prefab labor camp

modular labor camp / prefabricated worker camp / prefab labor colony / labor accommodation camps / man camp housing

Construction and industry is one of the most dynamic sectors. They need to build efficient and economical labour housing. Prefab labour camps can be used as temporary living and working spaces and provide the necessary infrastructure for workers.

Prefabricated labour camps are favoured by industries such as construction, mining and oil and gas. They are usually established in remote or challenging areas. Prefabricated labour camps can be built for a variety of needs such as offices, dormitories, kitchens, dining halls, and more.

Modular container houses are used as one of the solutions for prefabricated camps. They can be erected in just a few weeks, replacing traditional temporary housing and meeting the needs of fast-track projects. The efficiency of these modern labour camps lies in their modular design. Each containerised housing unit is built to exact specifications in the factory, which not only ensures uniform quality, but also eliminates the possibility of weather-related construction delays. Once shipped to the site, the units can be assembled into complete living complexes qurters, including bedrooms, bathrooms, dining rooms and offices, in a very short period of time.

What is a Prefabricated Labor Camp?

Prefabricated labour camps are also known as prefabricated labour quarters and prefabricated labour colonies. They are places set up for all employees on construction sites or in remote areas. The site can cater for the varying needs of the employees and must also meet strict safety and health standards.

These camps can provide infrastructure, safety and a well-equipped living environment away from the city. Our modular site camps are designed to withstand harsh conditions. They can be easily configured to support projects of all sizes. K-HOME is an expert in the production of labour camps based on modular structures and prefabricated buildings. Our prefabricated modular buildings can be designed for different sectors such as construction sites, public works, mining, military camps or emergency situations. Our team can provide customisable and reliable solutions with professional experience and dedication to quality.

Why Container Houses Are Ideal for Modular Workforce Housing?

When setting up workforce housing, container houses offer clear advantages that make them the smart choice. Here’s why more companies are choosing this solution:

Speed Matters Most

Time is money on any project. Traditional construction can take months, but a container house camp can be ready in weeks. The units arrive pre-built, so assembly is quick and simple. No waiting for concrete to dry or dealing with weather delays. Your workers can move in faster, and your project can start sooner.

Built to Last

These aren’t flimsy temporary structures. Made from heavy-duty steel, container houses stand up to tough conditions. They handle extreme heat, freezing cold, heavy rain, and strong winds with ease. The sturdy construction also resists wear and tear from daily use, meaning they’ll last through your entire project – and many more after that.

Grow As You Go

Projects change, and your housing should too. Need to add 20 more workers next month? Just drop in more container units. Finished with one site? Pack them up and move to the next location. This flexibility saves money and hassle compared to permanent buildings.

Budget Friendly

Between faster setup, reusable units, and lower maintenance, container camps save money at every step. There’s no need for expensive foundations or complicated construction. The savings add up quickly, especially for short-to-medium term projects.

From remote mining sites to urban construction projects, container house labor camps deliver where it counts. They provide the right mix of durability, comfort and flexibility that modern projects demand – all while keeping costs under control. It’s no wonder they’re becoming the go-to solution for companies worldwide.

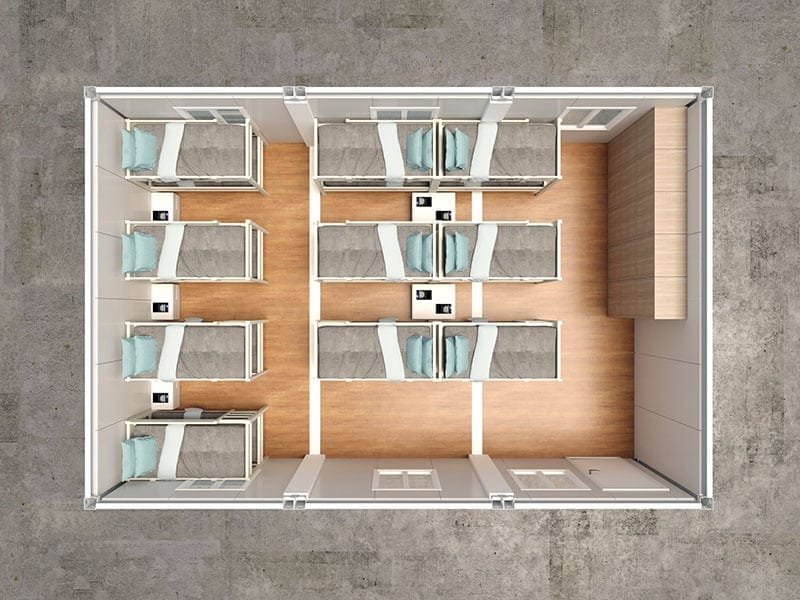

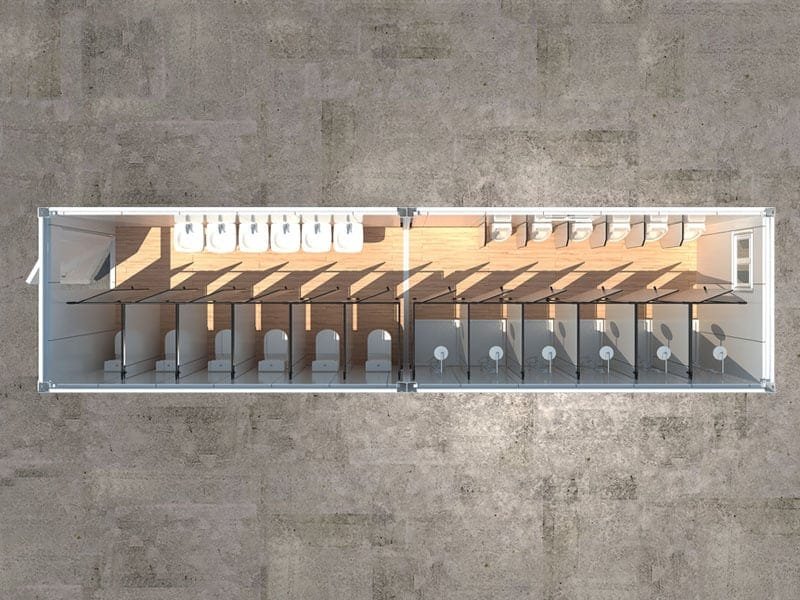

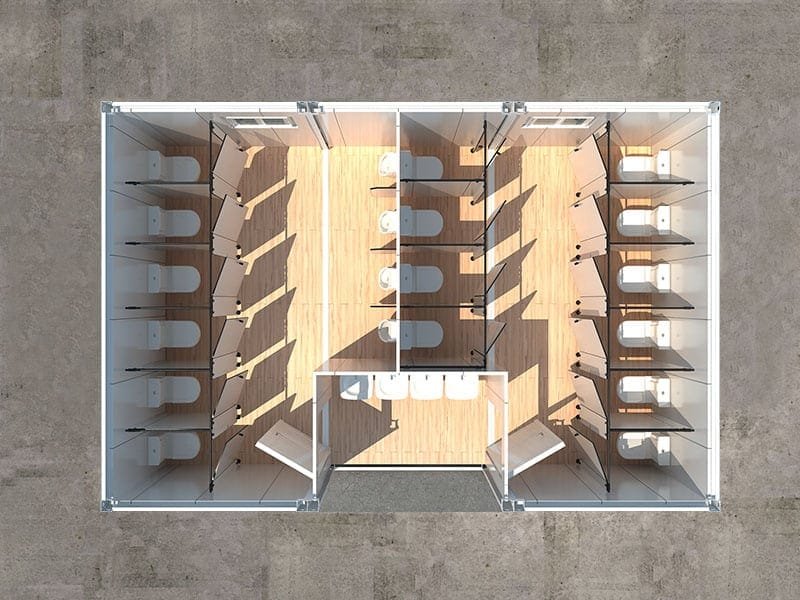

prefabricated container labor camp layout plan

The layout of the prefabricated labor camp is designed according to the function of use. Different areas are reasonably divided according to functional requirements to ensure efficient and synergistic operation of each block. The layout of the camp is based on the actual number of users, using containerized housing units as the carrier, and configuring functional modules such as accommodation, office, catering and leisure to form an integrated and comprehensive living area.

The advantage of using container units to create a modular camp is: the container units can be freely combined according to the scale of the project. They can not only meet the basic needs, but also can be expanded according to the special requirements of more detailed functional partitions, such as independent bathrooms, meeting areas or storage space. The design of modular labor camps takes into account both practicality and expandability, enabling rapid construction and adjustment through standardized modules, while optimizing space utilization to ensure personnel living comfort and working convenience.

K-HOME is committed to designing customized workforce housing that meets your needs. Our final solutions will take into account project budgets, usage habits, and industry norms to create modern, cost-effective, and fully functional prefab labor camps.

usage areas of Prefabricated labor camps | Customized for various projects

From construction sites to disaster zones, prefab labor camps provide flexible housing solutions across industries. Their quick deployment and durability make them ideal for:

- Construction camp – Providing temporary housing for workers on construction sites. These container units can be quickly erected. Compared with traditional buildings, they can save costs and enable projects to be put into operation quickly.

- Mining & oilfield – Perfect for housing workers at remote job sites. Units install quickly near work areas and relocate easily when projects end.

- Emergency Response – Disaster relief teams deploy these camps immediately after earthquakes or floods, providing safe temporary shelter with basic amenities.

- Student housing – These prefabricated labor camps are built as temporary dormitories to meet students’ temporary housing needs when student population surges or schools are undergoing renovations.

- Military – The armed forces value them for secure field housing during missions.

- Special Events – Event organizers utilize them for comfortable staff accommodations that are more practical than tents or hotels.

The secret to their versatility? Three key advantages: rapid setup (often in days), rugged steel construction, and easy customization. Whether needed for weeks or years, these mobile camps deliver quality housing wherever required – no permanent foundations needed. Their adaptability continues to create new applications across different sectors.

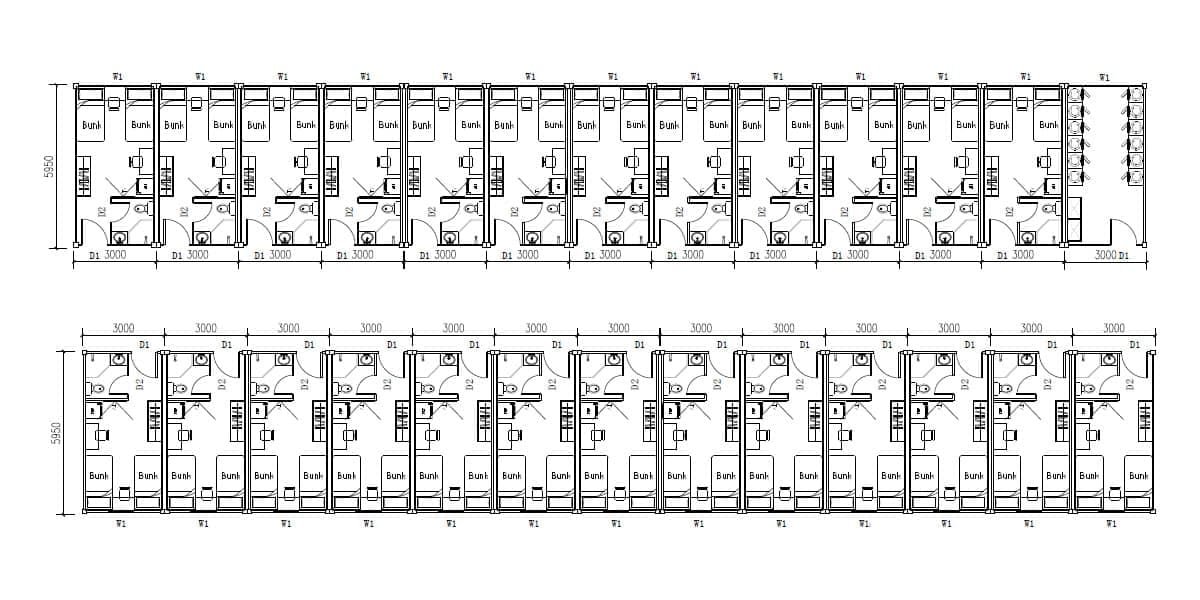

Specifications for modular prefab labor camp | container camp unit

All of our modular and prefabricated labor camps are manufactured remotely and transported to the site for assembly and use. The size and interior decoration may vary depending on the purpose and your requirements. The following are the general technical specifications for prefabricated construction site campsite buildings:

- Size: We provide various offices, dormitories, changing rooms, cafeteria containers, and sanitary buildings for labor camps. They come in standard sizes and can also be customized according to your requirements.

- Structure: The structure of prefabricated containers is made of high-quality galvanized steel. Unlike the container units on the market, the bottom structure of K-HOME’s container has been upgraded. We use more square tubes for support to ensure that the bottom of the house has a high-strength support effect. At the same time, we have set up downpipes inside the columns to ensure that rainwater can flow out smoothly without causing water leakage in the house. In addition, we also support the customization of the frame structure. You can increase the frame thickness, strength, and change the frame structure to meet your unique project needs.

- Wall: sandwich panel wall with insulation material thickness up to 100mm, including rock wool, polystyrene foam or polyurethane.

- Roofing: Most prefabricated construction sites use insulation boards and galvanized steel roofs.

- Windows: Aluminum alloy or PVC frame double-layer glass windows are standard. Optional sliding windows and outward windows can be installed, and the material can be upgraded to bridge cut aluminum. Other customization options include anti-theft railings, blinds, mosquito nets, alarms, and other security facilities.

- Door: You can choose steel, aluminum or PVC fireproof doors, and anti-theft railings and safety measures can be provided according to requirements.

- Option: The structure and interior space of the building we built for the prefabricated labor camp can be modified in various ways. According to the size and purpose of the building, the internal layout can be modified, open and enclosed spaces or other facilities can be added, and external wrapping can be carried out.

Example of solution: 100-person containerized prefabricated labour camp solution

The layout design of the prefabricated labor camp needs to take into account the office, accommodation and catering needs of the management staff and workers. All designs and plans should ensure proper functional zoning. Accommodation units are standardized in containers with a maximum of 8 persons per unit. In the actual design, the specific number of people can be flexibly adjusted according to the project budget, space comfort or the normative requirements of different countries, and the client can independently customize the number of people to be accommodated. The remaining functional areas (e.g. office area, cafeteria, bathroom, etc.) will be scientifically planned according to the actual number of users and daily needs. All space planning optimizes space utilization while meeting basic functions.

In addition, the design of the container accommodation camp focuses on practicality and humanization. Through the modular combination to achieve rapid deployment, and set aside the possibility of expansion. At the same time, it should meet the needs of project scale changes or later adjustments. K-HOME’s aim is to design efficient, comfortable, and standardized campsite solutions.

Here is a detailed plan for a 100 person container prefabrication camp, covering key elements such as layout design, footprint, and production cycle, for your reference:

Container Camp design floor plan

1、Accommodation area (60% area):

- 25 standard accommodation containers + 1 shared Laundry room (20-foot containers, 3m x 6m) / Double Room Configuration (4 people/unit, 100 people in total), Each container accommodation unit includes an independent bathroom, air conditioning, beds, and storage cabinets.

2、Public area (30% area)

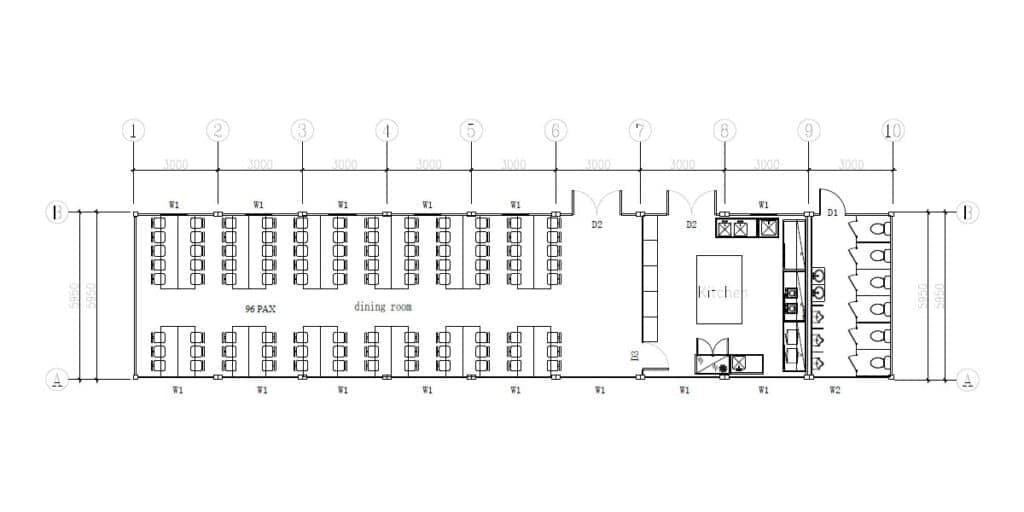

- Restaurant/Kitchen: 8*20 foot containers (able to accommodate 96 people dining at the same time)

- Recreation room: 4*20-foot containers (TV, table, and chairs)

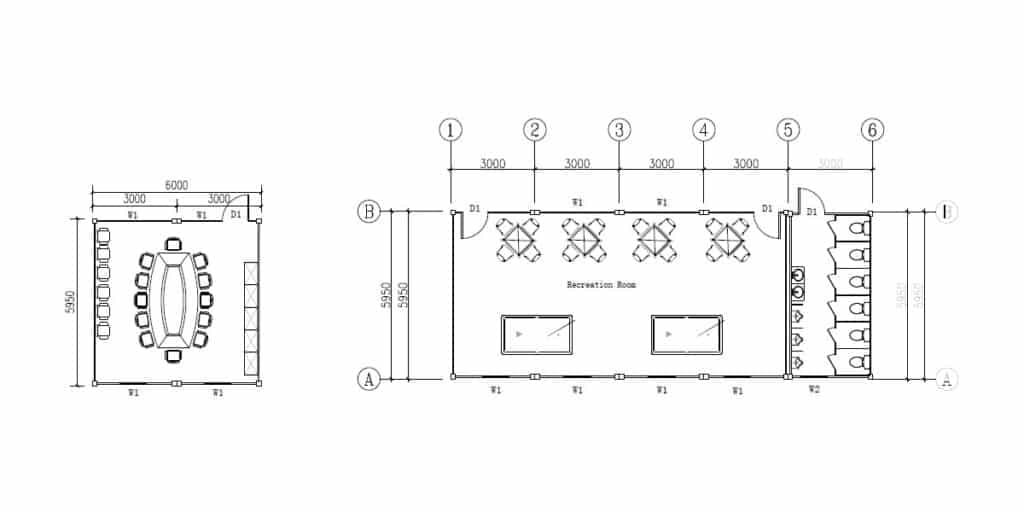

- Meeting room: 2*20-foot containers (foldable partitions)

- Toilet (supplement): 2*20ft containers (scattered layout)

prefab labor camp – staff accommodation floor plan

prefab labor camp – dining room for 96 preson floor plan prefab labor camp – meeting room & recreation room floor plan

Area calculations for container camp design

Single container occupation (including spacing):

- 20 ft container unit: 3m x 6m+perimeter spacing ≈ 30 ㎡/unit

Total area:

- Accommodation area: 26 units x 30 ㎡=780 ㎡

- Public area: 14 units x 30 ㎡=420 ㎡

- Approximately 1200 square meters in total

Note: An additional 10% -15% buffer zone is required, and it is recommended to use 1380 square meters of land

Estimated production and delivery cycle

Production time: 15-20 working days

Shipping time: To the Middle East/Africa: 30-40 days;To Europe: 45-50 days

If further optimization of the plan is needed, the configuration can be adjusted according to specific needs such as climate conditions and service life.

case studies of Workforce Housing solutions

As the world’s leading modular workforce housing solution supplier, we focus on creating efficient and comfortable prefab labor camps for all kinds of engineering projects. With rich industry experience, we have successfully delivered hundreds of containerized camp projects for customers in more than 30 countries. These regions around the world, covering a wide range of fields such as energy, mining and infrastructure. Each project is individually designed according to the actual needs of the client, from basic accommodation to integrated living quarters, from temporary housing to long-term residency, we can provide optimal solutions.

Labour camp accommodation in Mali

construction camp in Ghana

Other ways to build prefabricated labor camps

Prefabricated container units are the mainstream choice for the prefabricated worker camps due to their portability, but they are not the only option. Based on the actual needs of the project, we also offer a variety of construction options such as lightweight steel prefabricated houses. These prefabricated houses are modular in design and expandable using modular T/K, they are also rapidly deployable and can be adapted to most geographic environments.

Our professional team will recommend the optimal form of construction based on key factors such as project cycle, budget size, and climatic conditions, ensuring a safe and comfortable living environment for workers while controlling costs. Years of project experience have proven that a diverse range of solutions tailored to local conditions often lead to better project results.

China prefab labor camp manufacturer, supplier

K-HOME is a leading manufacturer of prefab labor camp, famous for its innovation and excellence in the industry. With an unwavering commitment to quality and customer satisfaction, K-HOME designs and produces workforce housing solutions that are both durable and versatile. Our houses are built with the best craftsmanship to meet many needs of modern life. They also offer a sustainable and cost-effective alternative to traditional houses. As a trusted leader in the market, K-HOME keeps pushing the limits of container homes, bringing great value and quality to customers worldwide.

Besides, our promise of customer happiness doesn’t just end when you first buy the container unit. We offer full support to help you with any problems or worries, from installation guides to fixing technical issues. Our after-sales services include maintenance support, repairs, and possible upgrades, making sure your unit meets your needs for a long time. Our dedicated team is always ready to help, ensuring your experience with our container dormitory units is positive and worry-free.

SEND A MESSAGE