prefabricated Poultry Farm – steel structure farm

poultry farm shed / Prefabricated Poultry Shed / Prefabricated Poultry house / steel structure poultry farm / Poultry House Manufacturer

In modern poultry farming, efficiency, durability, and biosecurity are important; prefabricated poultry farms meet all these requirements. These prefabricated poultry sheds offer a robust, cost-effective alternative to traditional construction.

Steel poultry farms are weather-resistant, pest-proof, and corrosion-resistant. Poultry farm design ensures excellent airflow and smart space use, helping your chickens stay healthy and grow better while keeping maintenance costs low. Whether you’re a small-scale farmer or a large commercial operation, choosing the right poultry house can significantly boost profits.

What Are Prefabricated Steel Poultry Farms?

Prefabricated steel poultry farms are modern, pre-engineered structures designed for efficient and hygienic poultry housing. Unlike traditional brick farms, these prefabricated poultry sheds are made from high-quality steel frames, offering superior strength, durability, and quick assembly. A steel structure poultry farm provides a controlled environment with proper ventilation, insulation, and biosecurity features, ensuring optimal conditions for broilers, layers, or breeders.

These prefabricated poultry houses are customizable in size and layout, allowing farmers to scale operations as needed. Key advantages include resistance to fire, pests, and harsh weather, along with low maintenance costs. As a leading steel structure poultry house manufacturer in China, K-HOME ensures that each poultry house meets industry standards for safety, efficiency, and long-term performance. Whether for small-scale or industrial poultry farming, prefabricated steel structures provide cost-effective and sustainable solutions.

Why choose steel structure to build Prefabricated Poultry Shed?

As a result of their many advantages over conventional structure techniques, steel structures are progressively being utilized while constructing chicken farms. Steel structures are the most ideal choice for contemporary poultry farming in view of its many benefits, which include strength, flexibility, and speed of construction.

1. Durability and Longevity

The endurance of steel structures is one of the primary benefits of using them for chicken farms. Steel is famous for its versatility to serious climate, like intense heat, heavy rain, and strong winds. Along these lines, steel-outlined chicken farm structures are ideal for long-term use in different climates.

Since steel constructions are made to withstand corrosion and rust, they will endure longer and require less upkeep. Steel gives poultry farms the strength and steadiness they need to deal with natural stressors and support the heaviness of poultry equipment. Because steel is recyclable, its environmental impact can be minimized by repurposing it after its useful life.

2. Speed and Efficiency of Construction

Since steel structure buildings rush to raise, construction time can be significantly shortened. For poultry farms, where operations can’t manage the cost of extended downtime, this is important. Since our steel farm structures are pre-engineered, they can be gathered rapidly and make minimal measure of unsettling influence your company.

3. Flexibility and Customization

Depending on variables including the kind of chicken being farmed, the size of the business, and the surrounding environment, every poultry farm has different requirements. Steel buildings offer unparalleled adaptability, enabling farms to create unique solutions that meet their unique needs.

Steel structures can be laid out to suit needs, whether it is a small business to a large multi-building farm, steel structures can accommodate a variety of sizes. Our steel buildings can be easily expanded or modified to increase capacity without the need for a complete rebuild as your poultry business expands. In addition, steel buildings can be combined with cutting-edge agricultural technology to maximize farm efficiency, whether you need automatic feeding equipment, ventilation systems, or specialized lighting.

4. Cost-Effectiveness

One more huge benefit of steel constructions is their cost, especially when compared with more traditional structure materials. Steel might be more expensive initially, however, for poultry farm proprietors, the long-term reserve funds in upkeep, energy efficiency, and operating expenses might make it a more cost-effective choice.

Steel will require less maintenance over time because it is fire-, moisture-, and pest-resistant. Plus, a properly insulated steel structure can save energy by keeping chickens at an ideal temperature and reducing heating and cooling bills.

Three types of poultry farm construction:

Open side. It can save the cost of shed, but can not control the temperature very well, Open chicken houses are suitable for warm climate areas, and the building should consider sunshade and rain protection.

Half open side: you can open the curtain, when climate is good. You can close the curtain, when climate is not good. But this tpye chicken farm building can not be used in cold area, basically use natural ventilation, and can also be supplemented by mechanical ventilation. The window area must ensure both ventilation and heat radiation.

Enclosed poultry farm construction: This design can control temperature well and reduce the harm of climate changing to chickens. But the cost is higher. Enclosed poultry house must have good thermal insulation performance, and the temperature, air, and light in the house must be manually controlled to create a suitable growth environment for the chickens and maximize their production efficiency. In industrially developed countries, some chicken house structures use thin-walled steel and use high-efficiency thermal insulation roofs and walls, which are light in weight and quick to install.

Our poultry chicken farms are all prefabricated in factories. After standardized design and manufacturing in a controlled environment, they are transported to the site for rapid assembly. The main body of the poultry farm shed is constructed with high-quality steel, and the walls can be made of sandwich panels or solid steel plates. We provide fully customized services and can flexibly adjust the size, internal layout and functional configuration of the poultry farm according to the actual needs of customers, ensuring that each chicken house can perfectly adapt to your breeding needs.

Factors to consider when building a poultry farm shed

1、Site selection

The poultry farm shed should be away from residential and industrial areas and have good road connections. Consideration should be given to whether the selected site has basic facilities such as water and electricity. The poultry house should be built in a well-ventilated and high-lying place to prevent water accumulation.

2、Layout

Avoid external visitors from approaching the poultry farm shed. Good ventilation and appropriate space should be ensured. Egg storage, feed storage and offices should be close to the entrance to minimize the movement of people around the chicken house. Disposal pits and wards should be built only at the very end of the site.

3、Poultry Chicken house orientation (direction)

Areas south of 30°N: 15° east of due south (enhanced summer ventilation), areas north of 30°N: 10° west of due south (improved winter lighting)

4、Size of poultry house

The number of chickens raised and the availability of land determine the size of the chicken house. To ensure adequate ventilation, the chicken house width is about 20-25 feet. For environmentally controlled chicken houses, the width is about 40 feet because ventilation is controlled by exhaust fans. The height from the foundation to the roof is 6-7 feet, and the center height is 10-12 feet.

5、Floor of the poultry house

The floor of the poultry farm should be concrete and kept dry to prevent water from seeping into the poultry farm.

6、Roof

Our roof is made of high-quality steel. The roof can also be customized according to customer requirements.

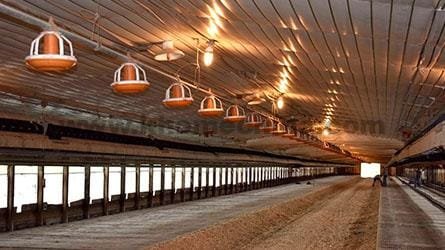

7、Lighting

The lighting is 7-8 feet from the ground and hung from the ceiling. The prefab poultry farm lighting uses incandescent lamps with a spacing of 10 feet or fluorescent lamps with a spacing of 15 feet. It is worth noting that different stages of breeding may use different light intensities and ensure different daily light hours.

Choice of chicken farming equipment:

1、Heating and insulation equipment:

Broilers have higher temperature requirements during the brooding or broiler stage, so broiler houses should have heating and insulation equipment. The heating and insulation equipment of broiler houses mainly includes electric heating umbrellas, coal stoves, infrared lamps or electric blankets, kangs and flue insulation.

2、Drinking equipment for broilers:

There are water troughs, tower vacuum drinkers, hanging tray automatic drinkers, nipple drinkers and cup drinkers.

3、Feeding equipment for broilers:

It is divided into two categories: ordinary feeding equipment and mechanical feeding equipment. There are long troughs, feed barrels, and open feeding trays.

4、Broiler house ventilation and cooling equipment:

Broiler chickens are raised at a high density, especially in the hot summer, and ventilation and heatstroke prevention and cooling should be strengthened. The commonly used ventilation and cooling equipment are: fans and fans, wet curtains-fan cooling equipment, automatic spray cooling equipment.

It is worth noting that at K-HOME we offer a variety of personalized steel structure poultry farm design solutions, but we do not provide equipment for poultry farming.

Choice of building materials of Poultry Farming:

The building materials required for poultry chicken houses can be roughly divided into five aspects, one is the poultry farm frame; the second is the roof/wall; the third is the floor; the fourth is the doors and windows.

1、 Frame of poultry farm shed

Modern poultry farm construction mainly adopts two types of industrial solutions: H-shaped steel structure and square tube structure. Scientific selection is required according to project budget, scale and environmental conditions.

H-shaped steel structure is an efficient industrial solution. They are mechanized in the factory, with high precision of finished products, fast on-site assembly and short construction period. The wind resistance level reaches 12 (wind pressure 0.6kN/㎡m²), the seismic fortification intensity is 8 degrees, and the service life exceeds 30 years.

The square tube structure is a low-cost poultry farm design solution. The main frame adopts hot-dip galvanized square tubes, matched with C-shaped steel purlins, and the material cost is lower than that of H-shaped steel. Suitable for mild climate zones.

2、roof/wall of prefab poultry farm shed

The poultry house roof/wall materials are usually color steel sheet or sandwich panel. The thickness of color steel sheet is 0.3mm-0.6mm, and the thickness of sandwich panel can be selected from 50mm-200mm and other materials. Chicken houses built with color steel sheet and sandwich panel have the characteristics of beautiful appearance, convenient and safe, and reusable.

3、floor of prefab Poultry House

The chicken house has no strict requirements on the ground, as long as it is flat, weed-free and disease-free.

4、doors and windows of prefab Poultry House

The chicken house has a tightly closed door, and a skylight or side window. A vent is built every 3-5 meters on the roof for ventilation in the house.

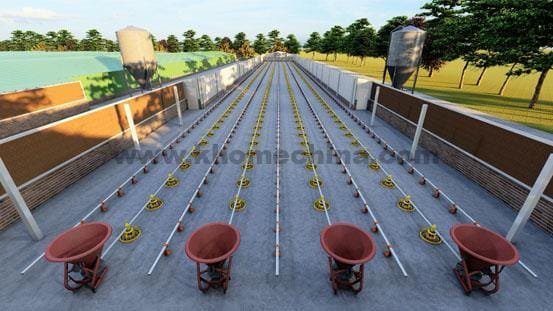

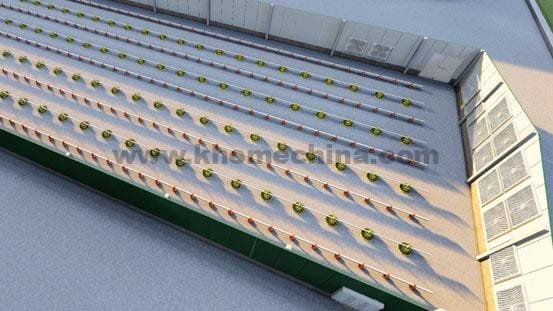

Case Studies – prefab poultry farm design plan

low cost Poultry Farm – Benin Poultry Farm Construction Solution

We planned and built a modern comprehensive chicken poultry farm for Benin customers. The project includes: 6 broiler breeding houses、2 laying hen breeding houses、2 breeder breeding houses、2 chick breeding houses.

All buildings adopt a combined construction method using masonry-concrete foundations (60cm high damp-proof walls) with steel structures. Considering the special needs of different breeding species, each building’s dimensions and functional design have been custom optimized.

During the initial project phase, we designed a steel structure solution using H-shaped steel for the client based on optimal performance considerations. This solution offered advantages of high industrialization level and rapid construction. However, detailed cost analysis revealed it exceeded the client’s budget.

Through professional evaluation, we optimized the structural solution to square tube steel construction while fully complying with all local load requirements (including wind and snow loads). This adjustment achieved significant cost reduction, meets the functional requirements of various poultry houses. Cost control saves about 30% of the original plan, maintains the fast construction characteristics of steel structure in construction, and can be customized for the special needs of different poultry.

The below is a rendering of a high-cost poultry house built with square tube steel structure. The optimized construction plan is fully presented for reference.

Prefabricated steel structure Poultry Sheds Manufacturer

Being one of China’s top suppliers of steel structures, we are in a unique position to satisfy the needs of poultry farm owners across the world. Our proficiency in the design and construction of superior steel farm buildings guarantees that you will obtain a long-lasting, reasonably priced, and adaptable solution for your poultry farm requirements.

1. Expertise and Experience

Having worked in the steel construction sector for many years, we have a thorough awareness of the unique needs of the poultry farming industry. Our engineering team ensures that every poultry farm is optimized for productivity and efficiency by closely collaborating with clients to develop buildings that precisely match their demands.

2. High-Quality Steel Materials

Our poultry farm structures are constructed using only the best steel materials. Our steel frames are robust, resistant to corrosion, and designed to endure the challenging circumstances that poultry farms frequently encounter. Furthermore, all materials are obtained from reliable vendors, guaranteeing the longevity and durability of your investment.

3. Efficient and Timely Solutions

At K-HOME, we make poultry house construction fast and simple. Our team uses computer-aided design technologies and smart design tools to create custom steel structures in minutes (not weeks). You’ll even see a 3D preview of your finished farm before we start building. Whether you need a small chicken house or a large commercial operation, we’ve got the right steel building solution for your needs.

4. Competitive Pricing

Being a Chinese direct manufacturer, we provide affordable prices without sacrificing quality. We can pass on large cost savings to our international clients by eliminating the middleman, which will make it simpler for poultry farm owners anywhere to obtain premium steel structure buildings at reasonable costs.

5. Global Shipping and Support

No matter where you are, we can deliver your steel poultry farm buildings with our effective worldwide shipping services. Our staff makes certain that the materials are packaged safely and delivered on schedule. We also provide continuing technical assistance and advice to guarantee the installation and efficient running of your chicken farm.

Frequently Asked Questions

SEND A MESSAGE