What Is Steel Frame Structure?

The steel frame structure is a structure composed of steel beams and steel columns that bear the entire load of the house. All components are produced in advance in the factory and connected on site by bolts and screws.

The modular manufacturing process enables efficient production of steel components and significantly shortens construction time. This time-saving advantage not only speeds up project completion, but also saves costs by minimizing labor costs.

The walls of frame structure houses do not bear weight and only serve as enclosures and partitions.

Because steel is 100% recyclable, it means that it can be reused indefinitely without affecting its quality or performance. The recycling process consumes less energy and reduces greenhouse gas emissions, making it an environmentally friendly choice compared to non-recyclable building materials.

Types of Steel Framed Buildings

According to the specifications of the frame, that is, the amount of steel used, the frame structure can be divided into light gauge steel frame structure and heavy steel structure.

Light steel frame structure

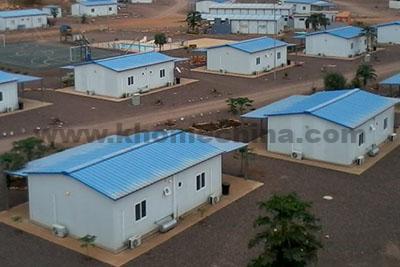

Generally used for temporary construction projects, such as construction sites, oil fields, gas, mining projects, etc. Light steel structure can quickly build temporary office areas, workers’ dormitories and storage spaces to meet the needs of personnel placement and material storage in the early stage of the project, and can be flexibly dismantled or relocated as the project progresses. Due to its fast installation and high cost performance, it is now widely used all over the world. The design life of light steel structure can generally reach up to 20~25 years. The amount of steel used can be reduced or increased according to project requirements to match the required service life, thereby saving investment to the maximum extent.

Common Types of Light Steel Frame Structure:

Prefabricated building: It is composed of light steel structure and maintenance materials, and is widely used in construction sites. It requires a flat cement foundation in advance; It contains less steel and has a lifespan of about 10 to 15 years; When moving, it needs to be disassembled and reassembled, which will damage some materials and shorten the lifespan of the house. The price is about USD 50/sqm~USD 80.00/sqm.

Container House Building: Modular design, no need for complex foundation, can reduce some costs from the foundation fee. Contains more steel, is stronger, and has a longer service life. It can be transported as a whole without disassembly when moving; The appearance is better, and the design can be customized; The price is about USD 100/sqm ~ USD 120.00/sqm.

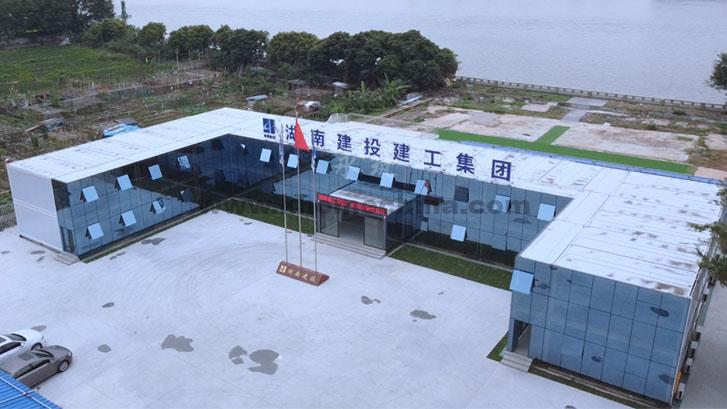

Heavy steel structure

Generally used for large-span warehouses and heavy-duty workshops, the structure and steel consumption can be customized according to the load requirements of the customer’s country, such as wind resistance, earthquake resistance, rain and snow, etc. The life of heavy steel structure is generally 50 years, meeting the requirements of permanent building life.

Engineers will use advanced structural analysis software, combined with precise mechanical calculations, to accurately design structural solutions that adapt to local climate and geological conditions, and reasonably plan the amount of steel used to achieve cost optimization control while ensuring the safety and durability of the building.

Portal frames is common type of steel frame structure, consist of rigidly connected steel beams and columns that form a moment-resisting framework. This system is especially effective for low-rise industrial buildings where large, open floor areas are needed without interior supports, such as in warehouses, workshops, and aircraft hangars. The shape resembles a doorway, which is how the term “portal” originated.

Wall Systems for steel frame buildings

Common enclosure structures are sandwich panels, corrugated steel sheet and cement board composite wall.

Sandwich panels: composed of double-sided steel plates and insulating core materials, the middle core materials can be EPS, rock wool and polyurethane.

1. EPS sandwich panels: Commonly used are 950mm in width, 50mm, 75mm, 100mm, 150mm in thickness; It isnot fire, usually more than 10kg can be added with flame retardants to improve the fire resistance, but the overall fire resistance is low.

2. Rock wool sandwich panels: Commonly used are 950mm in width, 50mm, 75mm, 100mm, 150mm in thickness; rock wool color steel sandwich panels with customizable lengths, referred to as rock wool panels. Fireproofing reaches Class A, the highest level of fireproofing performance. It will not burn when exposed to fire.

3. Polyurethane sealed rock wool panel.

The common ones are 1000mm in width, 50mm, 75mm, 100mm, and 150mm in thickness; the length can be customized. Because the double-sided edge-sealed polyurethane increases the strength of the wall, and the bulk density of rock wool is increased to more than 100kg, the quality of this sandwich panel has been greatly improved compared to ordinary rock wool panels. The fireproof level is still Class A of rock wool.

The connection methods include socket-type and hidden nail-type installation, and the surface of the board can be seamlessly spliced and seamed.

4. Polyurethane sandwich panels

The common ones are 1000mm in width, 50mm, 75mm, 100mm, and 150mm in thickness; the length can be customized. The bulk density of polyurethane is 38~45kg/m3; because the sandwich core material is all made of polyurethane, the strength of the wall is greatly increased. Polyurethane itself has Class B fireproof and excellent waterproof performance. It can self-extinguish when encountering open flames, and its thermal insulation performance is also the best. But the cost is also the most expensive.

This panel has many forms of connection ways. The tongue-and-groove type is a common vertical installation board. After installation, there is no gap and it is mostly used in container houses, prefab buildings, and cold rooms. In addition, there are horizontal installation boards with gaps to increase the three-dimensional sense, which are mostly used for the exterior walls of industrial plants.

5. Glass magnesium rock wool sandwich panel

The common ones are 950mm in width and 50mm, 75mm, 100mm, and 150mm in thickness; the color steel sandwich board with customizable length is also called purification board, which is often used in purification workshops. Fireproofing reaches A+ level, the highest level of fireproofing performance. It does not burn when encountering fire. The fireproof time can reach 4 hours, which is higher than rock wool. The strength is also very high. It can be operated by people.

6. Corrugated steel sheet

The simplest wall treatment method. Since there is no insulation layer, it is not suitable for use as a living place. It is commonly found in industrial or agricultural buildings such as garages, farm sheds, simple warehouses, factories, etc.

Steel Frame Structure Building VS Traditional Cement Building

1. The construction of the steel frame structure is rapid, and the emergency advantages are apparent, which can meet the sudden storage needs of the enterprise.

2. The steel frame structure is dry construction, which has outstanding environmental protection advantages. It can reduce the impact of project construction on the environment and nearby residents, which is better than the wet construction of reinforced concrete buildings.

3. Steel frame structure building can save construction costs and workers’ costs, compared with traditional concrete warehouses. The cost of building a steel structure warehouse is 20% to 30% lower than a typical warehouse construction cost, and it is more secure and stable.

4. The steel structure is light in weight, and the building materials used in the walls and roof are much lighter than those in brick-concrete walls and terracotta roofs, which can effectively reduce the overall weight of the steel structure warehouse without compromising its structural stability. At the same time, it can also reduce the transportation cost of components formed by off-site migration.

5. Earthquake resistance: The steel frame structure can absorb and dissipate energy through deformation, reduce damage to the structure, and has better earthquake resistance.

In contrast, the tensile strength of the brick-concrete structure is low, the stress is concentrated, and the structure is easily damaged due to wall cracks during an earthquake, and the earthquake resistance is relatively weak.