Steel Portal Frame Building

There are many types of steel structure buildings, and portal steel structure is one of them. Steel structures built with this structure are called portal steel structures. This form of building is the most common, with a flexible structure that can be built into a single-span or multi-span structure. Its specific construction plan will be professionally customized according to key factors such as the project’s geographical location, climatic conditions, and load requirements.

As China’s leading steel structure building contractor, K-HOME has always been committed to providing customers with one-stop services from design to construction. Our professional steel structure solutions can perfectly adapt to the needs of various building uses. Whether it is a metal warehouse for warehousing, steel storage and freight center, or a machine shop, auto repair shop and steel welding shop as a production site, or even a variety of heavy steel structure buildings, K-HOME can rely on its rich industry experience and technical strength to create safe, reliable, cost-effective and efficient steel structure buildings for customers.

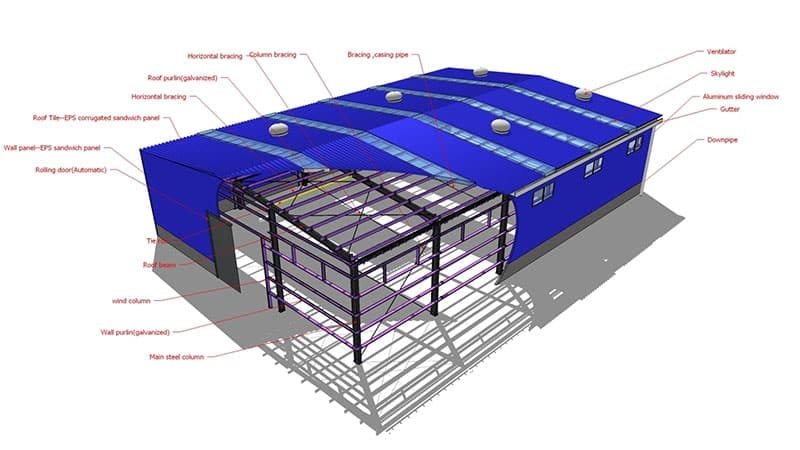

steel portal frame building detail

structural steel portal frame diagram

main structure of steel portal frame building

1、foundation plans for steel building

Columns don’t go straight into the ground. During concrete pouring: Anchor bolts are embedded.After concrete sets, column base plates align with exposed bolts.Workers tighten large nuts to secure the structure.This ensures that the building is firmly fixed to the ground without moving or toppling.

2、Main Frame

The main frame is composed of welded H-shaped steel, which supports the building’s weight and withstands wind/snow loads. It is the core part of the structure.

3、Bolt connection

Beams and columns, beams and beams are connected with high-strength bolts; columns and beams, beams and beams are not welded, but connected with very strong bolts.

This connection method is both firm and reliable, and allows workers to quickly install and adjust on site. It is more convenient and efficient than welding, and is also convenient for possible disassembly in the future.

4、Purlins (Roof & Wall Supports)

On the main frame of the roof and walls, some spaced “small beams” need to be installed, which are called purlins. Purlins are cold-formed, which saves materials, reduces costs, and is light in weight. Their main role is to support and fix the outer wall/roof panels, and transfer the loads to the main frame.

5、Wall & Roof Options

The walls and roof use colored corrugated steel sheets or insulated sandwich panels, which are connected to the purlins with self-drilling screws. This forms the building’s enclosure system, providing functions such as wind and rain protection, thermal insulation, etc.

6、Flexible Doors & Windows

The selection of doors and windows is very flexible, depending on client’s needs and budget:

• UPVC: Made of high-strength plastic steel, good insulation, affordable, and not easy to rust.

• Aluminum alloy: Lightweight and strong, not easy to deform, with a modern appearance and good durability.

• Light steel: The frame is made of very thin steel, extremely strong and durable, with good fire resistance.

The size, style, and color of both doors and windows can be customized. Just reserve openings at the installation position.

Why choose portal steel structure?

Clear Span Structure:

Steel allows for clear span construction, meaning no load-bearing walls or columns are needed to support the roof—the steel frame alone is strong enough. The clear span design allows for a building width of 30 to 36 meters, with no columns obstructing the space.

Customizable:

At K-Home, we provide standard-sized construction drawings for steel portal frame buildings in various lengths, widths, and heights. However, as mentioned, our prefabricated warehouses are customizable—if you need more space than our standard kits offer, our design team can create drawings for you.

Cost-Effective:

Steel portal frame kits offer some of the best cost savings in construction—pricing starts at USD45/m² and tops out at USD120/m², tailored to your needs. Since all materials are prefabricated, there are no construction site delays—every frame component fits perfectly, as do the steel plates for walls and ceilings.

Easy to Construct:

Materials used by K-Home for prefabricated steel structure buildings are quickly formed, cut, and welded. All materials can arrive at the site within weeks, speeding up construction.

Other Benefits:

Environmentally friendly, structurally robust, earthquake-resistant, waterproof, and energy-efficient.

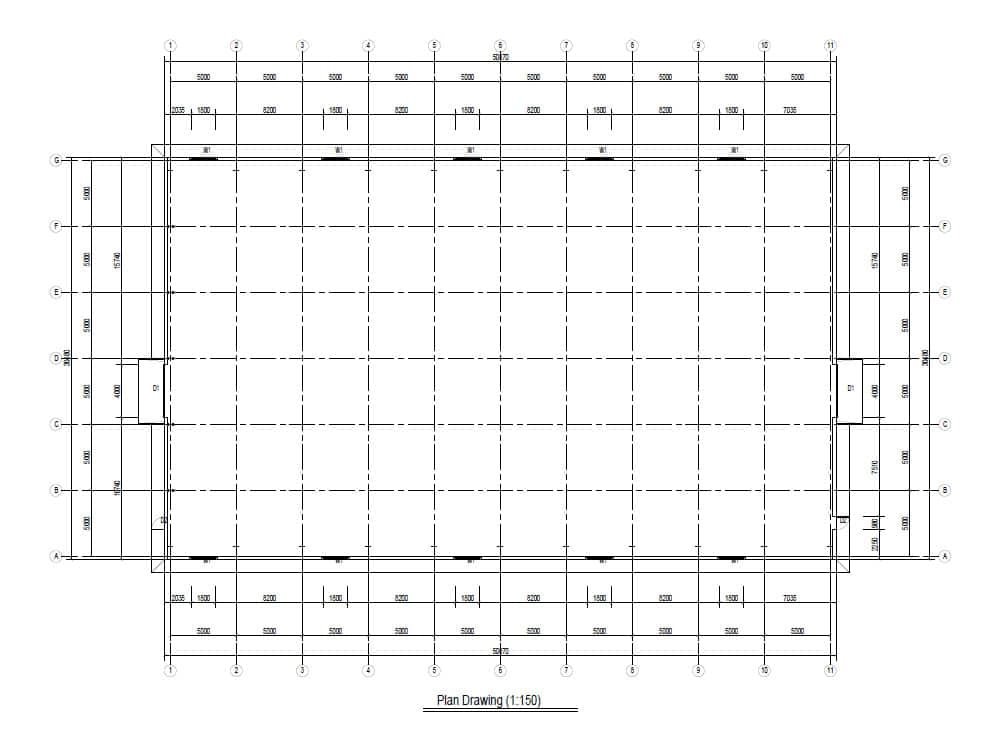

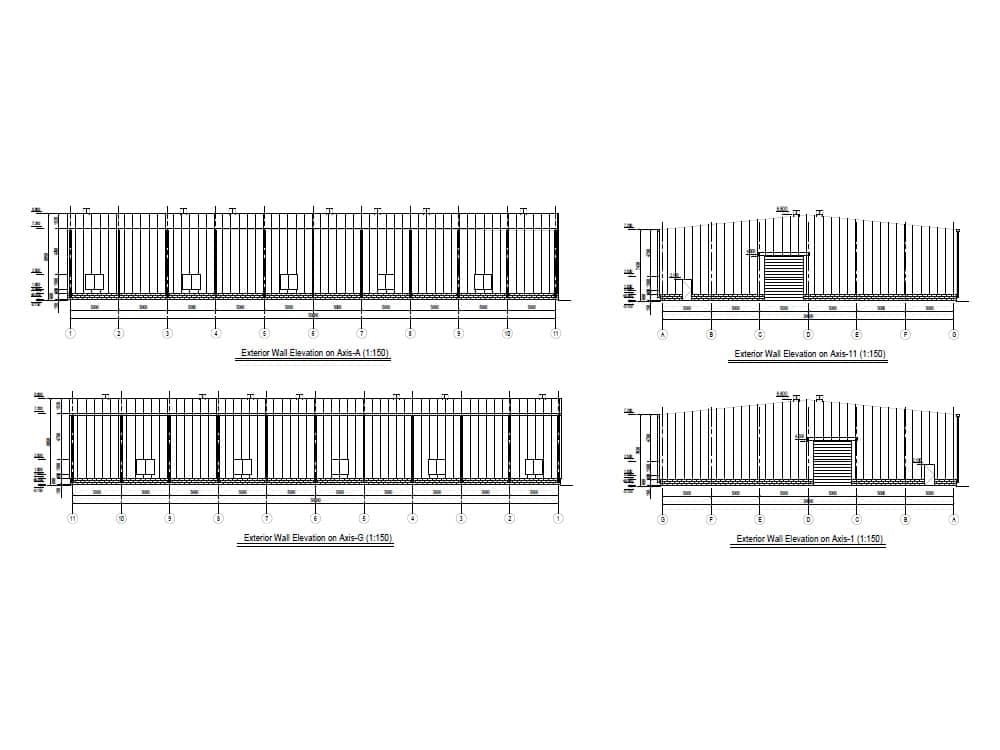

Portal Steel Structure Building Design Example | Case Study

In June 2024, we received an inquiry for a portal steel warehouse: 30x50x7m in size. The project site is close to the sea, the environment is humid and faces the threat of hurricanes, with a maximum wind speed of 250km/h. Such special project location and climatic factors place extremely high demands on the warehouse’s design, material selection, and structural safety. As the client had limited knowledge of prefab steel structure buildings, we needed a comprehensive and professional solution to ensure the warehouse can be used safely and stably in harsh environments.

Challenges of structural design

Wind Resistance

- With maximum wind speeds reaching 250km/h at the project site, our design team and structural engineers confirmed a column spacing of 5m to withstand hurricane impacts. This design enhances overall structural stiffness and stability, minimizing hurricane damage to the warehouse.

- High-strength steel materials are used, Q355B H-section steel for main steel components, and Q235B for secondary steel and purlins, improving wind load-bearing capacity. Connection nodes of the steel structure are specially designed and reinforced to ensure strength and reliability, preventing failure under hurricane forces.

- Effective wind bracing systems (horizontal and vertical braces) are installed on the roof and walls, forming a complete wind-resistant system to enhance overall wind performance.

Moisture Protection

- Given the humid environment, steel components undergo special anti-corrosion and moisture-proof treatment: multi-layer coatings (primer, intermediate coat, topcoat) are applied, with fluorocarbon coatings selected for their excellent moisture resistance, preventing water penetration into components.

- Strengthen the warehouse ventilation system to ensure air circulation and reduce the accumulation of humid air.

Final Material Selection for This Steel Structure Warehouse

1、Steel Components:

Main steel: Q355B high-strength H-section steel with fluorocarbon coating, offering excellent weather resistance, corrosion resistance, and chemical resistance to isolate steel from humid air and enhance waterproofing.

Secondary steel: Q235B galvanized or painted steel (galvanized layers prevent rust).

Purlins: Q235B galvanized steel to boost overall corrosion resistance.

2、Roof and Walls:

Standard color corrugated steel plates are upgraded to fluorocarbon-coated steel plate for enhanced moisture and corrosion resistance.

Brick walls are designed at the base to prevent rainwater backflow and provide collision protection, addressing frequent coastal rainfall.

3、Ventilation System:

In addition to wall windows, roof-mounted wind turbos improve air circulation and reduce moisture buildup.

4、Daylighting:

A combination of windows and skylight panels maximizes natural light, cutting electricity costs and energy consumption.

5、Main Gates:

Two 4×4.5m industrial electric rolling shutter doors are installed on both gable walls for smooth loading/unloading of large transport vehicles.

The benefits of using this design

1、High Safety: Fully accounting for hurricanes and humid conditions along the Philippine coastline, the design ensures warehouse safety and stability in harsh environments through rational structural planning, strict material selection, and reinforced connection points.

2、Strong Professionalism: Designed by our professional structural engineers, the solution complies with relevant national standards and codes, guaranteeing high professionalism and reliability.

3、Cost-Effective: While ensuring quality and safety, costs are reasonably controlled to provide clients with a cost-effective solution and quotation.

4、Easy Construction: Using portal steel structure frame, components are pre-manufactured in the factory for convenient on-site installation, shortening the construction period and improving efficiency.

K-HOME steel structure supplier – Reliable, professional manufacturer

Founded in 2005, Henan K-Home Steel Structure Co., Ltd. is a leading steel structure manufacturer dedicated to providing cutting-edge, high-quality construction solutions. With a comprehensive service covering design, manufacturing, processing, and installation, we offer end-to-end support for commercial, industrial, and infrastructure projects.

Combining over 20 years of industry expertise with a client-centric approach, we serve customers nationwide under our commitment to excellence. Our steel structures are renowned for durability and cost-efficiency, ideal for warehouses and industrial plants. With strong technical capabilities and timely execution, K-Home turns your vision into reality.

Frequently Asked Questions

SEND A MESSAGE