Prefab Container Homes South Africa

Looking for a cost-effective, high-quality, and quick-to-deploy housing solution of Prefab Container Homes South Africa for your projects or workforce? K-Home’s Prefab Container Homes are the ideal choice!

With over 15 years of expertise in modular buildings, we specialize in Prefab Container Homes Africa which combines prefab containers durability with light steel framing technology. Our designs are easy to transport, quick to assemble, and fully customizable—perfect for remote or urban locations across South Africa.

K-HOME is a trusted brand. We offer affordable and high-quality African prefabricated container homes for residential, commercial and industrial use in Africa. From custom design to on-site installation, we will handle everything—saving you time and hassle. Our installation team in Africa ensures smooth, low-cost setup with no communication barriers.

Need a fast, reliable, and budget-friendly solution of Prefab Container Homes Africa? Contact us today for a customized quot!

What are prefab container houses?

Prefab container houses are like “Lego houses” – they’re pre-built in a factory, then shipped and assembled quickly on-site, just like stacking blocks!

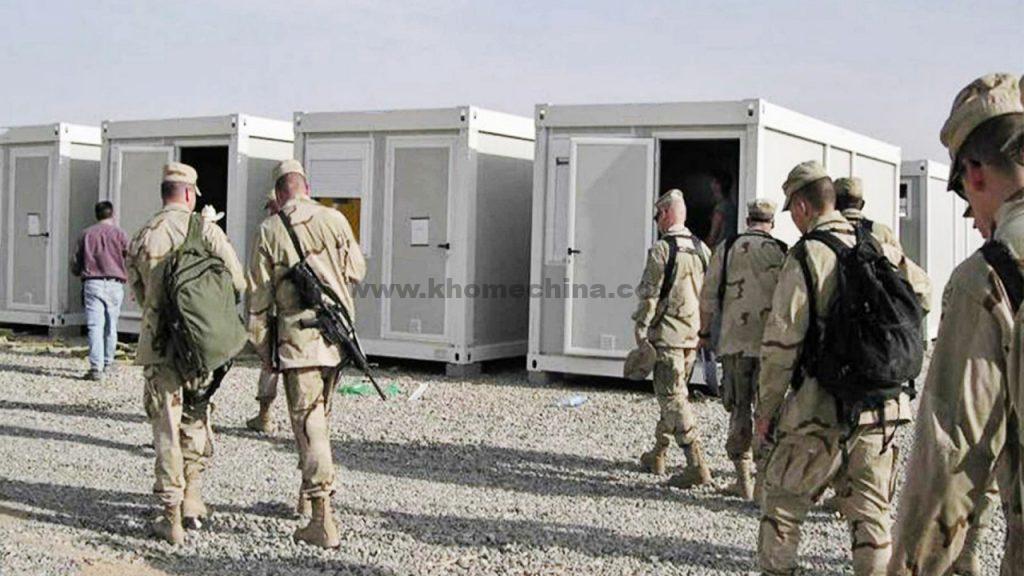

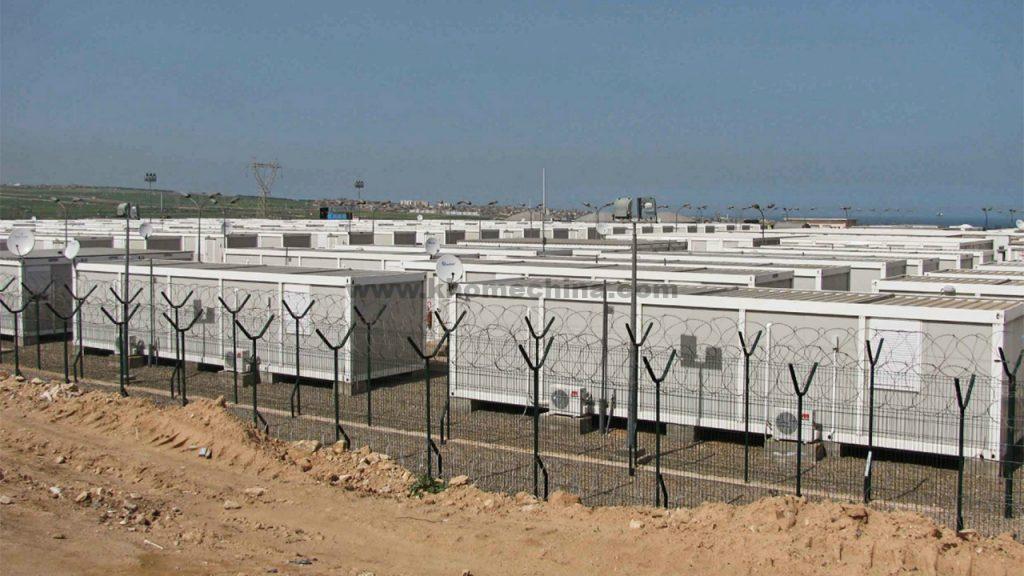

K-home container houses have been exported to many countries in South Africa, including Ethiopia, Somalia, Kenya, Rwanda, Mali, Ghana, Niger, etc. We have different types of temporary building solutions for you to choose from, such as PEB Steel Buildings, Flat Pack Container House, or Low Cost Prefabricated Houses. You can choose any of them as an alternative to expensive traditional construction. This is a great option for remote construction sites and sites that require welfare units.

Container Homes South Africa Pictures & video

Why The Container Is Very Popular In South Africa? Because It Has The Following Characteristics:

- Efficient Shipping & Logistics

Standard shipment: 11 units per 40-foot container.

Bulk order advantage: For orders exceeding 30 units, each 40-foot container can put 14 units, significantly reducing shipping costs. - All-Inclusive, Budget-Friendly Solution

High-quality steel structure: hot-dip galvanized & painted for long-term rust resistance, Durable wall panels, PVC-carpeted floor, and weatherproof roof

Regular Configuration: 2 windows, 1 door, and electrical wiring

No hidden costs: everything is included for a seamless setup. - Superior Anti-Corrosion Protection

The entire steel framework undergoes hot-dip galvanization and multi-layer painting, ensuring decades of rust-free durability even in harsh environments. - Quick & Easy On-Site Assembly

No heavy machinery required: all components are screwed together manually, eliminating the need for cranes or forklifts, which makes it the ideal housing solution for rural, suburban, or remote areas with limited infrastructure.

Hassle-free installation: includes step-by-step assembly guides & video tutorials - Space-Saving & Multi-Story Design

Stackable up to 3 floors: optimizing land use and reducing foundation costs. - Flexible Sizing Options

Standard dimensions: 3m (W) × 5.95m (L) × 2.8m (H)

Customizable sizes available: or as per requirements. - Weather-Resistant Roof System

Efficient drainage design: with 4 PVC pipes (installed at each corner) to prevent water accumulation.

Optional roof styles: Flat, pitched, or sloped roof configurations available. - Installation

We have installation team in Africa, and the workers are local Africans and can speak the local language, which can save airfare and communication costs.

Container Homes South Africa Price

The cost of container houses in South Africa is related to many factors, such as the thickness of the steel frame used in the portable container house, the material of the wall panel, the degree of interior decoration, the distance of transportation, the size and type, and so on. The material of the structure determines the quality and service life.

At k-home, we offer a variety of prefabricated container house units, but the two preferred options are detachable containers and flat pack containers. Both prefabricated containers offer three levels of cost options, and you can choose the appropriate construction type and cost level according to your needs and budget.

detachable container house for sale

⭐⭐⭐

basic

⭐⭐⭐⭐

standard

⭐⭐⭐⭐⭐

premium

flat pack container house for sale

⭐⭐⭐

basic

⭐⭐⭐⭐

standard

⭐⭐⭐⭐⭐

premium

Advantages of Container Homes South Africa

Convenience:

Easy to transport, easy to assemble, especially suitable for container house units that frequently change construction sites. Easy to dismantle and assemble, superior performance, and lightweight. The house is a whole structure with a frame inside, the wall is steel plate and can be finished with a wooden board. Can be relocated as a whole. Extremely low maintenance costs, with a service life of 20 years or more.

Sturdy and Durable:

The structure is composed of steel, stable and firm, with good anti-vibration. It has strong resistance to deformation; good sealing performance, strict manufacturing process makes this kind of activity room has good water tightness.

Good value for Money:

Reusable. Recycling a waste container can save 1.7 tons of steel and 0.4 cubic meters of wood, and reduce 3.49 tons of carbon dioxide. In addition, container module technology can reduce the construction cycle by 50%, which means you will also reduce construction costs by 50%.

Strong Design:

Container housing has the characteristics of modularity and can be a personalized combination. Can derive many combination spaces. Such as offices, conference rooms, schools, hospitals, dormitories, kitchens, bathrooms, etc.

Maybe you need our container houses for your future projects. Please contact our support teams. Email:inquiry@khomechina.com

What is the difference between prefab container houses and shipping container houses?

While both prefab (prefabricated) container homes and shipping container houses fall under modular construction, they have distinct differences in materials, design flexibility, cost, and construction methods. Here’s a clear breakdown:

Main Material & Structure

Prefab Container Homes:

1. Constructed from light steel frames, and composite panels (not limited to containers).

2.Fully customizable sizes as you need.

3. They are connected by bolt and screw; no need to cut or weld.

Shipping Container Houses:

1. Built from modified shipping containers (typically 20ft or 40ft).

2. Limited by the container’s original dimensions (width fixed at ~2.4m).

3. Require cutting/welding to combine units or create openings (doors/windows).

Design Flexibility

Prefab Container Homes:

1. Tailor-made layouts (open-plan, multi-story, curved walls, etc.)

2. Higher ceilings (up to 3m+), larger windows, and flexible room divisions.

3. Easier to insulate and adapt to extreme climates.

Shipping Container Houses:

1. Modular but constrained by the rigid steel box structure.

2. Combining multiple containers requires structural reinforcement.

3. Limited ceiling height (~2.6m unless modified).

Cost & Production Speed

Prefab Container Homes:

1. The cost is optimized for cost-efficiency (no wasted space or excess steel); no need to modify.

2. The production time is faster than shipping container homes because it is faster for large-scale production (factory-built panels snap together on-site).

Shipping Container Houses:

1. The initial material cost (if using used containers) is higher than prefab container homes

2. And plus higher modification costs , which is much higher than prefab container homes.

Durability & Comfort

Prefab Container Homes:

1. Designed with thermal insulation, ventilation, and moisture control, which make it more suitable used for living, office, kitchen and etc

Shipping Container Houses:

1. Extremely strong but prone to condensation and heat transfer (steel conducts temperature).

usage areas of Prefabricated container

How to choose the suitable wall panel for Prefab Container Homes?

There are many types of sandwich wall panels, including polystyrene foam panels (EPS), rock wool panels, polyurethane-sealed rock wool panels, polyurethane (PU), and polystyrene sandwich panels. The price reference is: rock wool panels < EPS < PU edge-sealed rock wool panels< PU panels < PIR panels.

- If your climate is humid and the temperature is moderate, can choose EPS, which is waterproof.

- If your climate is dry and the temperature is moderate, can choose Rock Wool, which is better fireproof.

- If your climate is humid and the temperature is hot or cold, can choose PU, which is better heatproof and soundproof.

- If your climate is dry and the temperature is hot or cold, want better soundproof, can choose PIR, which is better heatproof, soundproof and fireproof.

How to choose a suitable Foundation for Prefab Container Houses?

When setting up an onsite prefab container houses, selecting the appropriate foundation is crucial for ensuring the stability, longevity of the structure and limited budget. The regular foundation is Dot Pillars, Strip, and All Hardened. If your budget is limited, you can choose dot pillar, which is easy to build, so that it can save the foundation cost and workers cost.

Foundation for Prefab Containers-Dot Pillars Foundation for Prefab Containers-Strip Foundation for Prefab Containers-All Hardened

Frequently Asked Questions

Recent Blogs

SEND A MESSAGE