Full Range of Prefab Buildings for Remote Camps

K-HOME offers durable prefabricated canp buildings for mining & oil &construction camps

With 15+ years of design experience, k-home can provide All-in-One Prefab Camp Building solutions.

Overcoming the Top Challenges of Remote Camp Development

Setting up an efficient and safe camp in a remote area is no simple construction project. It requires balancing three key elements: environmental durability, budget, and timeline.

We understand the real pressures you face. Based on our experience, successful camp construction means overcoming some core challenges:

- Coping with Harsh Environments and Climates: Whether it’s the scorching heat of the desert, the humid climate of the tropics, or the corrosive salt fog of the coast, your campsite structures must withstand the test. They need to provide reliable shelter, ensure the safety of personnel, and offer fully functional living and working spaces to support the well-being and productivity of the team.

- Controlling Costs: Frankly, cost is often the deciding factor. Every part of the budget is crucial. From initial construction investment and transportation to on-site installation, all of this needs careful planning and optimization to ensure the project is financially sound from start to finish.

- Meeting Speed Needs: Tight project schedules mean delays directly increase costs. Traditional on-site construction methods are slow and unpredictable. When you need to quickly set up and put a campsite into use, this approach simply cannot meet your needs.

So, what’s the solution?

These challenges have made prefabricated modular construction the preferred solution for remote camps. Construction is no longer carried out in uncontrollable on-site conditions, but rather in a controlled, efficient factory environment.

This is precisely where K-HOME excels. We focus on providing engineered, ready-to-use prefabricated construction solutions designed to systematically address these challenges, helping you build a robust and reliable camp from the outset.

K-HOME Solutions: Our Prefab Solutions for Remote Camps

There is no one-size-fits-all solution to these challenges. A successful labor camp requires precise configuration for different functions. This is where K-HOME’s value lies: we offer a full range of prefabricated camp building solutions: prefab container camps, and prefabricated camp building. You can choose one or more to configure the optimal solution for every functional area of your camp.

Functional Area 1: Worker & staff Accommodation Solutions

Providing safe, comfortable, and rapidly scalable accommodation for teams working in remote areas is fundamental to the success of a camp. K-HOME offers two proven prefabricated accommodation solutions to meet the diverse needs of everyone from management to workers.

prefab container accommodation

When project timelines are tight, staff sizes are variable, or rapid phased deployment is required, container accommodation solutions are the best choice.

So, how do prefabricated containers meet accommodation camp needs?

- They support from private 1-2 person management suites to large-scale dormitories for 50-200 people, dynamically adjustable according to personnel composition.

- Independent bathrooms can be integrated within each unit, greatly enhancing convenience and privacy, suitable for projects with specific accommodation standards.

- Container houses have a modular structure and a high degree of standardization, enabling rapid on-site installation and deployment.

low-cost k-type modular dormitories

K-type house is the most cost-effective temporary workforce housing choice when your project has the following characteristics:

- Short-term or temporary accommodation needs (e.g., project cycles of 1-3 years).

- Strict budget control is a key decision-making factor.

- The need to quickly accommodate a large number of people, with no special requirements for high customization.

Its core advantage is very clear: achieving the lowest possible investment cost per person while meeting basic accommodation needs.

We achieve this through mature, standardized, and modular design. This avoids the additional costs and time associated with non-standard customization, allowing you to obtain a clear and controllable total investment budget from the beginning of your project.

Unsure which option is best suited to your project size and budget?

Functional Area 2: Office and Command Center Solutions

Our various prefabricated systems can meet the design needs of camp office spaces. They all allow for customized spatial layouts and designs based on their existing structures, whether it’s a shared workspace or a separate manager’s office area.

- When a project requires a rapidly buildable and highly mobile office, prefabricated containers are the preferred solution.

- When a project needs to establish a cost-optimized office area with high space utilization, K-type buildings are an ideal choice.

- When a project requires a large, accessible space that meets the requirements of harsh environments, T-type houses are an ideal choice. They can increase the use of steel to withstand rain and snow loads, while providing spacious, column-free interiors and more flexible layouts.

- office container cabin

- Private Office

- Portable Construction Site Office Cabin

- Container Office

- prefab k house for staff office

- prefab k house for staff office

- prefab T house for staff Office

- prefab T house for Meeting Room

Functional Area 3: Prefab canteen & dining room Solutions

If there are no special requirements for the canteen layout, any prefabricated solution can be chosen based on the needs. From a cost-effectiveness perspective, the K-house will be less expensive. If a large space with a column-free design is required, both the K-house and T-house can meet the needs.

Functional Area 4: Sanitation Facility Solutions

Planning toilets for remote campsites hinges on a reliable and easy-to-implement water and drainage system. K-HOME’s prefabricated solutions systematize this complex process, ensuring smooth deployment and stable operation through professional pre-planning.

Containerized toilet units offer flexible layouts, and drainage solutions can be customized to project conditions.

- Wall-mounted drainage: Minimal foundation requirements, making it the most adaptable standard solution.

- Floor drainage: We offer matching column-supported raised foundation designs.

Toilet spaces can be integrated into accommodation units to form private bathrooms, or multiple units can be connected to quickly create a centralized communal bathroom area.

K-type house bathroom modules offer strong structural integrity and can be used as fixed large bathroom areas.

This structure is based on a monolithic concrete slab foundation and typically employs reliable wall-mounted drainage. If the project requires traditional floor drainage, raised foundation treatment within the modules must be completed during construction.

Regardless of the product chosen, we provide a complete set of technical solutions, from foundation design to drainage selection, minimizing on-site construction uncertainties.

Technical Comparison: Container vs. K-Type vs. T-Type

Understanding the core features and applicable scenarios of each product line can help you make more accurate decisions. Below is a comparison of our three main product lines across key dimensions:

| ITEM | Container Unit | K-Type Buildings | T-Type Buildings |

| Core positioning | Frequent Relocations & Flexible Customized | Cost-effective & Quickly Assembled | Spacious & Column-free Space |

| Initial Budget | Medium ★★★★☆ | Low ★★★☆☆ | Medium ★★★★☆ |

| Construction Speed | ★★★☆☆ | ★★★★☆ | ★★★★☆ |

| Customized Flexibility | ★★★★★ | ★★★☆☆ | ★★★★★ |

| Foundation | No foundation or custom foundation | Concrete slab foundation | Concrete slab foundation |

| Application Scenario | Construction sites, oil field and mining camps, as well as projects that require phased construction, camps that require flexible expansion capabilities, and camps that require frequent relocation. | Large-scale employee dormitories, centralized office and living areas, and short- to medium-term projects with tight budgets and fixed cycles. For example: construction camp | This type of camp requires spacious, barrier-free space and high customization flexibility. It is commonly used in remote oil and gas extraction camps, mining camps, etc. |

Why choose K-HOME as your prefab camp building partner?

In workforce camp construction, true reliability comes not only from blueprints and materials, but also from real-world testing in complex environments.

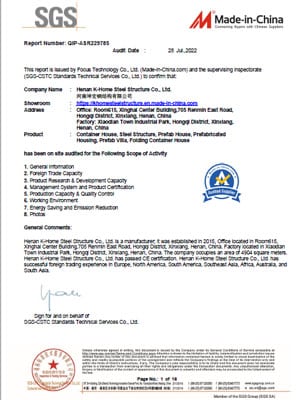

K-HOME is not just a manufacturer, but a participant in the prefabricated camp industry. Our value lies in understanding your specific challenges and transforming them into success time and again through proven prefabricated solutions.

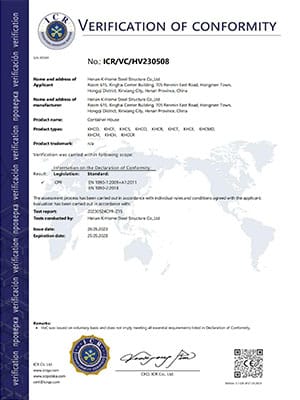

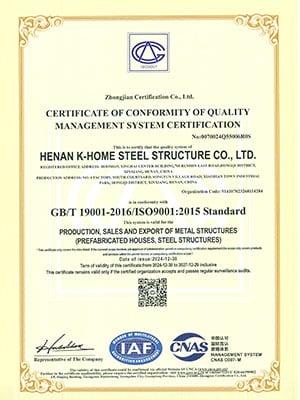

Quality is the Foundation: Based on Standards, Exceeding Standards

We understand that for projects operating in harsh environments, quality is the bottom line that cannot be compromised. Therefore, K-HOME’s production and quality control system is built on dual standards:

- A rigorous internal quality control system: Adhering to industry standards is just our starting point. To ensure real-world reliability, we’ve implemented a strict internal quality control system. This means we have clear checkpoints at every single stage—from inspecting raw materials to delivering the finished module. This ensures that every module leaving the factory can withstand long-distance transportation and on-site testing.

- Authoritative industry certifications: Our products comply with ISO 9001 quality management system standards and have obtained CE certification. But our focus on standards doesn’t stop there. Our designs and materials also meet key national standards and are engineered to satisfy the strict camp construction requirements in markets like Europe, the Americas, and Australia.

Customized prefab camp solutions for different industries | Case studies completed

To date, K-HOME’s prefabricated camp buildings have been successfully implemented in numerous countries and regions worldwide. These include African markets such as Mozambique, Guyana, Tanzania, Kenya, and Ghana; the Middle East regions such as the UAE and Saudi Arabia; South American countries such as Brazil and Peru; and Asian countries such as the Philippines, Malaysia, Laos, and Indonesia. We are familiar with diverse climatic conditions and specific needs, enabling us to provide you with integrated labor camp solutions that combine safety, durability, and economy, facilitating the smooth construction of your projects.

Labour accommodation camp in Mali

When you choose K-HOME, you’re not just embarking on a procurement process, but on a partnership focused on your project’s success. We’ll work closely with your engineering team, intervening from the early planning stages to ensure seamless integration of architectural designs with your site plans, logistics, and operational processes. Our committed delivery timelines are rigid because we understand that getting your project started on time is paramount.

How K-HOME Helps Clients Select the Right Prefab Building for Camp?

At K-HOME, we understand that selecting a Prefab Building for a camp is a strategic decision that affects project efficiency, workforce satisfaction, and operating costs. Our team supports clients through a structured selection process.

Step 1: Define Camp Functions and Occupancy Requirements

Khome works with clients to identify required functions such as sleeping accommodation, offices, toilets, showers, dining halls, kitchens, medical rooms, and storage areas. Projects with complex functional needs benefit from prefab modular systems, which allow easier integration of utilities.

Step 2: Align Building Type with Project Duration and Budget

For short- to medium-term projects, container houses provide a practical Prefab Building for Camp solution with controlled costs. For long-term projects or camps intended for repeated reuse, prefab modular buildings deliver better lifecycle value and energy efficiency.

Step 3: Assess Site Conditions and Transportation Logistics

Remote locations, limited infrastructure, or overseas shipping often favor container-based solutions. Khome engineers evaluate logistics conditions to ensure the selected Prefab Building for Camp system minimizes transportation and installation costs.

Step 4: Optimize Installation Time and On-Site Work

All Khome prefab buildings are factory-produced, allowing interior finishes, electrical systems, and sanitary installations to be completed before delivery. This reduces on-site labor, shortens installation time, and ensures consistent quality.

Step 5: Ensure Compliance with Local Standards

Khome designs each Prefab Building for Camp according to applicable building codes, fire safety requirements, and insulation standards. This ensures suitability for both temporary and semi-permanent camp use.

Step 6: Plan for Reuse, Relocation, and Sustainability

Khome prefab solutions are designed for dismantling and reuse, helping clients reduce waste and improve sustainability performance across multiple projects.

Related Articles

SEND A MESSAGE