design to add functional areas such as toilets and kitchens.

Flat-pack lockers: Our changing rooms provide employees with a safe and practical space where they can change clothes, change clothes and store belongings. Our standard 20ft and 40ft models can include metal lockers, benches, showers, sinks and toilets.

Flat-pack sanitary containers: They provide shower and toilet facilities for construction sites, schools, and temporary sites. Flat-pack sanitary containers are an affordable, durable, and hygienic solution. These modular structures are designed to be waterproof and corrosion-resistant. The interior can be configured with showers and washbasins, as well as customizable options. Flat-pack containers can be easily transported worldwide and are suitable for temporary and permanent use.

Customized Multi-Purpose Flat Pack Container: The container house can be customized according to the needs of the project. Including different colors, layouts, heights, etc. These customized flat pack container houses can be applied to different fields to meet your temporary work and living needs.

Container House application

- container outdoor kitchens

- Construction Camp

- container hotel

- Flat pack container shop

Container House Interior layout

- Staff Office

- Meeting Room

- Container Kitchen

- Launday

- Shower room

- Public Washroom

- Corridor

- Stairs

Download Catalogs

flat pack container house price

The cost of a flatpack container depends on a variety of factors, mainly size, customization and shipping:

- Container size: We offer a variety of standard and custom flat pack containers in different sizes, each with a corresponding price

- Insulation: The type and thickness of insulation you choose will affect the price. Different insulation materials have different costs, such as polyurethane, rock wool or polystyrene (thickness varies from 50mm to 100mm). You can tailor it to the geographical environment where the container will be used.

- Custom additions: Bathrooms, kitchens, furniture, appliances, etc. will add additional costs.

- Shipping: Our flat pack container house are efficiently packed for easy transportation, and the shipping cost varies depending on the destination.

Compared to traditional construction methods, flat pack storage containers can save a lot of construction costs, making them a cost-effective solution for many projects.

prefab modular container house–Best Solutions For dormitory, office, construction site housing

K-home is a global supplier of flat pack container houses. We offer a wide range of prefabricated container houses, including flat-pack container houses. our container houses are composed of detachable prefabricated kits, eco-friendly, affordable, customized service is the best solution for construction site housing. Whether you’re looking for a commercial space a construction site office, prefab school, or engineering camp housing, we can help bring your idea to reality. From planning, design, and material sourcing to building, delivery, and installation, we know that even the smallest details can have a great impact.

As a leading container house manufacturer in China, K-home has been adopting green design concepts and the mission of “making temporary buildings safer and more comfortable”, innovative and unique high-tech, and vigorously developing energy-saving, Prefabricated instant houses with environmental protection and other characteristics. K-home has achieved standardized production, equipped with a complete supply chain management system and professional logistics, installation services, and after-sales service systems to provide global customers with a full range of temporary housing solutions.

Other Different Types of Container Houses

The flat-pack container house is generally used in all areas of society. They are not only used for short-term and long-term construction sites and on-site office space, but also increasingly used as long-term apartment rooms, commercial rooms, restaurant rooms, and shop rooms. Its environmental protection and energy-saving advantages, ease of assembly, sensitivity, safety, comfort and practicality, and low-cost benefits are more and more popular and liked by people.

The following are the applications of container houses:

Why K-HOME Container House?

The container house is our newest type of design since 2019. We have updated many items to make the structure safe and reasonable. As following is our advantage:

1. More Sturdy and Durable

Both our bottom and roof purlin quantity are increased. Other suppliers are 10pcs and ours are 14pcs for the bottom. The mainframe of the product is pressed by a special steel plate and has 4 pcs 160x160x2480mm column, which is sturdy and durable and has strong earthquake resistance and deformation resistance.

2. Complete Drainage System

We modified the water drain system, each column is designed and equipped with 4 water drain pipes. and we design big water drain channel for the roof structure, even for big rain, the house will be very water-proof.

The drainage system of the modular container house is composed of four water channels and downpipes. When it rains, the rainwater on the roof will be collected into the water channel and then flow down through the downpipe of the corner posts to provide an orderly drainage system to achieve better drainage and Easier rainwater collection.

3. Stable And Firm

The container house could be stacked for 3 floors. Our column and roof, and corner joints are stronger, You could move the house very safely and quickly.

4. Fireproof And Soundproof

The thickened Rockwool Wall Sandwich Panel is Class A fireproof, and the side panels have special sound insulation and heat insulation fillers, which can play the role of heat insulation, sound insulation, cold protection, and fire prevention. Can be moved multiple times, reused, hoisted as a whole, the service life is more than 20 years.

Frequently Asked Questions

Related Products

Related Projects

Related Articles

SEND A MESSAGE