steel shed

Steel Shed Kits / metal shed / insulated steel shed / Steel Shed Building / steel frame shed / steel metal sheds

Steel sheds have become the first choice for industrial, agricultural, and commercial fields due to their durability, economy and fast construction. Whether it is a large factory that needs a spacious warehouse or a temporary factory building for a small business, prefabricated steel sheds can provide customizable solutions.

Prefabricated steel structures are popular because of their modular design and factory-based production. For example, prefabricated steel workshops use standardized parts for quick assembly and easy expansion. Since all components are made off-site, construction time is drastically reduced, helping businesses meet urgent deadlines. In addition, compared with traditional concrete buildings, steel’s lightweight and high-strength nature reduce foundation costs, while providing excellent resistance to wind and earthquakes.

Pre-Engineered Steel shed Buildings

Advantages of Prefabricated Design

Prefabricated steel shed buildings use components (main frames, purlins, wall panels, etc.) that are CNC cut, robot-welded, and mass-produced in a controlled factory environment. This approach offers three key advantages:

- Construction accuracy: With tolerances within ±2 mm, components can be seamlessly spliced, eliminating 90% of on-site adjustments in traditional construction.

- Time efficiency: Parallel processes (foundational work during factory production) enable 10,000 square meter facility projects to be completed in as little as 4-8 weeks

- Cost savings: Reduce labor requirements (typically 40% fewer workers) and minimize material waste (scrap rate is only 5%, compared to 15% for traditional buildings).

Flexibility and Customization

Modern steel structure building systems offer excellent adaptability through:

- Structural configuration: Clear spans up to 40 meters, no intermediate columns required, and eaves heights adjustable from 6 meters to 20 meters.

- Climate control: Optional insulated sandwich panels or natural ventilation.

- Systems Access solutions: Sliding doors or electric rolling doors for high trucks

- Special features: Mezzanine (load capacity up to 5t/m²) or lifting system (load capacity up to 50t)

Sustainability and Environmental-friendly

Steel shed buildings represent the forefront of green construction:

- Material circularity: ISO-certified recycled steel content (typically 30-90%), up to 98% recyclable at end-of-life

- Building ecology: 80% less construction waste through precision prefabrication. 60% less water use compared to concrete buildings

- Energy innovation: In areas where electricity is scarce, rooftops can be equipped with photovoltaic panels to generate electricity from the sun.

Affordable Metal Storage Sheds for every need

Metal storage sheds offer a budget-friendly alternative at just one-third the cost of traditional warehouses. This makes them perfect for users with limited budgets in various industries. Farmers use it to store large agricultural equipment such as tractors and harvesters, to avoid aging and damage caused by long-term exposure to the sun and rain. Small businesses use metal sheds to store parts needed for production and ensure a stable supply chain. Event organizers also love them – they can be quickly set up as temporary exhibition spaces, then taken down and reused, saving significantly on venue costs.

The secret to their durability lies in the galvanized steel construction. The zinc coating creates a protective barrier that fights rust, moisture, and even pest damage. With proper care, these sheds can last 30 years or more, eliminating the need for expensive replacements or major repairs.

Steel storage sheds are easy to install and maintain. These steel sheds adopt a modular design, and all parts have been prefabricated in the factory. Users receive precisely matched standardized components. Even beginners can assemble the basic model in 1-2 days using just common tools and the included instructions. This “ready-to-assemble” feature avoids the high labor costs of hiring a professional construction team and shortens the project cycle, saving time and money.

Maintenance is just as straightforward. Every few months, check that all bolts are tight and look for any coating damage. Loose bolts? Tighten them. Small scratches? A quick touch-up with anti-rust paint does the trick. These simple steps keep your shed in top shape for years with minimal effort.

Case: Successful Application

A Mexican client who runs a medium-sized farm looked for a steel structure warehouse for the growing demand for grain storage, and finally chose a metal storage shed. It was not only quickly built to catch the seasonal grains, but also achieved ventilation and moisture-proofing through reasonable internal space planning, effectively reducing grain mold loss. According to calculations, compared with the construction of traditional warehouses, the metal shed solution cut costs by 50%, while extending the shelf life of grains, indirectly increasing profits.

In the Philippines, a startup machinery company was unable to build a large warehouse to store production raw materials and finished products due to tight initial funds. After adopting a metal storage shed, they greatly reduced the storage cost. Also, the flexible design allowed them to start small and add more sections as their business grew. This low-cost and highly flexible storage solution helps enterprises effectively control costs in the initial stage, smoothly pass the stage of capital shortage, and lay a solid foundation for subsequent development.

Both cases show how metal sheds deliver more than just savings – they provide adaptable solutions that grow with your needs. Whether you’re storing crops or building a business, these affordable structures offer smart protection for your investments.

prefabricated insulated steel shed for SMEs

In the dynamic landscape of manufacturing, small and medium-sized enterprises (SMEs) are constantly looking for cost-effective, efficient, and adaptable solutions to enhance their production capabilities. Modular steel sheds have emerged as an attractive option, offering many benefits that cater specifically to the needs of SMEs.

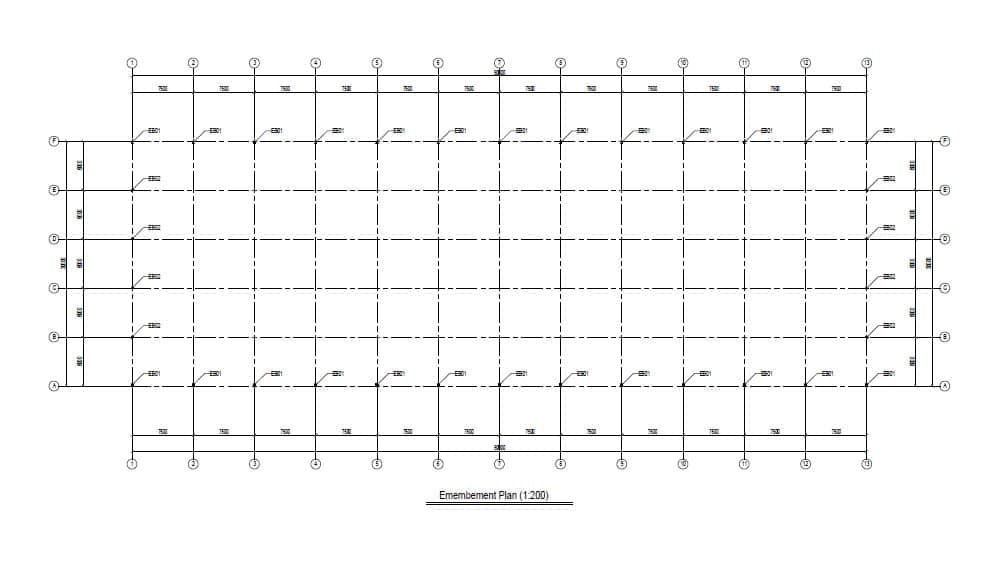

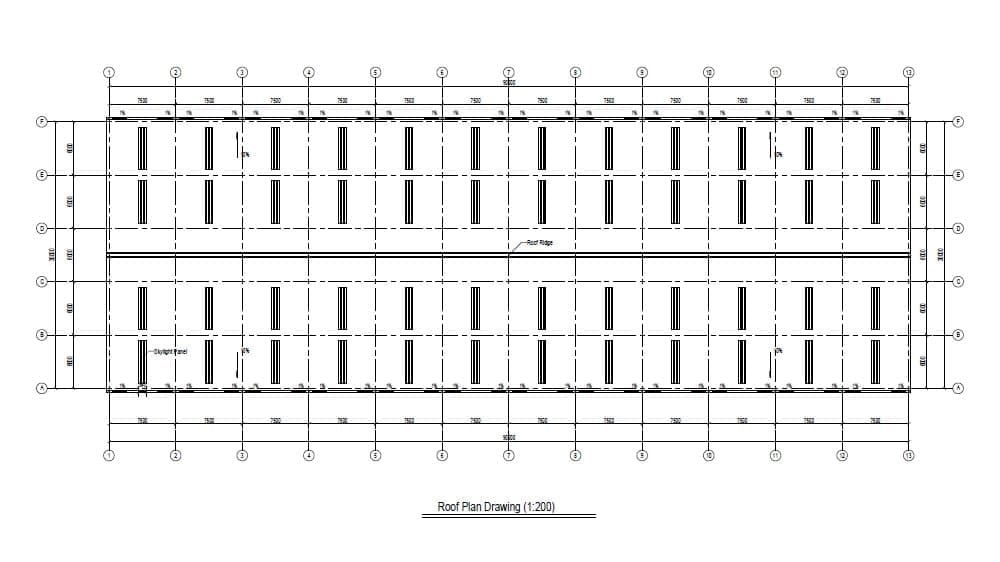

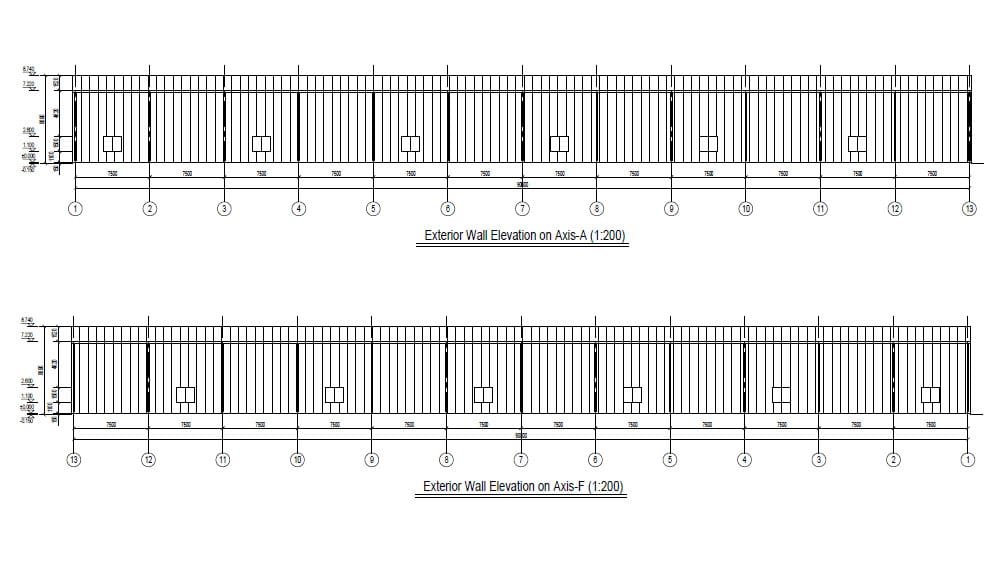

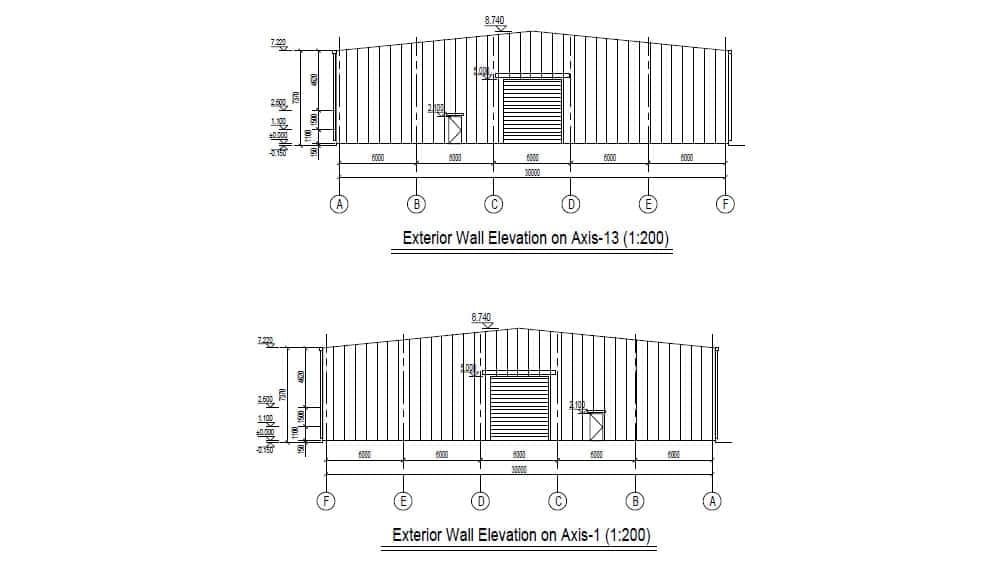

To further illustrate the benefits of prefab steel shed buildings for SMEs, let’s consider a case study of a 30 x 90 x 7 m portal single-span structure building. This type of structure is commonly used in manufacturing facilities due to its simplicity, cost-effectiveness, and flexibility.

Pre-Planning

The pre-planning phase for the modular steel shed was crucial to ensure that the final product met the specific needs of the SME. The manufacturer worked closely with the client to understand their production processes, equipment requirements, and future expansion plans. Based on this information, a detailed design was developed that optimized the use of space, ensuring efficient workflow and easy access to all areas of the workshop.

During the pre-planning phase, factors such as site location, soil conditions, and local building codes were also taken into account. The manufacturer conducted a thorough site analysis to determine the most suitable foundation type and ensure compliance with all regulatory requirements. This attention to detail in the pre-planning phase helped to avoid any potential issues during the construction process and ensured a seamless installation.

Design

The design of the 30x90x7 m steel workshop was tailored to the client’s specific needs. The open-plan layout provided a spacious and flexible workspace that could accommodate a variety of manufacturing operations. The high ceiling height of 7m allowed for the installation of overhead cranes, which were essential for moving heavy materials and equipment within the workshop.

The modular steel frame of the building was designed to be strong and durable, capable of withstanding the loads imposed by the manufacturing processes and the local climate. The use of prefabricated components ensured precise fit and easy assembly, reducing construction time and costs.

In addition to the structural design, the workshop was also equipped with a comprehensive ventilation and lighting system. The ventilation system was designed to maintain a comfortable working environment by removing heat, dust, and fumes generated during the manufacturing process. The lighting system consisted of energy-efficient LED fixtures, providing bright and uniform illumination throughout the workshop while reducing energy consumption.

Transportation

The transportation of the modular steel components from the factory to the construction site was a seamless process. The components were carefully packaged and then shipped by sea, ensuring their safe arrival at the destination.

Upon arrival at the site, the components were unloaded and staged for assembly. The modular nature of the components allowed for easy identification and organization, further streamlining the installation process.

Installation

The installation of the 30x90x7m structure building was completed in a relatively short period, thanks to the prefabricated nature of the components. The installation team followed a detailed installation plan, ensuring that each component was correctly positioned and secured. The use of specialized tools and equipment, such as cranes and welding machines, helped to speed up the installation process and ensure a high-quality finish.

During the installation process, quality control measures were implemented to ensure that the building met all safety and performance standards. The installation team conducted regular inspections to check for any signs of damage or misalignment and made any necessary adjustments. Once the installation was complete, a final inspection was carried out to verify that the building was ready for use.

Post-Installation

After the installation of the modular steel workshop was complete, the client was able to start their manufacturing operations immediately. The workshop provided a comfortable and efficient working environment that met all their production needs.

In addition, the flexibility of the modular design allowed the client to make future modifications and expansions to the workshop as their business grew. The ability to easily adapt the workshop to changing requirements provided the client with peace of mind and the confidence to invest in their business’s future.

The case study of the 30x90x7m portal single-span structure building demonstrates how modular steel workshops can be tailored to meet the specific needs of SMEs, providing a high-quality and functional workspace that can adapt to changing business requirements.

China Prefabricated steel shed building manufacturer

From the large-scale industrial application of pre-engineered steel industrial buildings, to the inclusive value of affordable metal storage sheds, to the ultimate pursuit of efficiency in modular steel workshops for manufacturing, steel structure sheds are reshaping the global construction industry. Their cost-effectiveness, flexibility, durability, and quick installation make them a practical and efficient solution for businesses looking to establish or expand their facilities.

For enterprises, investing in steel structures is not only a short-term cost-effective choice, but also a strategic layout for future competitiveness.

K-HOME focuses on providing customers with safe, reliable and cost-effective steel structure building solutions, and meets diversified needs through one-stop services throughout the entire process. We use advanced computer-aided design technology to quickly generate professional solutions that meet industrial standards; our senior design team simultaneously provides visual 3D renderings to achieve accurate presentation of design concepts and construction details.

From plan planning to construction implementation, we always adhere to the service concept of “quality first, value-oriented” to ensure that each steel structure shed achieves the best balance in terms of safety, durability and economy.

SEND A MESSAGE