Crane Steel Structure

steel crane structure / Steel Structure With Crane / overhead crane steel structure / Crane Supporting Steel Structures

Crane steel structure is a modular building system designed for industrial scenes. It combines high-strength steel with lifting equipment and is widely used in factories, warehouses, ports and other places that require heavy material handling. This type of structure is known for its fast assembly, high load-bearing capacity and flexible scalability, making it the first choice for modern industrial facility construction.

Crane Steel structure and lifting integrated solution | K-HOME PEB building manufacturer

As China’s leading integrated solution provider for crane steel structures and lifting equipment, K-HOME is committed to providing high-quality integrated services to industrial customers. We specialize in designing and building crane steel structures suitable for workshops, warehouses, industrial sheds and other scenes, and provide high-performance bridge crane systems to create complete industrial facility solutions.

In the field of steel structures, we provide two types of structures, heavy and light. With the excellent performance of steel, we can flexibly realize the design of buildings with different spans (especially large spans) to provide customers with economical and efficient construction solutions. At the same time, we are equipped with a professional bridge crane product line to ensure the perfect match between lifting equipment and steel structures.

We have an experienced team of engineers and a complete sales and after-sales service system, providing professional technical support from project planning to implementation. Whether it is steel structure crane buildings or lifting equipment, K-HOME can provide you with reliable one-stop services to help projects advance efficiently. Welcome to contact K-HOME for customized steel building & lifting solutions.

Design type of Steel Structure Building with Overhead Crane System

K-HOME provides you with two professional crane steel building solutions: heavy steel structure and light steel structure, both of which support the integration of crane systems of different tonnages to meet various industrial needs.

Heavy steel structure is designed for the industrial field and is particularly suitable for building high-load industrial plants and large facilities. The structure has a short construction period and can be put into use quickly. At the same time, it has a service life of up to decades, which is an ideal choice for production and processing, warehousing and logistics, distribution centers and other scenarios.

Light steel structure is more suitable for small and medium-sized building needs. While ensuring structural strength, it can significantly reduce the amount of steel used and optimize construction costs. The structure has high space utilization, flexible and controllable building height, and is more economical than traditional building forms.

Whether it is a large industrial plant or a small and medium-sized functional building, K-HOME’s steel structure solution has the advantages of fast construction and reliable quality, and can provide you with professional customized crane steel structure solutions.

crane steel structure type: double-slope single Span

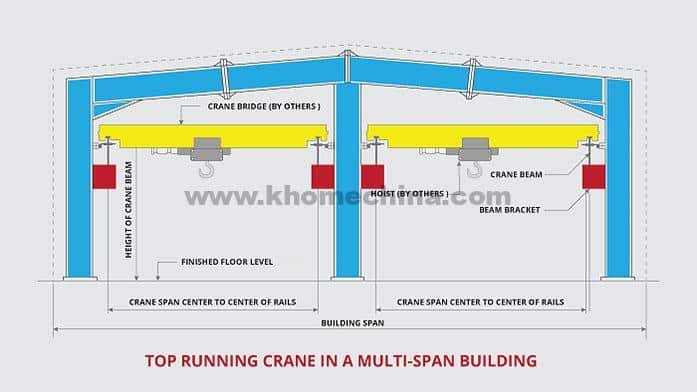

crane system: Bridge overhead cranecrane steel structure type: double-slope double-span

crane system: Bridge overhead cranecrane steel structure type: double-slope single Span

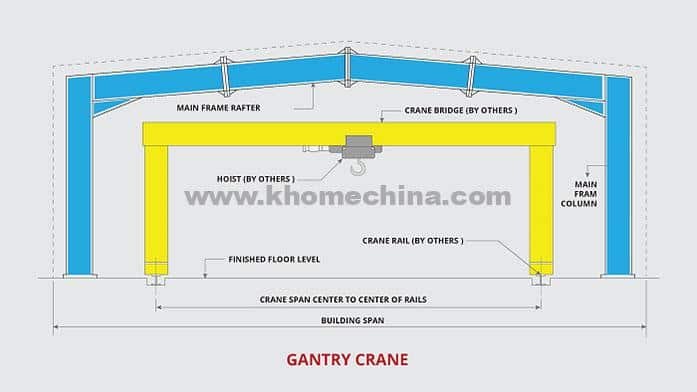

crane system: Gantry crane

- Industrial Steel Crane Buildings

- Steel Workshop Building With Crane

- crane steel building with overhead

- Crane Supporting Steel Structures

- Structural Steel Frame With Crane

- Industrial Steel Crane Buildings

- Peb Steel Crane Building

- steel warehouse with crane

learn more Crane Steel Structure Components

Primary and Secondary Steel Framing

Columns, beams, and trusses make form the primary steel frame, which supports the crane’s vertical and horizontal loads. Because of their excellent load-bearing capability, hot rolled steel sections, such H-beams and I-beams, are frequently utilized in the building of these components. Purlins and wall beams, two secondary steel components, are used to join the outside wall system and main structure, guaranteeing the stability of the building under seismic and wind loads.

Cladding and Optional Features

Corrugated steel sheets or insulated sandwich panels form the exterior cladding, protecting the interior from weather while providing thermal insulation at the same time. For facilities requiring natural light, translucent polycarbonate sheets or fiberglass panels (often called “daylighting panels or FRP”) are installed on the roof. Ventilation systems, such as ridge vents or louvers, maintain airflow to prevent heat buildup in foundries or welding shops.

- Single Tile Roof System

- Single Tile Roof System

- Sandwich Panel Roof System

- Sandwich Panel Roof System

Crane Runway Beams and Rails

Dedicated crane runway beams, usually made of wide-flange steel sections, are anchored to the primary structure to support the crane’s movement. Rails mounted on these beams guide overhead or gantry cranes, ensuring precise load positioning.

Key considerations for integrated design of crane systems and steel structure buildings

When constructing a steel building with an overhead crane, the crane equipment requirements and the building structure must be considered in tandem, rather than separately. It is important to define the requirements for constructing this steel building. This includes: the lifting capacity of the crane, the lifting height, the span, the expected hours of use per day and the purpose of the building. These basic data will have a direct impact on the selection of the crane and the strength design of the steel structure.

1、Crane lifting capacity: The lifting capacity of a crane is the maximum weight that the crane can safely lift. For example, if a crane’s lifting capacity is labelled ‘10 tonnes’, it means that it can lift a maximum of 10 tonnes (including the weight of hooks, ropes and other lifting devices). This directly determines the strength of the steel ‘skeleton’.

It affects the design of the steel structure in terms of the thickness of the steel, the thickness of the steel column cross-section and the depth of the steel foundation. In other words, the design of a steel building needs to take into account the strength of the steel and the amount of steel used.

2、Lifting Height of Crane: The lift height of a crane refers to the vertical distance the crane hook rises from its lowest position (usually near the ground) to its highest position. Simply put, it is how high a crane can lift a load. Lifting height has an impact on the design of the steel structure:

- The clear height of the plant must match. Generally speaking, the height of a steel structure building (from the ground to the roof beam) must be greater than: hoist height + hook height + safety clearance. For example, if the crane lifting height is 10 metres and the hook height is 1 metre, then the clear height of the building must be at least 11.5 metres (10+1+0.5 safety clearance).

- Affect the steel columns and roof structure. The higher the lifting height → the longer the steel column → higher structural stability requirements

- Related to the span.

Overall, it directly affects the plant height, steel structure and overall cost.

3、span of the crane:The span of the crane refers to the horizontal distance between the crane rails, which is simply understood to be the working range that the crane can cover horizontally. Note: The span of the crane needs to be co-ordinated with the span of the building to ensure that the crane can be installed and operated smoothly. For example, if the crane has a span of 20 metres, the span of the building must be able to accommodate at least 20 metres, and often needs to be wider to allow for installation and operation. The span of the crane affects the design of the steel structure in the following ways:

- Influence the column span and the size of the main beams. The larger the span of the crane, the stronger the beams and columns are needed to support it. So when designing the steel structure, we should find the balance point and design the best solution.

- Impact on the runway beam support structure. Runway beams should be made of higher strength materials and reinforced.

- Combine the lifting capacity for linkage calculation. For the same lifting capacity and different spans, the type of steel used will be different.

Therefore, when designing the integration scheme of steel structure and tower crane, multiple factors should be considered at the same time. They are not a number, but a systematic project that affects the whole body.

At K-HOME, we do not recommend that your crane and steel structure design belong to different suppliers. You need a professional supplier to design both the building and the equipment. Only in this way can various compatibility issues be avoided during construction. We have encountered many cases where customers purchased the crane first and then designed the factory building. It turned out that the track installation position conflicted with the building columns, or the steel structure had insufficient bearing capacity and needed to be reworked and reinforced, which not only caused additional costs, but also seriously affected the project’s progress.

This is the value of K-HOME’s integrated solution. You just need to tell us your specific needs. Our professional team will take care of all the complex technical work: from calculating dynamic loads, to optimizing steel structure design, to ensuring the normal operation of the crane. Our goal is to provide you with the most economical and safest crane steel building solution.

Case study – steel structure workshop with 5-ton overhead Crane

Why choose K-HOME crane steel structure buildings?

Choosing a professional PEB building supplier can greatly simplify your workflow. As one of the professional crane steel structure suppliers in China. We provide an integrated solution that integrates the design of steel structure and crane. Ensure that each link is seamlessly connected, avoid common coordination problems, and reduce risks in design and construction.

Our team has rich experience and expertise.They can provide you with the most optimized design solutions. These solutions ensure the strength and stability of the steel structure while meeting all technical requirements for crane operation. We use advanced design software and engineering analysis tools to ensure that every design detail is strictly verified while ensuring the economy and efficiency of the project.

Whether it is a new project or an upgrade of an existing facility, K-HOME can provide customized solutions to meet your specific needs. Contact us to ensure that your project is safe, efficient and economical.

SEND A MESSAGE