Modular Office Building in Cameroon | K-hOME Case Study

From challenge to solution: See how K-HOME designed a client-approved modular office building for Cameroon in 10 days. This case study reveals our process. We combined efficient modular methods with close client collaboration. The result was a faster timeline and significant cost savings.

From Design to Turnkey Solution: Modular Office in Cameroon | project overview

| PPRJECT INFORMATION | PROJECT PERFORMANCE |

| Project Name: Modular Office building Expansion Project in Cameroon | From Inquiry to Approved Design: 10 Working Days • Quick response; initial design and 3D renders delivered in 1 day • Efficient communication with fast decision-making |

| Client: A freight company in Cameroon needing urgent office space expansion. | Expert Advice Built 100% Client Trust • Proactively identified 3 key design challenges. • Client fully understood and approved our optimization suggestions. |

| Core Need: A fast, cost-effective modular container solution based on their technical drawings. | Value Engineering Saved Cost & Time • Standardized 15 different window/door sizes into just 2-3 types. • This significantly improved production efficiency and reduced cost. |

| Core Challenges: 1. Complex 2-story design with a unique roof and corridor. 2. Client’s preferred color was not available for small orders. 3. Too many custom window/door sizes, increasing cost and time. | Smooth Collaboration & Project Management • Demonstrated excellent teamwork across our sales and design departments. • Used 3D renders for clear communication, ensuring everyone was aligned. |

| Our Solution: K-home provided an all-in-one service: professional design optimization, 3D visualization, and supply chain management. | Strong Foundation for Success • The final approved design created a solid foundation for the smooth start of production and construction. |

modular container office building in cameroon | Full Project Process Analysis

Ⅰ. Project Background: An Urgent Need for Expansion

This section outlines the client’s initial situation and core requirements that kicked off the project.

In September 2023, K-home was contacted by a freight forwarding company in Cameroon. Due to significant business growth and an increasing workforce, the client had an urgent need to expand their existing office facilities.

Having previously built an office using second-hand shipping containers, which proved costly, the client made a strategic decision. This time, they opted for a more efficient and cost-effective approach by using purpose-built modular detachable containers for the new expansion.

The client specifically reached out to K-home because they were impressed by the portfolio of refined container-based offices on our website. They trusted us to develop a perfect prefabricated office solution and provide a quotation based on their technical drawings, with an emphasis on speed.

Ⅱ. Project Challenges: Bridging Design and Modular Feasibility

We reviewed the architectural drawings from the client. After an initial assessment, the office building project is well-suited for modular container construction.

However, we have identified challenges in certain design parameters and their technical execution, which require communication and confirmation with the client.

The key that needs adjustment involves the following three aspects:

1. Structural Adjustment Based on Theoretical and Technological Deviations

The proposed office is a two-story structure with a complex design. This includes an irregular layout, separate corridors, and a sloping roof.

However, the provided drawings are based on conventional architectural theory. They do not fully account for the standardized nature of modular container construction.

For instance, the design for the corridor support columns and the sloping roof’s corner joints could lead to potential errors during fabrication and on-site assembly.

Therefore, we need to optimize these structural details to align with container manufacturing processes.

2. Building Exterior Color Adjustment Instructions

Regarding the building’s exterior color. There are minimum order quantity requirements for the colored steel sheets used in modular containers.

However, the color initially specified by the client does not meet the minimum order quantity requirements for the project size. The client needs to select a suitable option from the compliant color card we provide.

3. Value Engineering for Windows and Doors

The initial plans specified nearly 15 different window and door sizes. This excessive customization would disrupt production scheduling, increase costs, and complicate installation. We proposed consolidating these into 2-3 standard sizes to optimize efficiency and cost.

4. Ensuring Structural Integrity Against High Winds

Given the project site’s frequent exposure to strong winds, specific wind-resistant reinforcement measures must be incorporated into the structural design to ensure the building’s structural integrity and wind resistance stability.

Ⅲ. The K-HOME Solution: Tailor-made Integrated Solutions

1. Proactive Communication & Collaborative Alignment

Upon identifying key challenges, we proactively scheduled a video conference with the client. Using annotated drawings and relevant case studies, we clearly explained the technical rationale and benefits behind each proposed adjustment. This transparent approach built trust, leading the client to fully understand, endorse our recommendations, and authorize us to proceed with revised drawings.

2. Rapid Design Iteration Using 3D Visualization

Based on the original drawings and the consensus reached in the meeting, our design team quickly delivered revised technical drawings that adhered to modular principles within just 1 business day, while simultaneously creating high-resolution 3D renderings.

The renderings clearly presented the office building exterior facade and the decorative effect of the secondary roof, intuitively showcasing the actual scene after the design was implemented. These were then sent to the client for confirmation.

3. Streamlined Feedback Loop for Final Approval

We established an efficient feedback process. The client reviewed the initial proposal and provided concentrated feedback within two working days. Our team then made prompt adjustments and engaged in multiple refinement meetings. This iterative and collaborative process culminated in the final design sign-off on the 10th working day, creating a solid foundation for production.

4. Expert Wind-Resistance Engineering

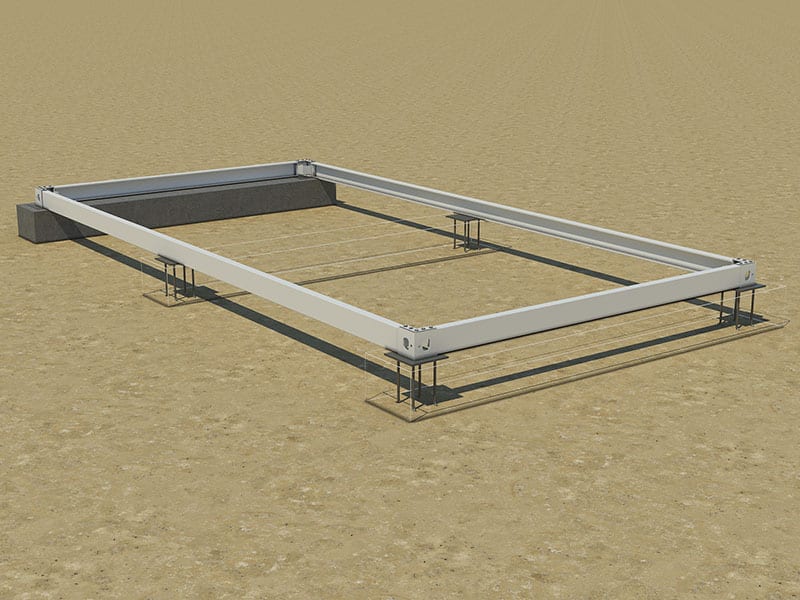

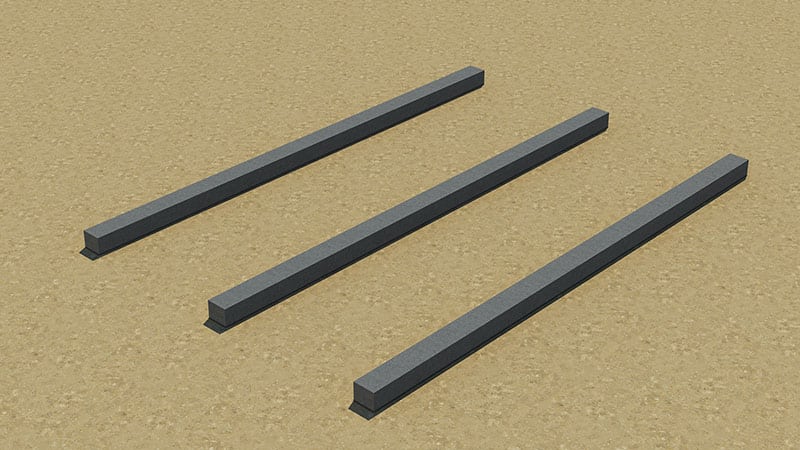

To address the client’s concern about local wind conditions, we deployed our proven reinforcement system, honed in hurricane-prone regions like the Philippines and Jamaica.

Reinforcement Between Adjacent Containers: We specified high-strength external fasten bolts for all vertical and horizontal connections, tying individual containers into a single, rigid structure to prevent shifting in strong winds.

Windproof Fixing Treatment for Foundation: We designed a foundation with pre-embedded galvanized steel plates. The container base frames are fully welded to these plates, permanently “anchoring” the entire building to prevent displacement or overturning.

If you would like to learn more about anchoring solutions, please click on “how to anchor a prefabricated house to the foundation?“

Our container Office building Design Process: Collaborative & Efficient

At K-home, we believe a great modular building starts with a seamless and transparent design process. We’ve refined our workflow to ensure your vision is transformed into a buildable, efficient, and cost-effective design through close collaboration.

Step 1: In-Depth Needs Discovery & Consultation

It all starts with a conversation. You’ll work directly with our project managers to define your project’s core requirements, ensuring we build a solid foundation for the design.

Key Details We’ll Define Together:

- Basic parameter requirements: Specify the expected number of floors of the office building (e.g., single-story/double-story), total construction area, site size constraints, etc.

- Functional area planning: Clearly state the requirements for setting up various functional areas, such as the number of workstations in the office area, the size of meeting rooms, and whether independent corridors, pantries, storage rooms, restrooms, etc., are needed.

Step 2: Initial Design & Feasibility Analysis

Our design team takes your requirements and applies our modular expertise. We don’t just create a layout; we ensure it is optimized for manufacturing, structural integrity, and cost-efficiency.

What You’ll Receive:

- A preliminary layout design, delivered within 2-3 business days.

- Initial feedback on the feasibility of complex design elements.

Step 3: Collaborative Review & Refinement

This is where your input shapes the final design. We actively incorporate your feedback on layout, aesthetics, and details. We will continuously refine the design based on your recommendations until you are 100% satisfied. Furthermore, our team will provide expert technical guidance (such as structural feasibility) to ensure a smooth production phase.

Step 4: Final Design Approval & Project Handover

Once the design is finalized and approved, we prepare all necessary technical documents for a seamless handover to our production team, setting the stage for manufacturing. The Final list:

- A complete set of client-approved technical drawings.

- A firm project timeline and cost structure.

Ready to Start Your Project?

Contact a K-home project manager today for a free initial consultation and quote.

Why K-HOME is Your Trusted Partner for Modular Construction?

Technology

K-home draws on its long-standing experience in exporting to countries across Southeast Asia, Africa, Europe, and the Americas—its products have been tested in diverse and complex environments, ensuring reliable performance:

Structural Resilience: It meets Grade 7 earthquake resistance standards; windproof measures adopt high-strength bolt reinforcement and foundation embedded part fixing techniques; waterproofing is achieved through sealed joint treatment of components, all ensuring long-term durability.

Efficient Construction: The “factory prefabrication + on-site assembly” model is adopted. Modular components are precisely processed in workshops, and on-site work only involves splicing and assembly. This shortens the construction period by over 40% compared to traditional methods, significantly boosting building efficiency.

Service

K-HOME implements a dedicated multi-department collaboration model to avoid communication gaps:

1. Sales managers handle demand communication to ensure client needs are accurately captured;

2. The design team focuses on proposal optimization to refine solutions based on feedback;

3. Production and logistics departments follow up on implementation progress.

From initial demand confirmation to proposal adjustments, the entire process is responded to efficiently. Moreover, K-home offers end-to-end “production-transportation-installation” services: the transportation link is overseen by dedicated personnel, with anti-collision packaging used, and cargo status is tracked throughout to ensure components are delivered intact.

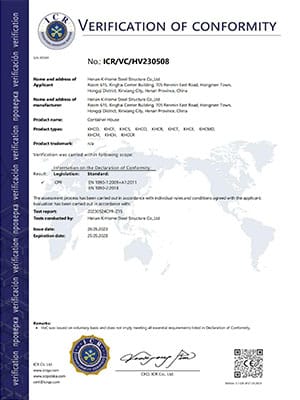

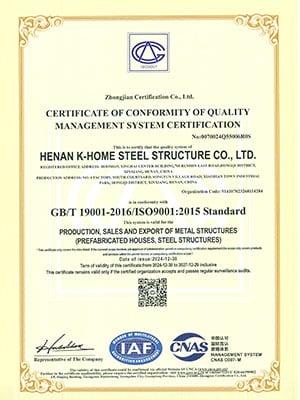

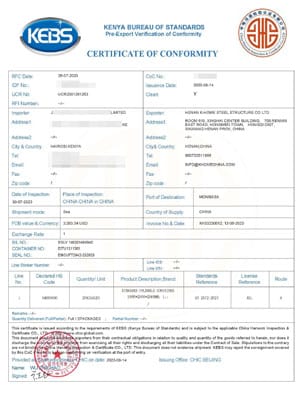

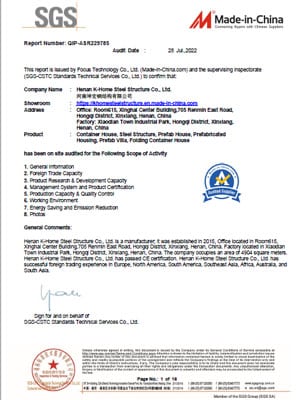

CE certification fireproof standard ISO certification NATA certification PVOC certification SGS certification

Full Installation Support

Installation also comes with complete peace of mind: After cargo delivery, K-home provides a full set of detailed installation materials, including drawings, procedures, and precautions. If clients have needs, professional technicians can also be sent to the site for assembly guidance, solving installation problems hands-on and completely eliminating client concerns.

Comprehensive Certifications

We uphold the highest standards. Behind every building is a rigorous commitment to safety, quality, and sustainability, backed by dozens of internationally recognized certifications.

Ready to Experience the K-home Difference?

Let’s discuss your project requirements and how our proven process can deliver a high-quality, cost-effective modular solution for you.

Our Projects

For more than 15 years, K-home has focused on providing long-term affordable, practical, and efficient on-site space management solutions

in the form of prefabricated worker housing, prefabricated offices, camp buildings, temporary schools, isolated hospitals, etc.

Frequently Asked Questions

SEND A MESSAGE