Prefabricated Toilet Blocks

ablution blocks / container toilet / container WC / toilet blocks / modular toilet / portable toilet blocks

Multi-purpose portable toilet blocks for sale

What are Prefabricated Toilet Blocks?

Prefabricated toilet blocks are a modular toilet solution made factory-based, fast-installation, and construction-efficient. It is mostly a light steel structure system that adopted factory prefabrication, and then modular installed on the construction site. Toilets that are prefabricated, pay attention to water, drainage, and moisture resistance. The Prefabricated Toilet Blocks also have good sealing and are resistant to earthquakes, it can adapt to construction sites with frequent changes.

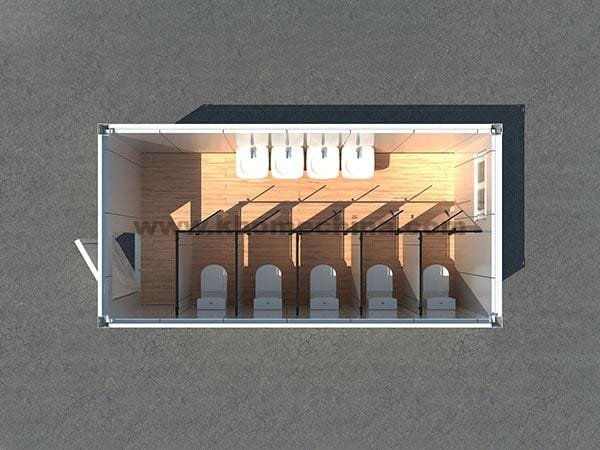

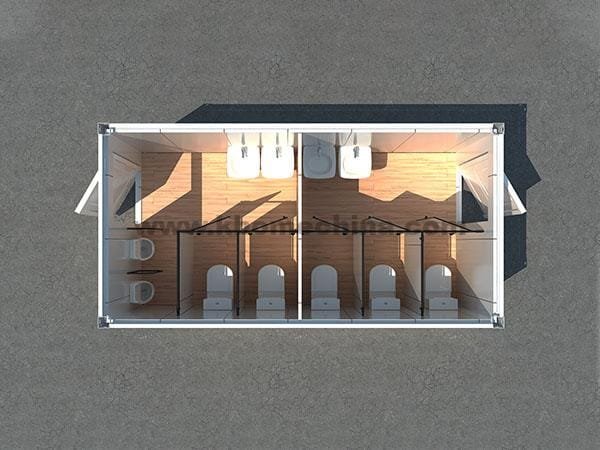

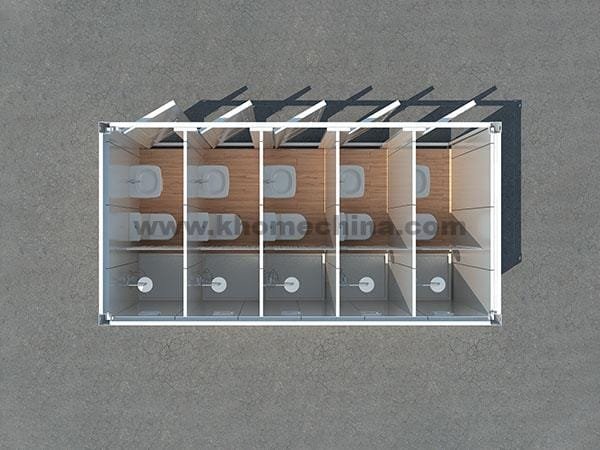

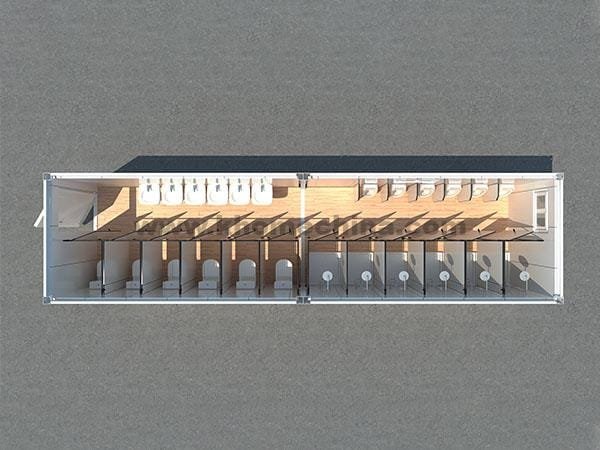

The Prefabricated Toilet Block installation needs to go through a series of strict steps including basic cleaning, measurement and pay-off, support installation, hoisting installation, and waterproof treatment in the construction process. These processes guarantee the strength and sustainability of the bathroom that you are employing. In addition, the Prefabricated Toilet Blocks design also takes into account a variety of functional needs, such as a shower in combination with a washbasin toilet and other facilities, so that the use of bathroom space is more reasonable.

The prefabricated container room toilet has lots of advantages, such as fast construction speed, high efficiency, environmental protection, and energy-saving characteristics. It is necessary to find solutions to modern architecture.

Why are Prefabricated Toilet Block Gaining Popularity?

1. Easy & Fast Installation

There are different types of toilet blocks: if the portable toilet & ablution block is on the second floor, we can raise the indoor floor so that there is enough space for the sewage pipe. If the portable toilet & ablution block placed on the first floor, then the indoor floor does not need to be raised, you only need to reserve the location of the sewage pipe when making the foundation.

The prefabricated bathroom units can be equipped with squat toilets, toilets, urinals, sinks, mirrors, etc. You can also add a shower and floor drain. Regular bathrooms will be equipped with lights, switches, and exhaust fans. The bathroom container room is the same as the ordinary container; all parts are assembled with screws and bolts. Only three or four workers can assemble a toilet block in a few hours.

2. Robust Materials

Prefabricated toilet blocks are popular with large spaces. It is constructed with rust-resistant galvanized steel frame, fire-resistant floor and sandwich panel material. Container houses can be designed and built according to the requirements of the construction site or personal hobbies and their interiors. Decoration can also be done according to personal preference. You can combine different container houses into hotels, dormitories, coffee shops, etc. for various purposes and shapes. Most young people like its stylish look. Our factory will produce all the required assembly parts, your workers only need to assemble all the parts together on site.

The modular toilet is also a prefabricated house with galvanized steel as the main frame, sandwich panels as the wall panels, doors, windows, ceilings and other accessories, which are connected by bolts. The overall structure includes a complete roof and floor structure, which is earthquake-resistant and wind-resistant. The design service life can reach 15-20 years. Compared with other box rooms on the market, we also specially upgraded the ground structure. That is we added more ground purlins along the length. In this way, the distance between the ground purlin and the ground purlin will become smaller, which can better protect the floor. Insulation can also be added to the ground structure if required by the customer.

3. Easy Clean & Maintenance

For the special use environment of the prefabricated toilet blocks, we have researched and produced an upgraded version of the material configuration for customers to choose. First of all, we can replace the fireproof board on the ground with a cement board, which not only increases the bearing capacity, but also has a better waterproof and moisture-proof effect, so whether you use it as a public toilet or a public shower, you don’t have to worry about the corrosion of the ground. Secondly, we can also replace the PVC floor leather on the ground with patterned aluminum plates, so that the corrosion resistance of the ground is greatly improved, and it is very easy to clean, so there is no need to worry that any cleaning agent will cause damage to the ground, guarantying the long service life.

4. Portable Toilet Blocks – Easily installed anywhere

The prefabricated toilet blocks are all dry construction and are not affected by the environmental season. It adopts the mode of factory prefabrication and component installation, which can greatly improve the construction efficiency and construction cost. After the plant is completed, it is directly transported to the site, and can be used after quick installation, reducing environmental pollution caused by waste.

5. Environmental Sustainability Considerations

95% of the materials in the prefabricated toilet blocks can be recycled, making it green and pollution-free. And all use energy-saving walls, thermal insulation, heat insulation, sound insulation effect is good, can reach 50% energy saving standard.

Can prefabricated toilet blocks be moved to different locations and reused?

Of course! Prefabricated toilet blocks are a factory-produced modular toilet solution. They offer the advantages of fast installation and efficient construction. These toilets are typically built with lightweight steel frames, prefabricated in the factory, and then transported to the site for assembly. Prefabricated toilets are designed with excellent sealing properties and are waterproof and moisture-proof. In addition, their portability allows them to be moved anywhere, making them ideal for dynamic construction environments.

The installation process of these toilets involves several meticulous steps, including thorough site preparation, precise measurements, support installation, lifting, and waterproofing. These procedures are essential to ensure the stability and longevity of the bathroom. Prefabricated toilet blocks are also designed to meet various functional requirements, integrating functions such as showers, washbasins, and toilets to optimize space utilization. With their fast construction, high efficiency, and environmentally friendly characteristics, prefabricated toilet block toilets have become an important solution in contemporary construction.

What Factors Should Be Considered In The Design Of Prefabricated Toilet Blocks?

The design of Prefabricated Toilet Blocks is a complex and multifaceted process that requires comprehensive consideration of factors such as architecture, structure, decoration, and equipment to ensure their functionality and safety.

1. Functional zoning and layout

Reasonable functional zoning is the core of prefabricated bathroom design. Bathroom design should comprehensively consider architecture, structure, interior decoration, equipment and other professions, and reasonably layout to ensure dry and wet separation and clear functional zoning. For example, the washing area is usually arranged on the outside to achieve dry and wet separation and maintain the unity of the entire bathroom. In addition, barrier-free design and aging-friendly needs should also be considered to ensure that all users can use it conveniently.

We provide a variety of configuration examples for your reference. Of course, if you have customized requirements, you can communicate with us directly to obtain a unique design solution.

2. Material Selection and Waterproof Treatment

Waterproofing is an important part of Prefabricated Toilet Blocks design. K-HOME’s prefabricated bathroom with waterproof flooring. At the same time, the selection of low water absorption, wear resistance, pollution resistance, easy to clean, corrosion resistance material as the floor decoration material, and the use of waterproof wallpaper as the wall surface layer. These measures can effectively prevent leakage problems and improve the service life and safety of the toilet.

3. Drainage System Design

The design of the drainage system directly affects the experience and safety of the toilet. K-HOME’s prefabricated toilets can be drained in two ways: wall drainage and floor drainage. Depending on the overall layout of the building, the client is free to choose. In the shower room, KHOME’s prefabricated container room will also be equipped with an extended floor drain with high flow to prevent clogging.

Note:If your toilet block is a one-story structure, then any drainage solution can be used. If your portable bathroom is a two-story structure, then the drainage design of the second floor can only choose the wall drainage method. Below is the drainage design visualization we provide, you can check it out to get a better understanding.

4. Ventilation and Lighting Design

Good ventilation and lighting are key factors in improving bathroom comfort. K-HOME’s Prefabricated Toilet Blocks will be equipped with exhaust fans, and the Windows can be either sliding Windows or shutters. In addition, the lighting arrangement should meet the requirements of lighting, heat protection, cold protection, and prevent exhaust backpouring.

5. Equipment and Pipeline Layout

The layout of equipment and pipelines should be reasonable and easy to maintain. K-HOME’s prefabricated bathroom ceiling adopts an integral ceiling, and the electrical access and distribution are set in the ceiling. At the same time, the use of exposed wires is easy to maintain. In addition, the selection and design of sanitary ware and storage cabinets should also be considered, and the selection and design should be combined with factors such as space size, drainage type and connection method.

6. Construction and Installation

The construction and installation of Prefabricated Toilet Blocks are important links to ensure their quality and performance. K-HOME prefabricated bathroom modules produce all materials according to customer requirements, shortening the on-site construction time and ensuring the quality of decoration.

7. Detail handling and maintenance

Detail handling and maintenance are necessary conditions to ensure long-term use of the bathroom. The design of the bathroom should fully consider the requirements of maintenance and updates. For example, sealant should be applied at the junction between the facial cleanser and the wall, and between the urinal and the wall to prevent moisture infiltration and contamination. In addition, the facilities and equipment in the bathroom should be regularly inspected and maintained to ensure their normal operation and service life.

The design of Prefabricated Toilet Blocks is a comprehensive project that requires consideration and planning from multiple aspects. Through reasonable design layout, selection of suitable materials and technologies, scientific drainage and ventilation systems, and meticulous construction and maintenance, Prefabricated Toilet Blocks can ensure good performance and long service life. Only by fully considering these factors can a reasonable and efficient prefabricated bathroom design scheme be obtained.

How Fast Can The Prefabricated Toilet Blocks Be Installed?

Prefabricated toilet blocks, due to their modular and factory-prefabricated characteristics, have a significantly faster installation speed than traditional building methods. We can analyze in detail the installation speed of prefabricated container bathrooms.

Prefabricated toilet blocks are built in a factory-prefabricated manner, with most of the work being completed in the factory. By producing these components in a controlled environment, the overall quality is improved and the time required for on-site construction is greatly reduced.

Prefabricated container bathrooms are fast to install and have a short construction period. Four people can complete the installation of a single box in three hours. A key benefit of this fast installation process is that prefabricated container bathrooms can be shipped to the site fully assembled and can be used immediately once water and electricity are connected. In addition, the design of the container bathroom is very environmentally friendly and does not produce any construction waste. By utilizing factory prefabrication and assembly technology, the overall construction time is greatly shortened, saving labor and time costs. This approach not only speeds up the construction process, but also improves the quality of the project.

Frequently Asked Questions

Related Products

SEND A MESSAGE