Rapid Deployment of Prefabricated Canteen & Training Rooms for a Remote Mining Camp in Tanzania | k-HOME case study

As Tanzania continues to expand its mining sector, the demand for practical, efficient, and rapidly deployable mining building solutions has increased significantly.

One of our recent projects involved supporting a mining extraction company that was establishing a large-scale camp for its workforce. The client required two essential buildings, a staff dining hall and a training classroom to ensure employees could complete mandatory training and begin field operations without delay.

This case study presents the background, challenges, customized solutions, project outcomes, and customer feedback regarding the prefabricated T-type building system we provided.

prefabricated canteen & training rooms in Tanzania | project overview

| PPRJECT INFORMATION | PROJECT PERFORMANCE |

| Client: Mining extraction company in Tanzania | Key Outcomes: Provided safe and durable prefabricated canteen & training rooms for remote mining operations. |

| Project Scope: • Supply staff dining hall (200 sqm) and training classroom (180 sqm). • Services included design, manufacturing, and logistics support from China to Tanzania. | Key Achievements: • Customized prefabricated T-shaped building system, fully meeting the needs for large spaces, safety, and durability • Completed all installation and delivery within 12 days |

| Core Challenges: • The building features a large-span, column-free structure; heavy machinery could not be used during on-site installation. • The concrete floor has been poured, which restricts the building’s structure. • The project is on a tight schedule and requires rapid construction. | Quality & Compliance: • All products meet quality standards • Ensure low maintenance costs and long service life. |

| Solutions: Customized prefabricated T-type building system based on structural calculations | Progress and Customer Feedback: Installation finished, customer satisfaction 100% |

From Demand to Delivery: An In-Depth Analysis of Remote Mining Camps in Tanzania

Ⅰ. Project Background and Requirements

The client, a mining extraction firm operating in a remote region of Tanzania, was in the process of developing a full-service workers’ camp to support the launch of a new mining operation. As part of the initial phase, they urgently needed two key facilities:

- A 200-square-meter prefabricated canteen to accommodate daily meal service for employees.

- A 180-square-meter prefabricated training classroom where staff could complete operational, safety, and procedural training before entering the mining plant.

Because these two functions were prerequisites for employees to begin site work, the company required a solution that could be deployed immediately, achieve rapid assembly, and maintain structural reliability under the specific site conditions.

Ⅱ. Core challenges: Multidimensional delivery barriers

Infrastructure limitations in remote mining areas are often a decisive factor in project success or failure. Due to the camp’s distance from towns, weak infrastructure, limited supply chain, and scarcity of lifting equipment, extremely high demands are placed on suppliers.

In this project, a tight schedule and intense bidding pressure coexisted. We understand that only suppliers who can break through industry limits in areas such as technological innovation, logistical adaptation, and cost control can stand out from the competition. Based on this, we specifically analyzed and addressed the following six pain points:

1. Requirement for Rapid Deployment

The workforce needed to be mobilized quickly. Any delay in constructing the dining hall and training classroom would directly affect the operational schedule of the entire mining project. The client required a building system that enabled extremely fast installation without compromising quality.

2. Remote Location with Limited Logistics

Transporting conventional building materials to the remote mining site posed considerable difficulty. Heavy steel structures, large pre-assembled modules, and bulky components were impractical due to road limitations and high logistics costs.

3. No Heavy Lifting Equipment Available On-Site

The project site lacked cranes and other heavy lifting machinery. Therefore, the buildings had to be installable entirely by manual labor or with minimal lightweight tools.

4. Existing Concrete Ground Without Embedded Anchor Bolts

The ground had already been completed with concrete slabs, but no embedded foundation bolts were prepared. This condition prohibited many traditional steel structures that require pre-embedded anchoring systems to support columns and primary frames.

5. Large Interior Spans Without Columns

The client specified that both the dining hall and classroom must have wide, open interior spaces without intermediate columns, which posed an engineering challenge for achieving structural strength while keeping logistics lightweight.

6. Custom Dimensions and Budget Constraints

Because the client was working under a competitive bidding system, they required fully customized building dimensions at the lowest feasible cost, without reducing performance or durability. Only a solution that balanced cost, speed, and customization would be accepted.

Ⅲ. Our Solution: High-Customization Prefabricated T-Type Buildings

To address all of the client’s concerns, we proposed a fully customized prefabricated T-type housing system, designed specifically for remote deployment.

1. Tailor-Made Design and Structural Engineering

Based on the client’s specific needs, a T-shaped building system was ultimately chosen. This system allows for large-span, column-free spaces. Through adjustments to the building dimensions, internal layout, and span, a suitable design was created for both an open-plan dining hall and training classrooms.

2. Component-Based Transport for Remote Areas

Unlike general steel structures or other modular construction, T-type buildings utilize lightweight steel frames and modular transportation methods, offering the following advantages:

- High loading and unloading efficiency

- Significantly reduced transportation costs

- Perfectly adaptable to remote and narrow road conditions

- Components can be easily handled manually

3. Installation Without Heavy Machinery

The key advantage of our T-type system is that all installation operations can be done manually. The lightweight components attach with standardized fasteners and pre-designed connection points, eliminating the need for cranes or forklifts.

4. Direct Installation on Existing Concrete Surface

The buildings were engineered to be installed directly on the existing concrete ground without embedding additional anchor bolts. This eliminated the need for secondary civil work and significantly reduced construction time.

5. Cost Optimization

Prefabricated T-type structures offer a significant cost advantage. Their unit price is approximately $60 per square meter, exceeding the client’s cost-effectiveness expectations and maintaining their competitiveness in the bidding process.

The combination of modular components and simplified installation procedures drastically reduced on-site labor hours and allowed the client to meet their critical deadlines.

prefabricated canteen elevation drawing prefabricated canteen floor plan prefabricated canteen steel frame layout prefabricated training room Elevation drawing prefabricated training room floor plan prefabricated training room – steel frame layout

Ⅳ. Project results: Efficient delivery of 380㎡ building within 12 days

With the detailed installation drawings and technical guidance we provided, the client, with a junior construction team of only 10 people, completely completed the construction of a total of 380 square meters in just 12 days.

- Significantly ahead of schedule: Both buildings were completed ahead of schedule and put into immediate use. This “delivery-to-operation” efficiency allowed the mining company to begin employee training and catering services earlier.

- Structural safety and spatial efficiency in harmony: The use of a light steel panel house (Prefab T-house) not only ensured structural safety for the large-span space with a column-free design, but also significantly reduced on-site installation labor costs through standardized node design.

Ⅴ. Client Feedback

After the project was completed and put into use, the client gave it high praise, highlighting the following advantages:

- Rapid construction ensured timely staff arrival.

- The canteen ensured stable catering services for staff.

- Training classrooms supported timely training and onboarding of new employees.

- Structural quality and functional design exceeded expectations.

The client clearly stated that the prefabricated T-shaped building system would be a cost-effective solution for their future camp expansion and planned to actively recommend our company to their business partners.

Why choose K-home as your partner for mining camp?

As a professional temporary building manufacturer, K-HOME is committed to providing you with safe, efficient, and multifunctional mining camp solutions.

K-HOME always prioritizes product quality and customer needs. From initial customized design to final installation, we rigorously control every step to ensure our prefabricated buildings exceed the highest industry standards in durability, safety, and sustainability. Our high standards guarantee that every prefabricated building is durable enough to withstand the test of time and various natural elements.

Committed to Creative Problem Solving

We tailor each modular building to your needs with the most professional, efficient and economical design.

Buy direct from the manufacturer

Modular prefabricated buildings come from the source factory, carefully selected high-quality materials to ensure quality and durability. Factory direct delivery allows you to get prefab building at the best price.

Customer-centric service concept

We always work with customers with a people-oriented concept to understand not only what they want to build, but also what they want to achieve.

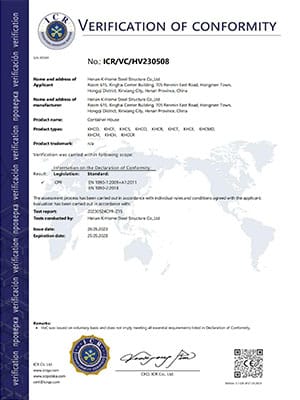

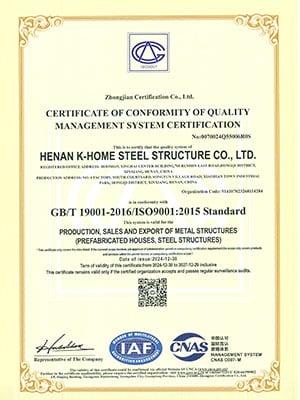

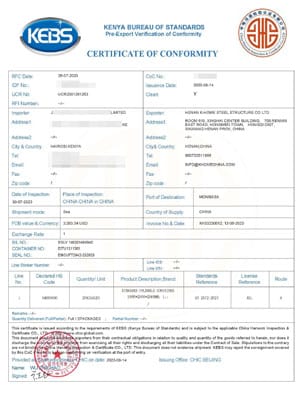

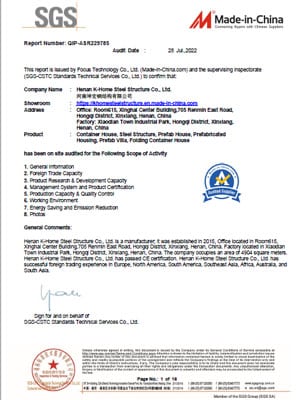

Comprehensive Certifications

We uphold the highest standards. Behind every building is a rigorous commitment to safety, quality, and sustainability, backed by dozens of internationally recognized certifications.

To learn more about our offerings, discover how we can tailor a solution to suit your specific requirements, or to schedule a consultation, please don’t hesitate to reach out to us. Our friendly team is always ready to assist you and guide.

Frequently Asked Questions

Related Project

Related Articles

SEND A MESSAGE