modular clean booth

portable clean booth / clean room booth / clean work booth / Pharmacy Clean Room

Want to create a clean environment with high cleanliness while taking cost control? Modular cleanrooms will be your ideal economical choice.

In the pursuit of a high clean environment, modular clean booths have become the preferred choice of many companies and scientific research institutions due to their unique advantages. It can not only effectively control costs, but also be deployed quickly to meet the multiple needs of independence, efficiency, and cleanliness. Next, we will explore in depth the operating principles, design solutions, and many advantages of modular clean booths.

what is a clean booth?

A clean booth, also known as a clean work booth or dust-free cleanroom, is a small independent space designed to create a highly clean working environment. Its core feature is the use of high-efficiency Fan Filter Units (FFUs) to deliver clean air to the internal area, ensuring that the clean class of the working environment meets the specified standards.

Structurally, the clean booth adopts a modular design, facilitating a flexible factory or laboratory layout. In addition, its installation, disassembly, and movement are simple and fast, with a high degree of flexibility. They can quickly transfer and reconfigure between different locations to meet diverse application needs.

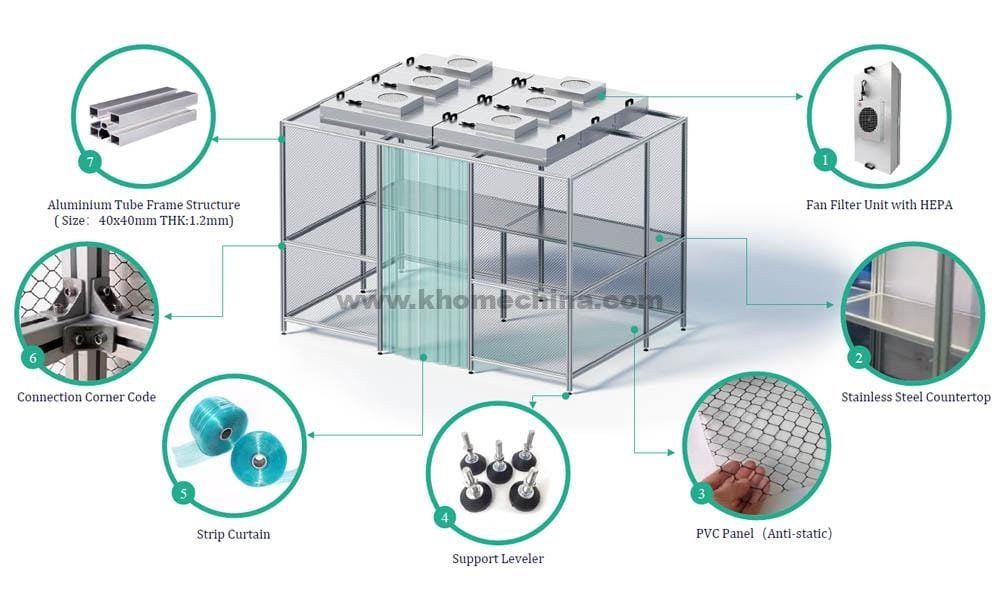

Portable Clean Booth Technical Specifications

The portable dust-free clean room is an economical, efficient, and high purification level simple purification equipment. It adopts industrial aluminum profiles to construct the frame, with PVC anti-static mesh curtains as the enclosure structure, ensuring the stability of the structure and internal electrostatic protection. At the top of the clean booth, there is a fan filtration unit (FFU) equipped with a high-efficiency particulate air filter (HEPA), which enables the indoor area to achieve cleanliness standards of 100 to 100000 levels.

As key equipment in various fields such as medicine and health, biological products, food processing, electronics, and hard disk manufacturing, dust-free clean rooms are widely used in sample sampling, cargo transfer, and local environmental purification operations, meeting the purification needs of different fields with their mobility and efficiency.

- Frame: 40*40mm Aluminium tube (THK:1.2mm)

- Enclosure structure:0.3mm PVC anti-static mesh curtain, high transparency, good flexibility, no deformation, not easy to age, dustproof and anti-static. You can also choose 5mm acrylic panels

- Door: The standard module is equipped with PVC door curtains, and we also provide hinge doors, plastic rolling shutter doors, swing doors, etc

- Adopting a dedicated purification lamp for the clean room does not produce dust

- Fan filter unit (FFU): using the centrifugal fan, it has the characteristics of long life, low noise, maintenance-free, low vibration, and stepless speed change. FFU is equipped with an efficient filter with a filtration efficiency of 99.99% 0.3UM

FFU: The core part of a clean room

As a closed structure that provides a highly clean environment, clean work booths are widely used in fields such as electronic manufacturing, biomedicine, and laboratories. However, achieving cleanliness and uniform airflow inside the clean booth cannot be achieved without the contribution of FFU.

First, FFU’s air supply and filtering are crucial for protecting a clean environment. With its built-in fan and filter, FFU can draw in outside air, filter it, and remove tiny particles, bacteria, viruses, and other pollutants. This cleaning process makes sure the air inside the clean booth is good quality, giving workers a reliable and clean place to work.

Second, the uniformity of FFU’s airflow is very important for the operation of the clean booth. The airflow generated by FFU can be evenly distributed inside the clean booth, covering the entire work area. This even airflow distribution ensures consistent cleanliness, preventing situations where there are local pollution or differences in cleanliness inside the clean booth.

Also, FFU has adjustable airflow and speed controls. You can change the airflow and wind speed as needed. This flexibility helps the clean booth meet different cleanliness requirements and situations. For example, when higher cleanliness is needed for some tasks, you can increase FFU’s airflow and wind speed to provide more clean air.

FFU and the clean booth are closely connected. As a key part of the clean booth, FFU protects the clean environment by cleaning the air, providing clean air, and keeping the airflow even. During the design and installation of the clean booth, the selection and layout of FFU require detailed planning and consideration,to make sure the clean booth can meet the expected cleanliness requirements.

In practical applications, the performance and maintenance of FFU also need attention. Regularly replacing filters, cleaning equipment, and performing timely maintenance can ensure the normal operation and lasting performance of FFU. At the same time, a reasonable layout and number of installed FFU can ensure that the entire clean booth is fully covered with clean air.

The Cleanliness class of Clean Booths

The class of clean booths refers to the degree of cleanliness of the air inside, typically classified as Class 100, Class 1000, and Class 10000.

A Class 100 clean booth corresponds to the cleanliness level of ISO 14644-1 Standard Class 1, representing the highest level. Its cleanliness requirements are extremely high, with no more than 1,000 particles larger than 0.1 micrometers in diameter per cubic meter of air inside. This type of clean booth is commonly used for manufacturing high-precision, high-purity products such as semiconductor chips and optical components. In a Class 100 clean booth, high-efficiency filters, air showers, and other equipment are required to ensure the highest level of air cleanliness. Additionally, staff need to wear special cleanroom suits to prevent the introduction of external contaminants.

A Class 1000 clean booth corresponds to the cleanliness level of ISO 14644-1 Standard Class 2. The number of particles larger than 0.1 micrometers in diameter does not exceed 10,000 particles per cubic meter of air inside. Class 1000 clean booths are typically used in the production of semiconductors, electronics, pharmaceuticals, and other industries.

A Class 10000 clean booth falls within the cleanliness levels of ISO 14644-1 Standards Classes 3 to 6. The number of particles larger than 0.1 micrometers in diameter does not exceed 100,000 particles per cubic meter of air inside. Class 10000 clean booths are commonly used in the production of food, cosmetics, and other industries. In this type of clean booth, primary, secondary, and high-efficiency filters are required. Regular cleanliness testing and maintenance are also necessary to ensure that the cleanliness standards are met.

Beyond differences in cleanliness levels, various types of clean booths also exhibit differences in design and construction. For instance, Class 100 clean booths require a fully enclosed structure to prevent external air from entering. In contrast, Class 1000 and Class 10000 clean booths can adopt a semi-enclosed structure to facilitate the movement of personnel and materials. Additionally, different types of clean booths need to consider internal environmental factors such as temperature, humidity, and pressure to ensure optimal production environments and product quality.

How to Determine the Number of FFUs in a Modular Cleanroom Booth?

In a modular clean work booth, an important piece of equipment is the FFU (Fan Filter Unit). It comes with its own power supply and can draw in outdoor air, purify it, and then blow it into the room. The number of FFUs is related to the purification capacity of the clean work booth. The number of FFUs needs to be determined through calculation, rather than being increased or decreased at will. Adding too many will increase costs, while reducing them will fail to meet the specified cleanliness level. So, how do we determine the number of FFUs needed for a dust-free clean room booth?

To determine the number of FFUs in a cleanroom, we only need to know three values: the air change rate, the volume of the cleanroom, and the air volume of the FFU. The specific calculation formula is: N = A * J / K (where A is the air change rate, J is the volume of the cleanroom, K is the air volume of the FFU, and N is the number of FFUs required).

air change rate

What determines the air change rate? To determine the specific air change rate, we need to choose the clean booth class and then identify the corresponding number of air changes per hour based on that class. A higher air change rate indicates that more airflow is required to maintain the air quality in the clean booth. Below is a commonly used reference standard:

| Class | Air Changes Rate per Hour | Commonly Selected Value |

| Class 100 | ≥200 | Generally 230 |

| Class 1000 | >50 to <100 | Generally 70 |

| Class 10000 | 25-30 | — |

| Class 100000 | 15-20 | — |

| Class 1000000 | 12-15 | — |

The volume of clean booth

Not only does the area of the cleanroom affect the number of FFUs (Fan Filter Units), but the height is also important. Both are fundamental for calculating the required air volume. According to the relevant specifications for prefabricated clean booths, the prescribed number of air changes applies to clean booths with a height of less than 4 meters. If the height is higher, additional measures such as increasing the number of air changes may be needed to achieve the desired cleanliness class.

the air volume of FFU

The air volume of an FFU (Fan Filter Unit) depends on its model and specifications. Here are some common FFU airflows and their characteristics:

Rated Air Volume Standards:

- 1000-type FFU: Its rated air volume is usually 1000 cubic meters per hour (m³/h). This type of FFU is suitable for air filtration in smaller spaces, such as clean benches and small clean rooms.

- 2000-type FFU: Its rated air volume is generally 2000 cubic meters per hour (m³/h). It is used for air filtration in medium-sized spaces, often found in cleanrooms, biosafety cabinets, and other places that require high air cleanliness.

- 3000-type and 5000-type FFU: These have air volumes of 3000 cubic meters per hour and 5000 cubic meters per hour, respectively. They are suitable for large cleanrooms, industrial purification plants, and other settings.

The air volume of an FFU directly affects its air filtration effectiveness and the cleanliness of the clean booth. Generally speaking, the larger the air volume, the better the filtration effect and the higher the cleanliness. In practical applications, selecting the appropriate air volume for an FFU requires comprehensive consideration of factors such as the specific needs of the clean work booth, the cleanliness level required, work requirements, and equipment layout.

At K-HOME, you don’t need to worry about such complicated design calculations. You can leave all these issues to us. We have professional designers who can perform calculations based on clean booth standards to ensure the accuracy and reliability of the clean booth’s operation. Our expert team will do our best to provide you with cost-effective solutions.

clean work booth design

The movable clean work booth is one of the important facilities in modern production processes, and its design specifications play a crucial role in ensuring product quality and the production environment. The factors that affect the clean booth design mainly include size, structure, and cleanliness class.

Size Requirements

A movable clean work booth size should be customized based on actual production needs and site conditions. Generally, a clean work booth with a countertop is 1.8 meters high. If it doesn’t have a countertop inside, it’s usually 2 meters or higher. The width and length should be designed according to the size and usage requirements of the production equipment.

Structural

The frame of the clean booth is made of aluminum alloy profiles to ensure structural stability and prevent rusting and deformation. Its outer structure usually uses materials that don’t produce or easily accumulate dust, and the surface should be smooth and flat, with no particles falling off. The clean booth is often designed as a movable modular structure for easy transportation and site adjustments.

Cleanliness class Requirements

The cleanliness class of the clean work booth should meet the needs of the working environment, typically designed to be at the hundred, thousand, or ten thousand class. To achieve the required cleanliness, reasonable layout planning, air supply, and exhaust systems, and filter selection should be considered during the design process. Additionally, the clean work booth should be regularly maintained and serviced during use to ensure normal operation and that the cleanliness class is met.

In the actual design process, the clean work booth should be comprehensively considered based on actual production needs and site conditions to ensure it meets production process requirements and has good safety, comfort, and environmental protection features.

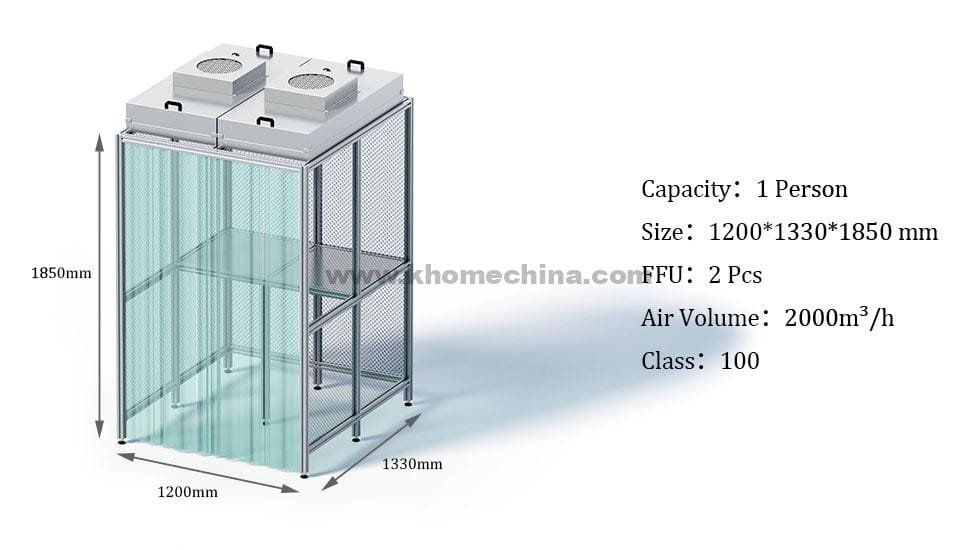

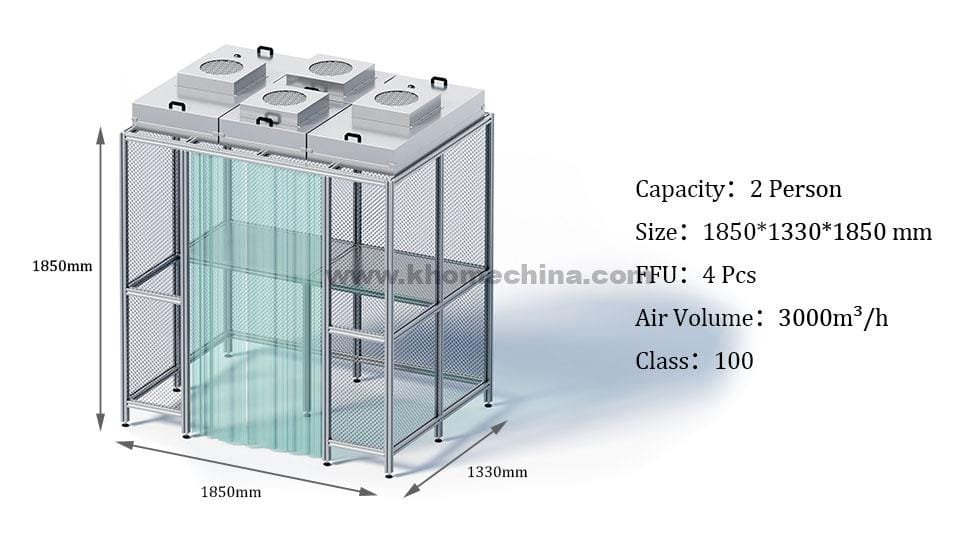

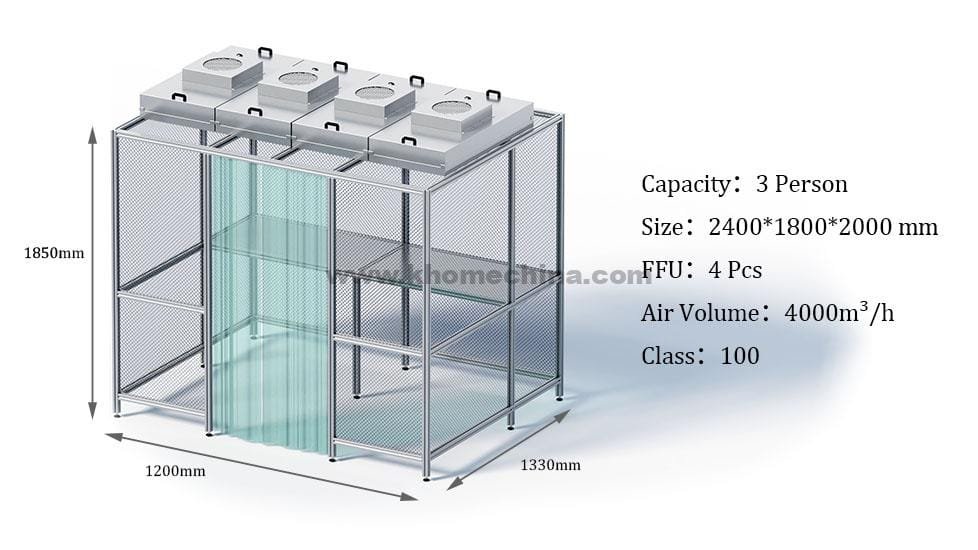

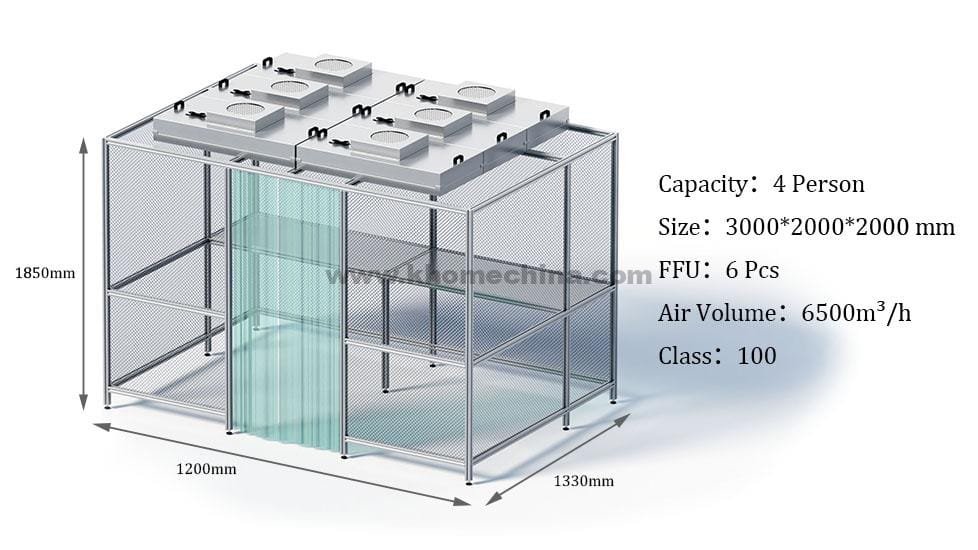

Below are some 100 class clean booth model references. If you want to know more, you can contact K-HOME directly to get more customized designs.

100 Class Clean Booth Capacity:1 person 100 Class Clean Booth Capacity:2 person 100 Class Clean Booth Capacity:3 person 100 Class Clean Booth Capacity:4-5 person

Where can clean work booths be used?

For industries with strict requirements on the cleanliness of the production environment, the demand for modular clean booths is particularly significant. This type of clean booth can be integrated into a traditional building or placed in a dedicated steel purification workshop. It is specially designed for local high-cleanliness production processes. Its modular structure and compact size give it extremely high flexibility and can be widely adapted to application scenarios in multiple industries to achieve precise and efficient purification needs.

1、Clean booths in the electronics industry: In the field of electronics manufacturing, the production of sensitive electronic components requires extremely high environmental cleanliness. Clean work booths provide an ideal solution for this demand. It can create a local clean environment, effectively isolate the production area from the outside environment, prevent the intrusion of dust and particulate matter, and thus protect electronic components from contamination. This temporary clean space is not only cost-effective, but can also be quickly built and adjusted according to production needs, providing great flexibility for the precision manufacturing of electronic components.

2、Pharmaceutical Clean Booth: Clean booths also play an important role in the field of pharmaceutical production. It can be used as a temporary clean room in drug production or biological experiments to ensure the accuracy of the experiment. The flexibility of clean booths makes it an ideal choice for small-scale production or experiments, especially when it is necessary to respond quickly to market changes or conduct special drug research and development. In addition, the portability of clean sheds also makes it highly valuable in emergency situations or temporary projects.

3、In the field of precision assembly, such as the assembly of optical instruments or high-precision mechanical parts, cleanliness is also crucial. The clean room booth ensures the cleanliness of the air during the assembly process through its built-in high-efficiency filtration system and the positive pressure environment it maintains, thereby ensuring the assembly quality. It provides operators with a stable and clean working environment, reducing assembly errors and product defects caused by environmental factors.

5、In the food production process, it is generally recommended to use a Class 100 clean room booth for the packaging process. The higher the level, the higher the safety compliance rate of the food produced. In recent years, the use of clean sheds in the food industry has become more and more widespread.

Features of clean room booth

- The clean booth adopts modular design, which is easy to assemble and has low installation cost.

- It can be moved freely to reduce the unnecessary expenses of clean room booth.

- It has compact design, light weight, and is equipped with casters. The four-sided transparent vinyl curtain with mobility.

- The clean booth class can be easily achieved between 100-10,000.

- Multiple units can be combined to achieve different cleanliness level requirements of large clean areas.

prefabricated clean booth supplier

Clean booths are custom structures that require a combination of multiple parameters to provide a suitable layout. This expertise may be challenging for you. But rest assured, K-HOME has the expertise to provide you with a clean booth that meets the standards. In addition, our team can support you throughout the process to ensure the smooth construction of your clean room booth or clean workshop.

SEND A MESSAGE