Prefabricated Camp Building: Cost-effective & Reliable Solutions for Remote Sites

As a leading supplier of prefabricated camp buildings, we provide durable K-type & T-type modular units for mining, construction & emergency camps.

For project leaders in mining, large-scale infrastructure, and other similar sectors, setting up a durable, rapidly deployable, and cost-controlled temporary camp is often a key challenge to project success.

Prefabricated camp buildings meet this challenge head-on. They transform the long, unpredictable timelines of traditional construction into efficient, precise, modular manufacturing. This shift enables rapid on-site deployment, flexible expansion, and reliable performance even in the most demanding environments.

At K-HOME, we specialize in high-performance camp solutions for the mining, energy, and infrastructure sectors. We understand that a reliable camp is more than just accommodation—it’s a foundation for personnel safety, morale, and project efficiency. That’s why we deliver more than just K-type and T-type houses. We provide a rapid-response system encompassing planning, production, and installation, ensuring your camp construction integrates seamlessly with your project timeline.

- prefab modular camp(by k house)

- Construction Site Temporary House(by k house)

- Worker Accommodation Camp

- prefabricated camp(by T house)

- construction camp building(by T house)

- prefabricated labor camp(by T house)

- prefabricated mining camp(by T house)

- prefabricated mining camp(by T house)

Prefabricated Camp Building: KHOME’s K House and T House Solutions

As a professional supplier of prefabricated camps, K-HOME offers container camp buildings and prefabricated camp buildings. This article primarily introduces our prefabricated campsite solutions. Our prefabricated campsites feature two main house structures: K-type and T-type, to meet the diverse needs of different clients.Both structures are factory prefabricated and assembled on-site, but they have different focuses in design concepts, load-bearing performance and application scenarios, which can meet the needs of various camp construction projects.

prefab K House: An Economical & Practical Standardized Solution

Prefabricated K House is an economical and practical prefabricated camp building structure launched by KHOME, known for its standardized design and rapid assembly capabilities.

This structure uses a light steel frame, combined with prefabricated wall panels, roof panels and floor modules. Most of the production processes are completed in the factory, and then transported to the site for assembly.

K House is usually suitable for projects with high requirements for construction period and cost control, such as temporary construction camps or disaster shelters.

prefab T House: A Robust and Durable Enhanced Structural System

Prefab T-type House is an enhanced prefabricated camp building structure designed by KHOME to meet more complex environmental conditions and higher usage requirements.

Compared with K House, T House has significantly improved load-bearing capacity, spatial span and durability, making it suitable for harsh weather conditions or long-term use scenarios.

Prefab T House is more suitable for semi-permanent camps, such as mining living areas, field research bases.

Understanding the core differences in prefabricated camp construction methods | How to choose?

In the planning and construction of prefabricated buildings for camps, structural design is the core factor that determines the building’s performance, applicable scenarios, and long-term value. The KHOME provided K-house and T-house solutions have developed based on two distinct structural. These two structures are not merely an upgrade relationship but rather product systems developed in parallel to meet differentiated demands. Different design concepts.

Ⅰ. Structure Design

K-House: Lightweight, standardized, and highly efficient modular design

The structural design of K House adheres to the core of “lightweight, standardization, and high efficiency”. Its design intention is to address project scenarios that require rapid deployment, are cost-sensitive, and have relatively flexible usage cycles.

In the structural system, K-House adopts a light cold-formed, thin-walled steel structure as the main load-bearing framework. This framework features lightweight components with cross-sections, formed through precise cold-bending processing, which significantly reduces the self-weight of the materials while ensuring the necessary strength.

The entire structural system is broken down into highly standardized panel modules, such as frames, wall panels, roof panels, and floor. Each module is prefabricated in the factory, greatly simplifying the on-site construction process and enabling rapid construction.

Its structural logic pursues economic optimization under the given standard loads (such as conventional wind loads and snow loads), with all designs aiming for repeatability, batch production and rapid turnover.

T House: Heavy-duty, Customized and High-tolerance Frame Design

In contrast, the structural design of the T House adheres to the engineering concept of “heavy-duty, customized, and high-tolerance”. It is targeted at long-term camps that have higher requirements for building lifespan, environmental adaptability, and spatial quality.

The T House adopts a heavy-duty frame structure mainly composed of square steel tubes. The beams and columns of this frame have larger cross-sections and significantly thicker steel, thus forming a strong and robust main skeleton. The design logic is to first establish a solid “spatial skeleton” that can withstand large variable loads, and then fill in the enclosure walls, floor slabs and other components. Therefore, the structure of the T House is closer to that of traditional permanent houses, emphasizing the integrity and anti-deformation ability of the structure.

It allows for larger spatial spans (such as column-free large open spaces) and can safely support multi-story construction. The design focus is on enhancing structural redundancy and using higher-performance materials to cope with complex and harsh application environments and provide extensive customization possibilities for customers.

Ⅱ. Main structure and connection technology

prefab k house

The main frame of a karaoke room is a lightweight skeleton.

Its columns and top and bottom rails are typically made of thin-walled C-shaped or U-shaped steel. They are tightly connected to the wall panel joists using self-tapping screws or special clips. This connection method is efficient and economical.

prefab t house

The main frame of the T-shaped building is a robust steel square tube skeleton. Its steel columns and beams are typically connected rigidly or semi-rigidly using welding or high-strength bolts to form a stable portal steel frame. This connection method provides strength and stiffness far exceeding that of lightweight systems, effectively resisting structural deformation caused by uneven settlement, strong winds, and earthquakes.

Ⅲ. Enclosure system and insulation integration

For the enclosure system, both use composite sandwich panels, but the integration methods and performance grades are different.

- The wall panels of K House are usually integrated modules that serve as both load-bearing and enclosure. The panels and internal studs are pre-combined in the factory, with the insulation core material (such as rock wool, glass wool) completely enclosed within. On-site, only the entire panel needs to be fixed to the frame. This “sandwich” panel.

- The enclosure panels of the T room mainly serve as non-load-bearing filling components, suspended or fixed on the main steel frame. As they do not participate in the main force-bearing, they can adopt thicker insulation layers (such as core panels over 100mm) and achieve more complex exterior wall construction layers (such as external decorative layers, etc.), thereby obtaining excellent thermal insulation, sound insulation and moisture-proof performance.

Prefabricated K-type house wall panel installation Prefabricated K-type house wall panel installation Prefabricated T-type house wall panel installation Prefabricated T-type house wall panel installation

Ⅳ. Load-bearing capacity and spatial freedom

- K house: The clear span of a single floor in K-rooms is usually limited by the performance of lightweight materials, typically ranging from 6 to 12 meters. It is suitable for standard functional units such as dormitories, offices, and convenience stores. The number of floors is mainly single, and occasionally, a lightweight two-story structure can be designed.

- T house: With its heavy-duty frame, the T House can easily create a column-free single-story space of over 12 meters, making it possible to meet the large-space requirements of canteens, meeting rooms, warehouses, maintenance workshops, etc. Its structure can stably support vertical construction of up to two floors, greatly enhancing land utilization and the functional complexity of the camp.

Ⅴ. Economic and Flexibility Spectrum

From a full life cycle cost analysis, K House has an absolute advantage in initial investment and short-term usage costs. Its high standardization brings about a scale effect that lowers the unit price, and its lightweight design saves on transportation and foundation costs. T House has a higher initial investment, but over a usage period of more than ten years, its outstanding durability, low maintenance costs, and excellent energy efficiency (due to better insulation) will spread out the initial cost, demonstrating higher long-term value.

Temporary Camp Building Applications | Completed Cases

The true test of any building solution is its performance in real-world conditions. Across diverse industries and environments, Khome’s prefabricated building systems have consistently provided the durable, adaptable, and rapid-deployment capabilities our clients count on. Discover our proven track record through the selected applications and case studies highlighted here.

remote mining camp ( prefab canteen& training) in tanzania

Project Requirements: Provided safe and durable prefabricated canteen & training rooms for remote mining operations.

Core Challenges:

• The building features a large-span, column-free structure; heavy machinery could not be used during on-site installation.

• The concrete floor has been poured, which restricts the building’s structure.

• The project is on a tight schedule and requires rapid construction.

Solutions & Key Achievements:

• Customized prefabricated T-shaped building system, fully meeting the needs for large spaces, safety, and durability

• Completed all installation and delivery within 12 days

Construction camp in malaysia

Project Requirements: Two custom-made prefabricated office buildings (each 11×5m).

Core Challenges:

• Heavy rainfall and high humidity climate

• Ensure rapid installation to meet project deadlines

Solutions & Key Achievements:

• Successfully completed the design and construction of prefabricated offices, meeting waterproofing and moisture-proof requirements.

• Installation Guarantee: Chinese engineers provide on-site, hands-on guidance to ensure structural stability and zero errors.

prefabricated workforce housing in malaysia

Project Requirements: Workforce Housing for 150 personnel(Services included design, manufacturing, and logistics support from China to Malaysia)

Core Challenges:

• Maintaining a balance between product quality and budget

• Use materials adapted to the climates of Malaysia

Solutions & Key Achievements:

• Utilized K-type prefabricated modular building structure.

• Successfully completed logistics and final delivery integration in Malaysia.

Prefabricated Camp Building Supplier KHOME | Why choose us?

In the highly competitive prefabricated camp building market, KHOME has established a significant advantage through its comprehensive strength and customer-oriented philosophy.

From product innovation, project delivery to after-sales service, KHOME is always committed to providing reliable, efficient and sustainable camp solutions for its customers, and has become a long-term partner of many industry leaders.

High-quality product guarantee

KHOME has an independently developed design team and production system, continuously optimizing the structural techniques and material applications of K-houses and T houses. By using high-strength steel, environmentally friendly insulation boards and anti-corrosion coatings, it ensures the safety and durability of the buildings in various environments.

Customizable Layouts & Configurations

KHOME supports deep customization services, and can adjust the size of the houses, facade styles and internal configurations according to the specific functional requirements, brand image or local regulations of the customers, providing truly tailor-made prefabricated panel house camp solutions.

Full lifecycle service

From consultation and design, factory prefabrication to on-site installation, KHOME implements full-cycle project management to ensure precise connection at each stage.

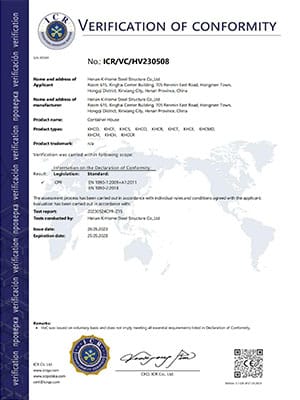

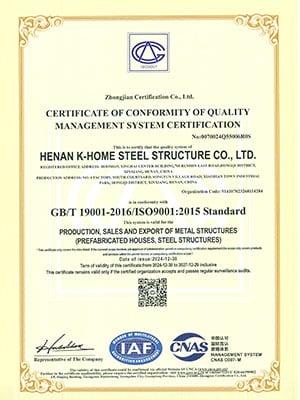

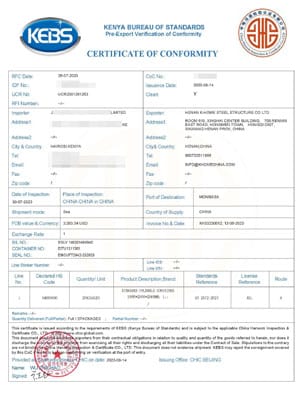

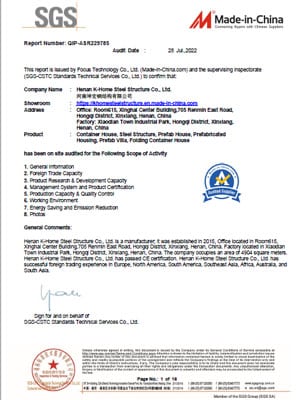

Comprehensive Certifications

We uphold the highest standards. Behind every building is a rigorous commitment to safety, quality, and sustainability, backed by dozens of internationally recognized certifications.

Related Project

Related Articles

Frequently Asked Questions

SEND A MESSAGE