Temporary Construction Office Buildings

The impeccable characteristics of the Temporary Construction Office have made more and more customers start to know it, understand it, and love it.

Temporary Construction Office has the characteristics of quick installation, flexible layout, customization, environmental protection, and repeated use. It has become the favorite of investors who frequently replace project sites for a long time.

Whether you are in a downtown area or a remote area, whether you are in the desert or the endless grassland, you can use our prefab container office. Its appearance can be customized according to your needs to ensure our construction site office. It can be integrated with the local environment. Or have a unique style that could let others recognize it for the first time.

Details

Construction Site Temporary Office is Widely Used

K-Home Container Office is the ideal solution for clients who need to complete their office requirements in an extremely short period or need to change their site location frequently.

Temporary Construction Office can add as an addition to the existing building, or as a standalone Prefab Office Container. It could solve your complex container office requirement.

Using the standard modular system, you can build different types of container houses with less time and less environmental pollution.

How We Work With Modular Container Office?

Firstly: Customize the design with our products in the most reasonable and cost-effective way.

Secondly: Production all items in our factory.

Third: Delivery of all container unit material to your site. This way could save lots of money on transportation for you.

Forth: Need to assemble at the site with our professional guidance, or hire our engineer for onsite guidance.

Prefabricated Building Technical Specifications

The following description refers to the specification of container house with Pre-painted Steel Skinned Sandwich Wall Panels

Our container house has CE and ISO certificates. And have the advantages of international transport. The construction is based on a stable steel frame and interchangeable wall panels.

The individual modular container houses can be stood side-by-side in longitudinal and transverse directions without limits.lt also can be stacked to 3 stories height on top of each other Individual sizes of space can be achieved by removing outer wall panels and fitting partitions.

The modular container houses can be delivered in bulk and installed on site. which can save money on transportation.

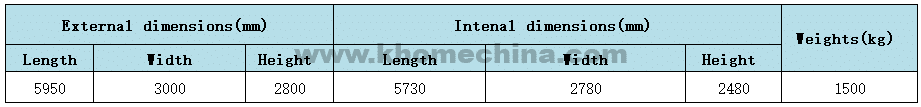

1. Standard measurements and weights of container house

Modular houses can also be customized. It can be designed in dimensions that are exactly adapted to the individual user or to the available space.

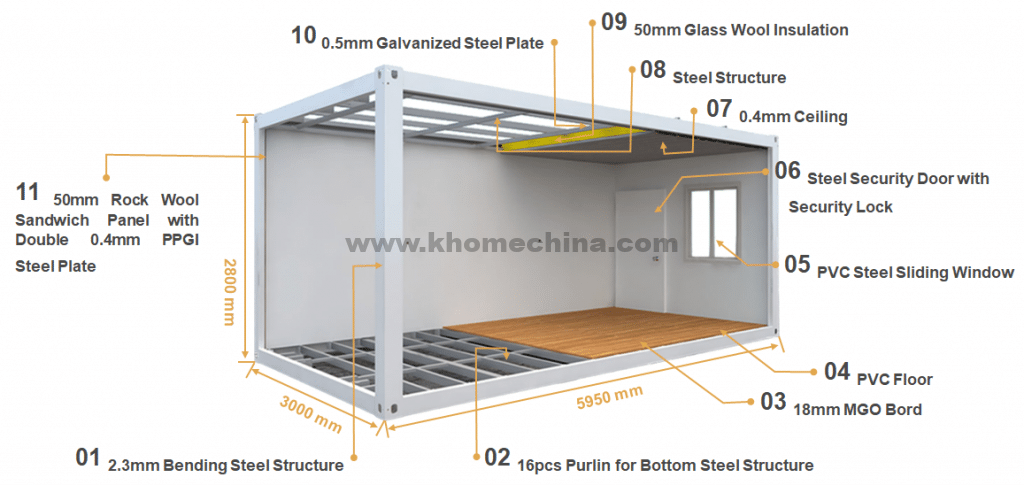

2. Container Unit Specification Details

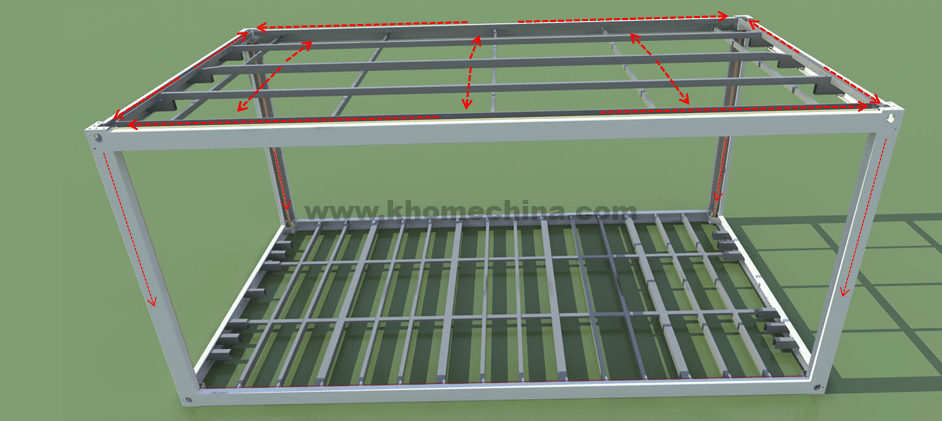

Frame construction: Top &Floor Beams and Corner Posts are 2.3mm thickness galvanized steel structures. Corner Joints 4mm thickness galvanized steel structures. All of them are surface spray treated by machine after being repeatedly polished. The color is glossy and can last for a long time. The features of the steel frame are safe, strong, and corrosion-resistant.

| NO. | TYPE | SIZE | QTY |

| 01 | Long Direction Floor Beam | 5630mm | 2 |

| 02 | Long Direction Roof Beam | 5630mm | 2 |

| 03 | Short Direction Roof Beam | 2680mm | 2 |

| 04 | Short Direction Floor Beam | 2680mm | 2 |

| 05 | Corner Post | 2480mm | 4 |

| 06 | Corner Joints | 160*160mm | 8 |

Roof & Floor system: The purlins are all galvanized square tubes. Their features are firm, have strong corrosion resistance, and have a long service life. For the floor, we will choose 18mm MGO boards with 1.6 mm PVC floor leather, which is good fire, green environmental protection, moisture-proof, wear-resisting, anti-corrosive, and thermal insulation. For the roof, the roof tile is 0.5 mm thick steel sheets, which are pre-coated and color coated. It is strong and corrosion-resistant. The roof Insulation is 50 mm glass wool insulation material, which is fireproof A1 class, non-combustion. The ceiling is 0.4 mm thickness shaped steel plates, which are also pre-coated and color coated.

| NO. | TYPE | SIZE | QTY |

| 01 | Short Direction Roof Purlin | 1.2*40*80*2960mm | 5 |

| 02 | Long Direction Roof Purlin A | 1.2*40*80*5640mm | 1 |

| 03 | Long Direction Roof Purlin B | 1.2*40*60*5640mm | 2 |

| 04 | Long Direction Water Chanel | 85*50*5660mm | 2 |

| 05 | Short Direction Water Chanel | 85*50*2710mm | 2 |

| NO. | TYPE | SIZE | QTY |

| 01 | Short Direction Floor Purlin A | 1.5*40*80*2960mm | 10 |

| 02 | Short Direction Floor Purlin B | 1.5*80*80*2960mm | 4 |

| 03 | Short Floor Purlin C | 30*50*310mm | 4 |

| 04 | Short Floor Purlin D | 30*50*323mm | 18 |

| 05 | Short Floor Purlin E | 30*50*352mm | 8 |

3. Container Unit Waterproof Structure

When there is a lot of precipitation in the rainy season, the container houses need to have a good waterproof function. This is also a problem that many customers are very concerned about.

We K-Home modified the water drain system, each column is designed and equipped with 4 water drain pipes. When it rains, the rainwater on the roof will be collected into the water channel and then flow down through the downpipe of the corner posts to provide an orderly drainage system to achieve better drainage and Easier rainwater collection.

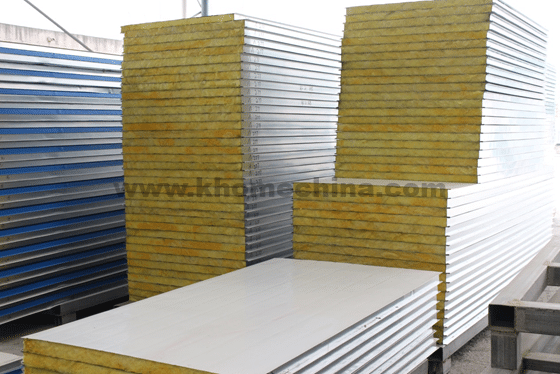

4. Container Unit Wall Panel

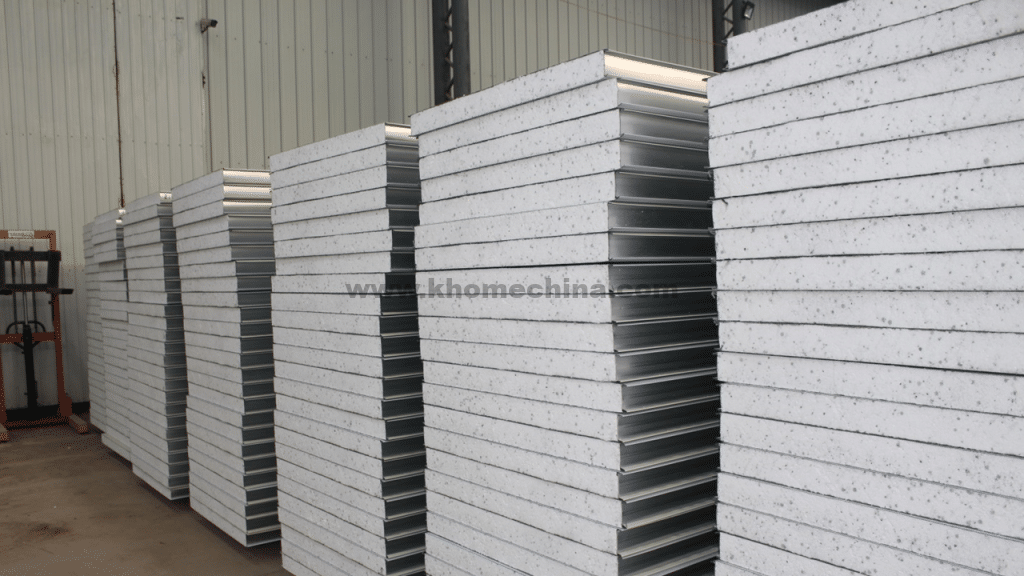

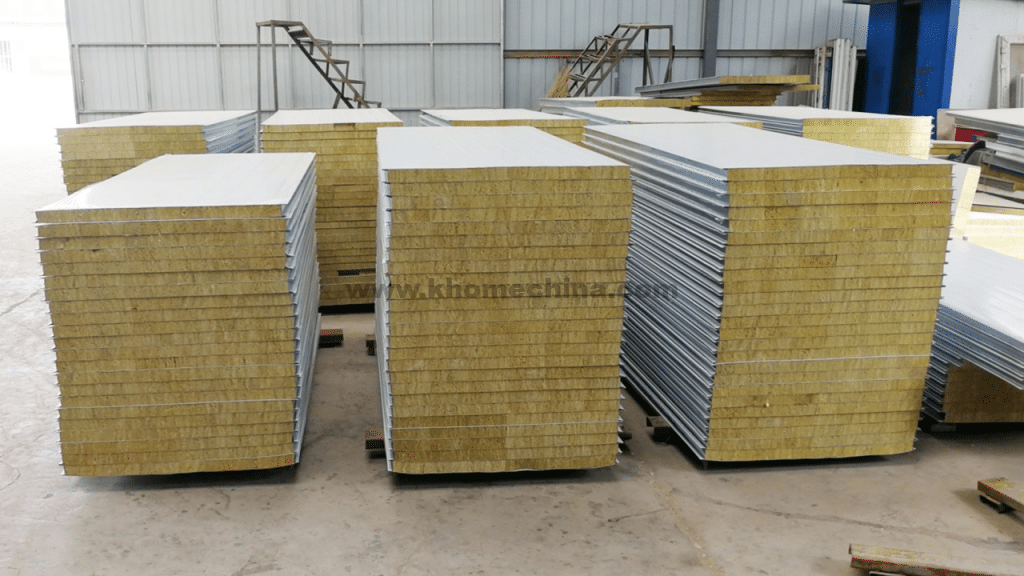

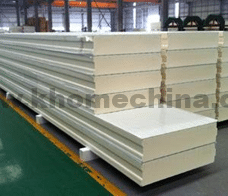

The exterior & interior claddings are all 0.4mm thickness galvanized and pre-painted steel plates. The insulation is 50 mm thickness Rockwool. The insulation materials have many different options, like Glass wool sandwich panels, EPS sandwich panels, Rockwool sandwich panels, PU sandwich panels and etc. What’s the difference between these insulation materials?

Glass wool sandwich panels: It uses glass as the main raw material and mixes with various other auxiliary materials in a certain proportion. The suitable temperature is only about 350 degrees. Feature: Light density, small thermal conductivity, large absorption coefficient, good flame retardant performance. Generally used for heat preservation below 200 degrees Celsius, mostly used for heat preservation of general buildings such as steel structure workshops, breeding greenhouses, or low-temperature pipes.

EPS sandwich panels: EPS sandwich panels, with a density of 15-50kg/m³, the thermal conductivity of 0.030-0.045W/(m·K), and an operating temperature of <70℃. Polystyrene beads, a rigid closed-cell foam plastic that is heated and formed in a mold. The temperature is low, about 70 degrees Celsius. Generally can be used for building external wall insulation, curtain walls with rock wool so on.

Rockwool sandwich panels: Use refined basalt as the main raw material, then add a special binder and dustproof oil. The temperature is high, about 600 degrees Celsius. Fireproof is A+. Generally can be used for building external wall insulation, curtain walls with rock wool, fire isolation belt, and so on. Good adiabatic performance, Excellent sound insulation, and sound absorption performance.

PU Sandwich panels: They are currently internationally recognized as the best fireproof and thermal insulation board for building enclosures. It has low thermal conductivity, good load resistance, high flexural strength, no water absorption, no decay, no insect bites, good flame retardancy, and a large temperature resistance range. This new lightweight building material is a perfect combination of color-coated steel plate and polyurethane and is the development direction of lightweight building materials. It provides an excellent choice for industrial building enclosure systems.

Related Products

Related Project

SEND A MESSAGE