Folding Container House for mining camp in Indonesia

foldable container house / fold out container house / collapsible container house / Mobile Folding House

Folding Container House for mining camp in Indonesia

Product: folding container house

Manufactured by: K-home

Purpose of Use: Living quarters and offices for the Mining Camp

Quantity: 78 sets

Time: 2025

Location: Indonesia

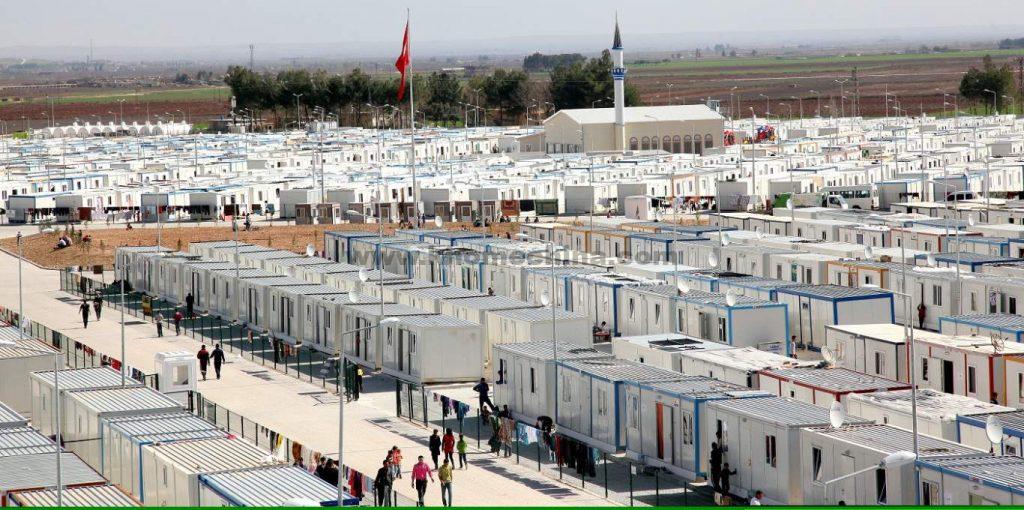

In Southeast Asia’s booming construction industry, a prefabricated container camp in Indonesia stands out for its unique appeal. Containers, as highly flexible modular building units, can be quickly assembled and disassembled to create various functional spaces, such as residential areas, offices, and storage areas, meeting modern construction demands for speed and flexibility.

Prefabricated container camps have many significant advantages over traditional construction models:

- Time Cost: Traditional construction often takes months or even years from foundation construction to main completion, while prefab container camps can complete most construction work in factories in advance, greatly cutting on-site assembly time.

- Space Utilization: Their modular design allows flexible combination according to site conditions and usage needs, maximizing space usage.

- Environmental Protection: Container buildings are reusable, reducing construction waste and aligning with the concept of sustainable development.

Project Confirmation Phase

In November 2024, we received an inquiry from an Indonesian client. They were about to launch a mining project in a remote area and urgently needed temporary housing and office facilities for hundreds of workers and management staff. With a tight project schedule, the client wanted the camp to be set up as quickly as possible to keep it advanced of time.

During initial discussions, the client asked about flat-pack container houses, believing they offered better structural stability for camp use. Through in-depth communication, we found that the client did not know much about flat-pack containers, but only saw them online. To better assess their needs, we asked for more project details as below:

- The mining operation would last 2-3 years, and after resource extraction, the camp needed to be relocated to the next site, requiring frequent disassembly and transportation.

- The remote site had limited construction resources, so minimizing on-site work was crucial.

Based on this information, we quickly realized the client’s needs perfectly matched the features of “foldable containers.” We explained to him “Our foldable containers are ideal for projects with short cycles and frequent relocations like yours.”, and also shared some videos to help him visually understand the product.

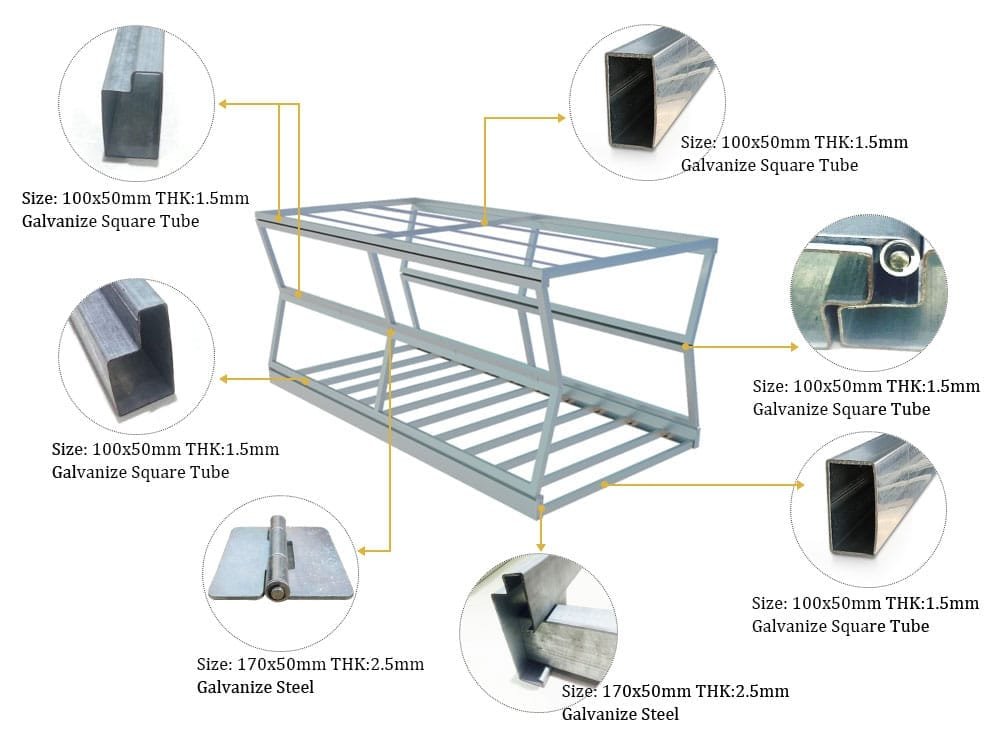

After learning about the product, the client was confused about whether repeated folding and unfolding weaken the structure over time. Our folding container is made of high-strength steel and undergo special processing. Even after multiple disassembled, it will not affect the structural strength. They come in three grades: Basic, Standard, and Premium, the premium type offers superior materials and durability. Considering the camp’s purpose and frequent disassembly needs, the client happily chose the premium type, laying a solid foundation for follow-up cooperation.

In a similar overseas project, foldable containers saved 15 days in setup time, proving their efficiency for tight schedules. This gave our client confidence in their choice.

mining container camp Design Process

Once the client shares their ideas, we start a customized design process. The design team comprehensively balances factors such as aesthetics, practicality, and safety based on their basic information. Through scientific planning and layout, we tailor the most ideal and cost-effective solution for each client.

- Initial Design

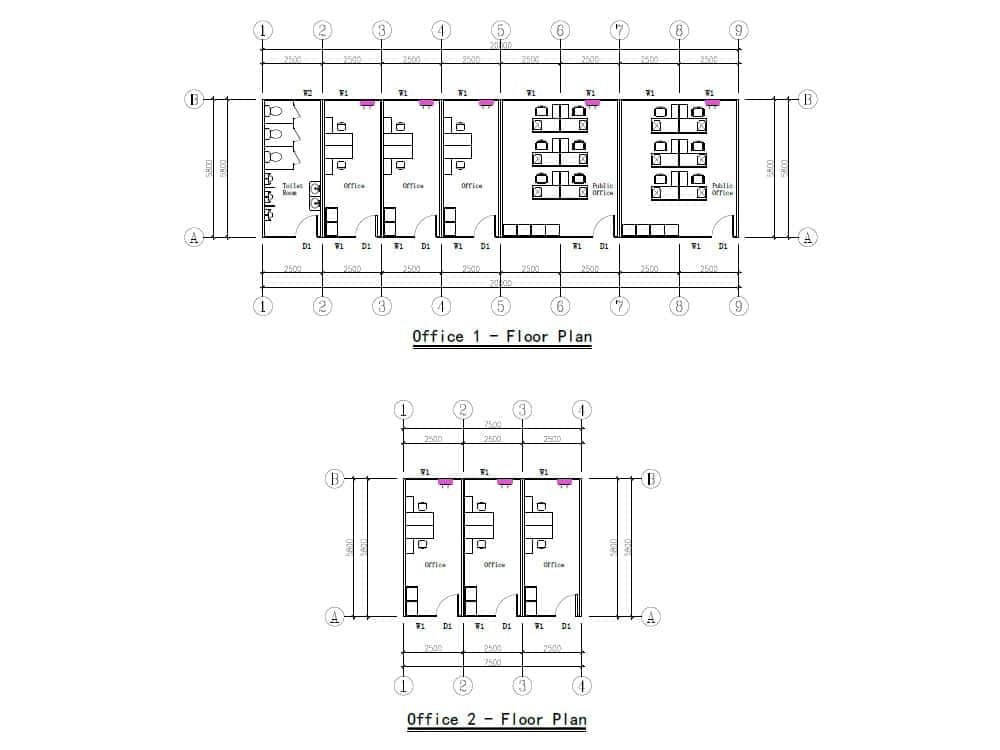

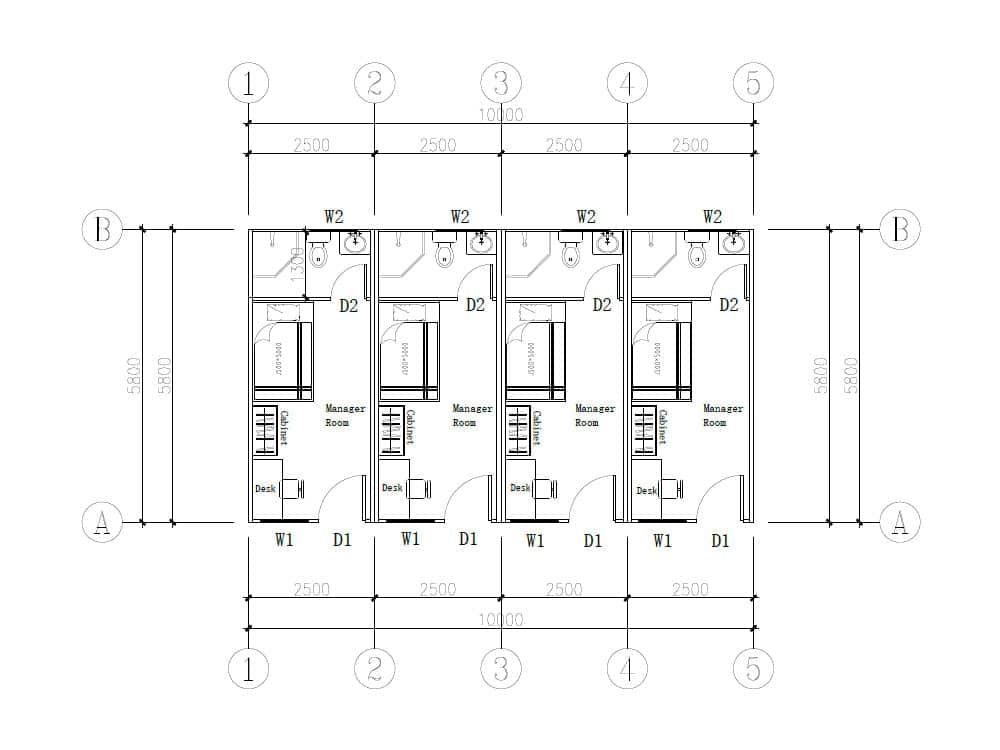

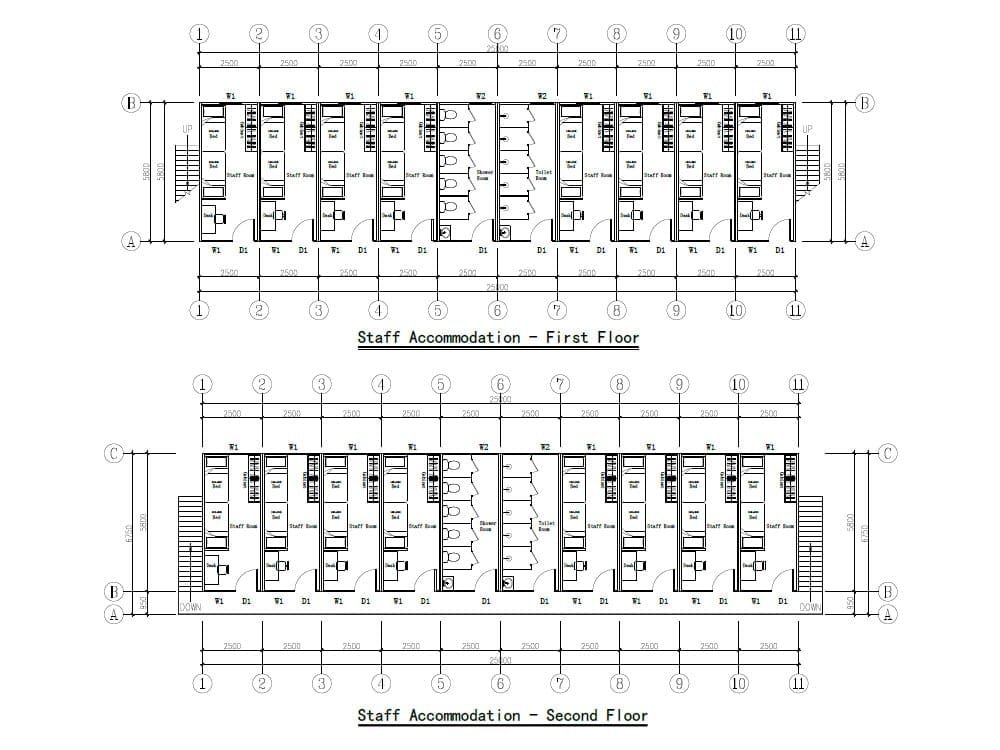

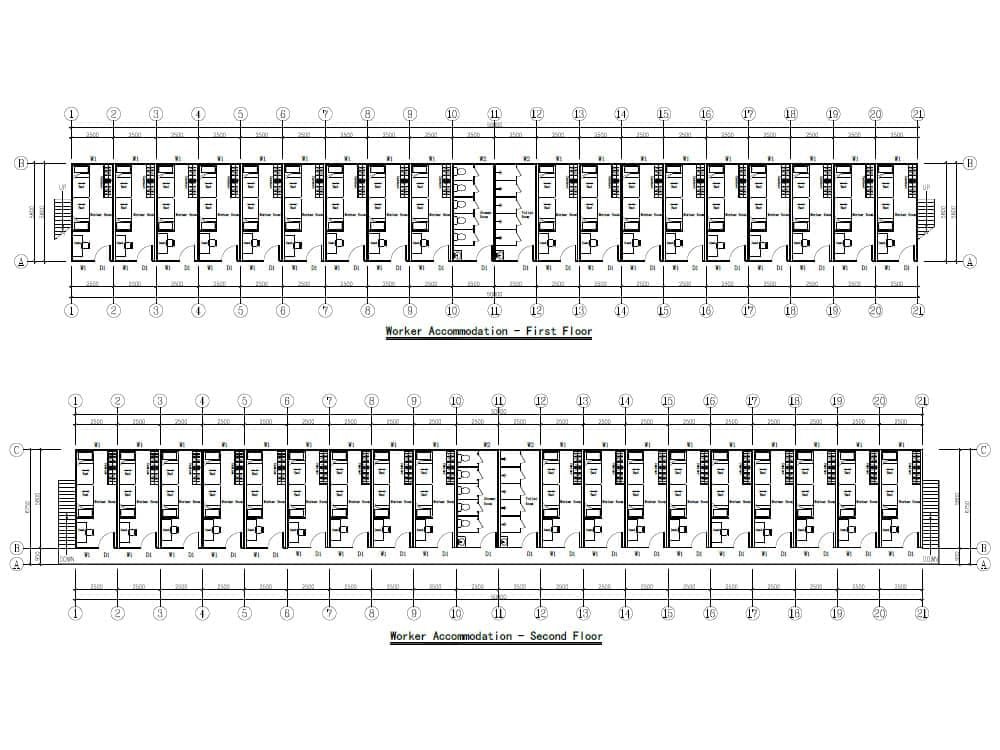

After confirming the container type, the client provided specific architectural requirements: the camp needed to include 5 zones, including a management dormitory building with private bathrooms, two-story 2-person staff dormitories, two-story 2-person worker dormitories, and 2 office buildings. Our design team quickly responded, completed the initial design based on these needs, and sent these design drawings to the client for review.

- Design Revisions

After reviewing the initial design, the client gained a clearer vision of the zone layouts and proposed specific adjustments: changing the worker dormitories to single-story and relocating the public bathrooms. We immediately updated the design according to the client’s feedback and resubmitted it for confirmation.

- Final Approval

Through multiple rounds of detailed communication and layout revisions, both parties finally confirmed the drawings for each building. This process fully reflects K-Home’s customer-centric service philosophy, ensuring the design perfectly matches the client’s expectations.

- Conclusion

In the building construction process, drawing confirmation is often a time-consuming and labor-intensive key step. However, with K-Home, clients don’t need to worry about this. Our professional sales and technical teams will follow up throughout the process, serving as a solid backup for clients to easily obtain their ideal architectural designs.

container camp design floor plan for Indonesia’s client

container office floor plan manager accommoddation floor plan staff accommodation floor plan worker accommodation floor plan

Confirming Housing Supporting Facilities

When purchasing housing, foreign clients typically hope suppliers can provide supporting fittings. This is because they are unfamiliar with the domestic market, and it would take them a lot of time and effort to source and compare each facility themselves. At K-Home we work with carefully selected facility suppliers, who offer high-quality products at competitive prices, meeting diverse project needs.

Different projects require different supporting facilities:

- Dorms usually need beds, mattresses, wardrobes, and bathroom fixtures.

- Offices require desks, office chairs, and filing cabinets.

- Dining areas need kitchen cabinets, ovens, refrigerators, etc.

- In hot climates, air conditioning is a must-have for many clients.

For this Indonesian project, the client requested dormitory furniture and bathroom fittings including beds, mattresses, toilets, sinks, showers, exhaust fans, and AC units. After we sent the specifications and HS codes of these fittings to them, some materials were banned for import in Indonesia. We ultimately provided steel beds, palm fiber mattresses, PVC partitions for bathrooms, and stainless shower sets—meeting the client’s needs while complying with local regulations.

Quotation and Contract Signing

After finalizing all configurations, we prepared a detailed quotation. After careful review, the client approved both the solution and budget, and requested a proforma invoice and contract. We promptly responded and received the client’s deposit shortly after, laying the foundation for smooth project progress.

Production and Shipping

Upon receiving the deposit, we immediately initiated production as below procedures:

- Confirmed final production drawings

- Commenced manufacturing

- Shared product photos for client approval before the balance payment

- Arranged CIF shipping after final payment

Before loading at the factory, we double-checked all items and optimized container space to ensure cost-effective, damage-free delivery.

Construction Phase

Before the goods arrived at the port, our technical team completed detailed installation drawings and manuals to provide clear guidance for every installation step. If the client has issues during installation, we offer remote technical support, fully safeguarding construction progress and quality. We aim to create a worry-free construction experience, helping clients complete their projects efficiently and put them into use quickly.

Main Features of Folding Containers

1. Fast Installation

The whole body of foldable containers are fabricated well in the factory. On-site installation only requires lifting them up and tightening with bolts. 5 minutes can finish a unit. Compared with traditional construction, the on-site installation time of foldable containers can be reduced by 70%-80%.

2. Convenient Transportation

Each foldable container house is three-dimensionally packaged with high-strength PE film to form a 360° dust and moisture barrier to ensure zero loss of the product during transportation. After folding, the volume of the house can be compressed to 1/5 of the unfolded state. This is one of the advantages of foldable container houses. After packaging, they are carefully loaded into containers.

A 40-foot shipping container can efficiently transfer 10 foldable container house units. The characteristics of foldable container houses improve space utilization and reduce transportation costs.

3. Easy On-Site Storage and Management

Construction sites are often newly developed open areas where loose items are prone to loss. The securely packed of folding units makes them much easier to store and manage. In past projects, using foldable cabins reduced on-site item loss rates by over 80%, significantly minimizing unnecessary losses.

Folding Container House Cost

The cost of folding container houses is affected by a variety of factors, mainly including:

- Size and Spatial Layout

- Materials and Construction Specifications

- Interior Configuration and Additional Options

- Procurement Quantity

- Logistics Costs

To develop an accurate total cost budget, you need to consider the base ex-factory price alongside the variables across the five key dimensions mentioned above. Each factor can significantly impact the final investment.

You can click [folding container house prices&cost analysis] to learn more about the cost and full breakdown of folding containers.

Why choose K-HOME folding container houses for mining camp?

As an integrated manufacturer of industry and trade, K-Home reduces the intermediate links through direct production and supply,

minimizing clients’ procurement costs. We always maintain strict quality control from materials to after-sales, ensuring clients receive high-quality products and comprehensive services.

As a national operator with over 15+ years’ experience in the construction industry, K-Home has found an excellent balance between product quality and affordability. Whether for small temporary camps or large site construction projects, our prefabricated modular units can meet the needs excellently. Let K-Home turn your construction vision into reality. Contact us anytime!

K-HOME’s prefabricated container house series

Related Project

Related Articles

SEND A MESSAGE