Prefabricated Steel Building Tanzania

k-hOME – Steel structure experts from China: reliable, customized, cost-effective

Coping with Tanzania’s changing climate: KHOME’s durable prefabricated steel building solutions

Prefabricated steel buildings in Tanzania have become an increasingly popular choice for industrial, commercial, and agricultural projects. With Tanzania’s diverse climate—ranging from hot and humid coastal regions with temperatures averaging 28–32°C, to cooler highlands with significant rainfall—it is crucial to choose a construction method that is durable, adaptable, and cost-effective. A prefabricated steel building in Tanzania provides exactly that.

As a professional manufacturer in China, K-HOME specializes in delivering high-quality steel structure buildings designed to withstand Tanzania’s local conditions, comply with regulations, and offer long-term reliability.

Why Prefabricated Steel Building in Tanzania is Ideal for Local Climate?

Tanzania’s climate presents several construction challenges:

In Tanzania, the climate poses several construction challenges: in coastal cities like Dar es Salaam, high humidity and heat can accelerate corrosion in poorly treated structures; in the northern and western regions, heavy rainfall seasons demand strong roofing and efficient drainage systems; while in certain areas, occasional seismic activity and strong winds make structural stability a critical requirement.

To address these conditions, a prefabricated steel building in Tanzania from K-Home uses galvanized steel frames with anti-rust coatings, roof insulation materials, and flexible design that considers wind load, rain load, and thermal expansion. This ensures the building remains functional and safe over decades, even under harsh tropical weather.

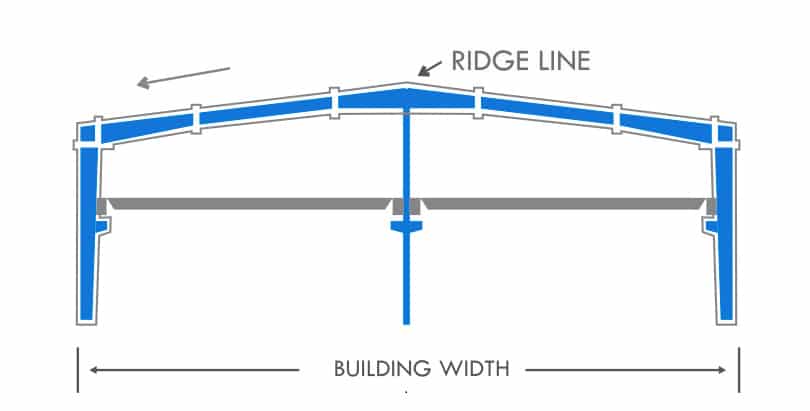

frame type of Prefabricated Steel Building

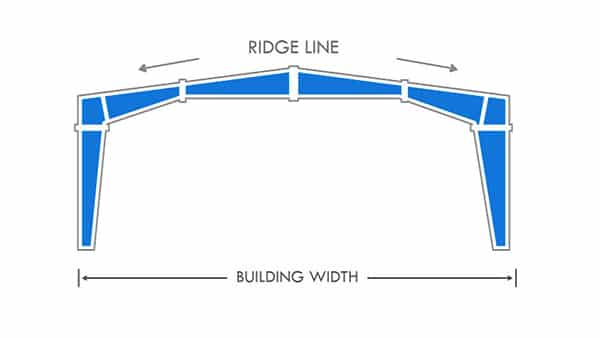

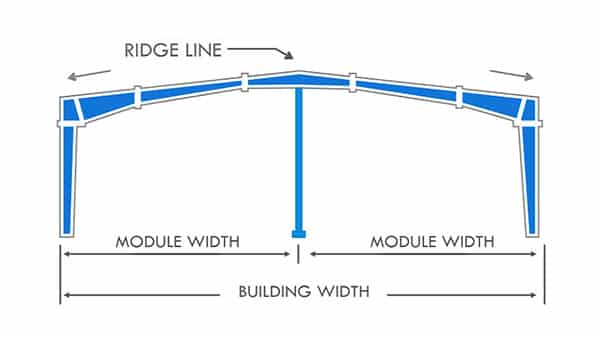

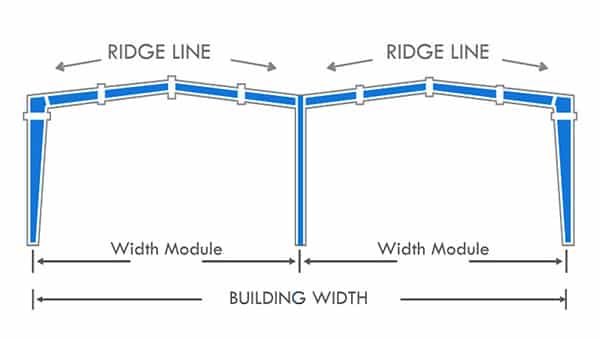

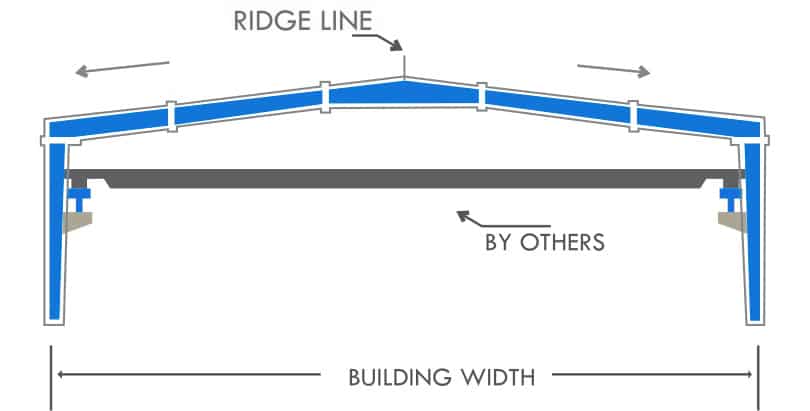

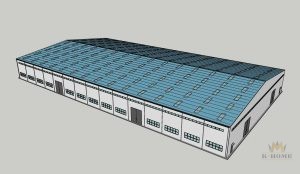

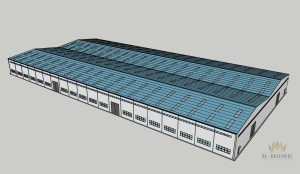

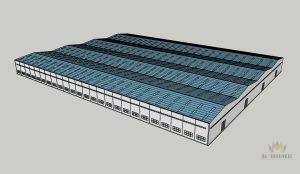

The structure has become a mainstream choice due to its superior performance. As a professional steel structure solutions provider, K-HOME’s high-performance steel portal frame system (clear span structure) meets the needs of various buildings. This structure is designed for single-story buildings requiring large open spans, and is particularly suitable for applications such as warehousing, logistics, and industrial plants.

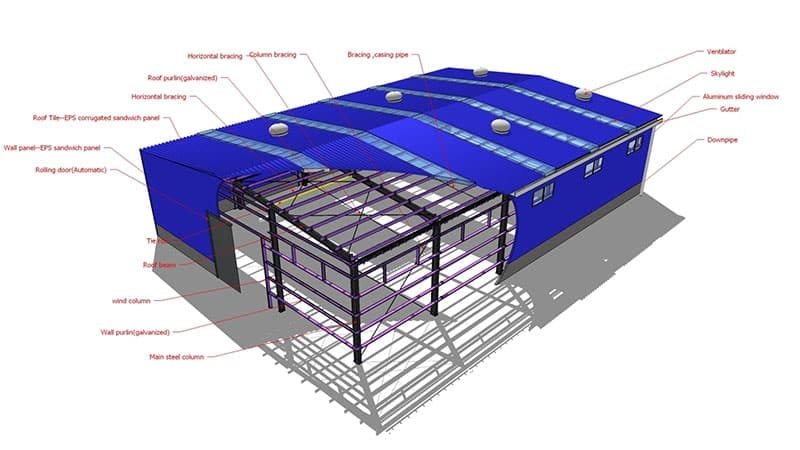

Key Components of Prefabricated Steel Building

The main frame of a prefabricated steel structure is primarily composed of Primary Frames, Secondary Members, and the enclosure structure.

Primary frames are the “backbone” that supports the entire building, consisting of vertical steel columns and horizontal steel beams. It is the core of the structure and carries the primary weight. Q355B high-strength steel is commonly used, formed into H-shaped steel sections through high-frequency welding. This shape is both strong and material-efficient.

Secondary Member provides auxiliary support. It includes components such as purlins, tie rods, braces, corner braces, and supports. Its function is to firmly connect the primary steel sections, prevent deformation and shaking, and enhance overall stability. Q235B steel is commonly used, and its surface is galvanized or painted to prevent rust.

Purlins are divided into roof purlins and wall purlins. Their function is to secure the roof or wall panels and transmit external forces such as wind and rain to the main structure. Q355B or Q235B galvanized Z-shaped steel is commonly used, as the Z-shaped design offers better load-bearing properties.

The enclosure structure often utilizes color-coated steel tiles or composite sandwich panels. Color-coated steel tiles are lightweight and durable, making them suitable for factories and warehouses with high space requirements. Composite sandwich panels are filled with materials such as rock wool, providing both thermal insulation and fire resistance. Customers can choose based on the project’s purpose and operating environment.

The more popular sizes of portal steel building kits

clear span metal building kits >>

multi span metal building kits >>

Prefabricated Steel Building in Tanzania Manufacturer in China – Why Choose K-HOME?

As a leading manufacturer in China, K-Home provides end-to-end solutions for prefabricated steel building in Tanzania. Our services include:

K-HOME provides a comprehensive solution for prefabricated steel building in Tanzania, offering custom design with structural engineering that considers local wind speed, rainfall, and soil conditions, combined with advanced production using automated cutting, welding, and surface treatments to ensure precision and durability.

With optimized logistics, all parts are pre-labeled and documented for fast delivery and efficient assembly, while on-site support includes detailed installation manuals, 3D guides, and optional technical assistance. Moreover, the use of 100% recyclable steel and a prefabrication process that minimizes waste highlights K-Home’s commitment to sustainability and environmental responsibility.

By working with K-HOME, Tanzanian clients benefit from international-grade quality, shorter construction time (30–50% faster than concrete), and cost transparency.

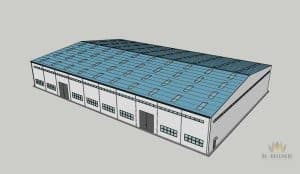

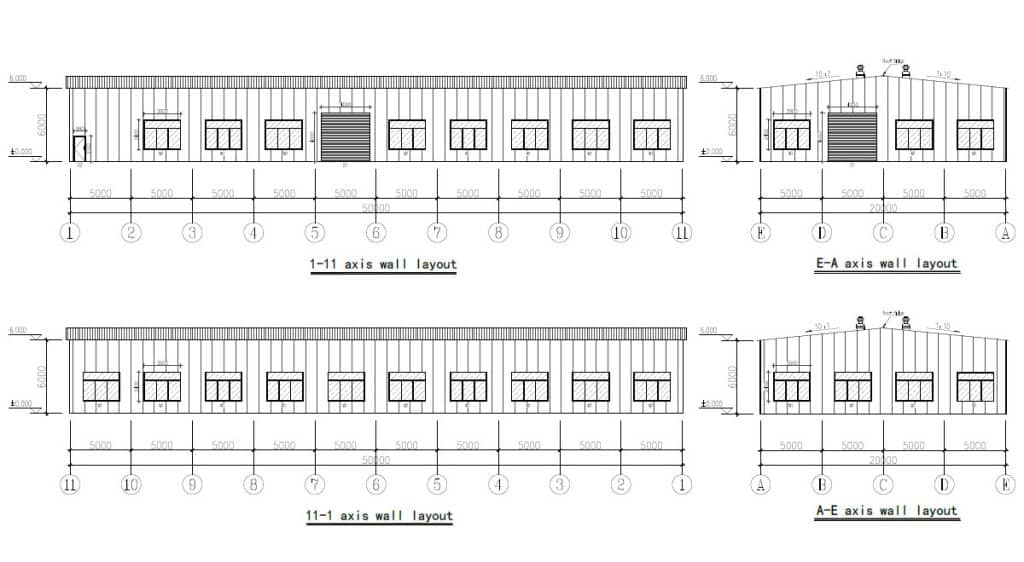

Case Study: 20m × 60m × 6m Prefabricated Steel Warehouse in Tanzania

One of our recent projects involved delivering a prefabricated steel warehouse in Tanzania, measuring 20m × 60m × 6m. The client required a structure for storing agricultural products, with insulation against heat and rain.

In this project, the walls and roof were installed with color steel sandwich panels that provide effective insulation, reducing internal heat by up to 10°C, while the structural design featured an optimized steel frame capable of withstanding heavy rainfall and seasonal winds. Thanks to the prefabricated system, the entire assembly was completed within just a few weeks, minimizing downtime and ensuring the client’s operations could continue smoothly.

The client was satisfied not only with the durability but also with the cost-efficiency compared to traditional concrete structures. This example demonstrates how prefabricated steel building in Tanzania can be customized to meet specific industrial needs.

Industrial Applications of Prefabricated Steel Buildings in Tanzania

A prefabricated steel building in Tanzania is not limited to warehouses; it is widely used in different industries:

Warehousing and Logistics

Warehouses must store diverse goods, from grains to machinery. For grains, insulated wall panels help control temperature and moisture. For machinery, non-insulated but well-ventilated designs are more cost-effective. Each variation affects both material selection and overall cost.

Manufacturing Plants

Many factories require integrated crane systems for heavy equipment handling. When a crane is added, the steel consumption of the building increases, which directly impacts the price. K-Home designs each prefabricated steel building in Tanzania according to the lifting capacity and span of cranes required.

Agricultural Buildings

From poultry farms to crop storage, agricultural facilities in Tanzania face challenges from heat and humidity. Steel buildings provide hygienic, easily maintained environments, with optional climate-control features for sensitive products.

Commercial and Office Spaces

Prefabricated steel structures are also adapted for commercial use, offering open-plan layouts, quick construction, and lower long-term maintenance.

By understanding the function of the building, clients can work with K-Home to choose the most cost-effective design.

Prefabricated Steel Building in Tanzania Price

When investing in a prefabricated steel building in Tanzania, price is often a major concern. The cost is not fixed but depends on multiple factors:

The cost of a prefabricated steel building in Tanzania is influenced by several factors, including size and dimensions, as larger spans and taller heights require more steel, as well as material specifications, since thicker steel, insulation panels, and corrosion-resistant coatings will increase expenses.

Functionality also plays a role, as warehouses equipped with cranes or specialized machinery demand reinforced designs, while climate adaptation measures such as additional insulation, waterproofing, or ventilation systems can further impact pricing. Additionally, transportation and installation costs vary depending on the distance from port to site, accessibility, and the availability of local labor in Tanzania.

On average, a prefabricated steel building in Tanzania can be 20–30% more cost-effective than traditional concrete structures, especially when long-term maintenance and operational savings are considered.

How to Confirm Your Prefabricated Steel Building Project in Tanzania with KHOME?

Choosing the right design is the first step to a successful project. At KHOME, we offer:

KHOME provides a one-stop, worry-free experience for prefabricated steel building projects. We offer free consultation and design services, and our engineers will carefully customize a layout based on your site conditions and intended use.

We ensure transparent quotes, accurately calculating the required steel quantity, insulation requirements, and accessory costs to provide you with a clear and detailed cost breakdown. With our one-stop service, we manage the entire process from design, production, transportation, and installation. We also provide professional after-sales support, ensuring ongoing technical support during maintenance and future renovations.

This seamless service system ensures that every prefabricated steel building in Tanzania meets customer expectations and complies with local standards.

A prefabricated steel building in Tanzania offers unmatched durability, speed, and cost-efficiency, making it the best choice for warehouses, factories, agricultural facilities, and commercial spaces. With Tanzania’s challenging climate, steel structures from K-Home, a trusted manufacturer in China, deliver long-term solutions adapted to local needs.

Whether you need a small warehouse or a large industrial plant, working with K-Home guarantees not only quality but also a stress-free building experience. Contact us today to start your prefabricated steel building in Tanzania project and benefit from our one-stop, professional service.

SEND A MESSAGE