Portable Container Office For Offshore

The Portable Container Office uses all environmentally friendly materials, and all components are assembled and welded in the factory. The top and walls are all-welded. It can be assembled by multiple container houses to expand the space area. Beautiful appearance, not easy to rust with many rust spots, container mobile house (two windows, one door, distribution box, fluorescent lamp, socket, etc.), the frame belongs to the light steel structure, including the ground, roof, and four-corner frame, its outer wall It is made of steel plate, which has the unique physical properties of construction methods and materials, providing a comfortable environment for the interior.

The Portable site office is mainly used in infrastructure construction sites such as Construction Site Temporary Housing, subway construction sites, municipal engineering construction sites, railway construction sites, highway construction sites, water conservancy construction sites, and company temporary kitchens.

Portable Container Office Convenient and Practical

It is increasingly used on construction sites as an office.

The project site may be located far away or rugged. In addition to the workers’ dormitory, you also need to build a work area for the project principal, engineers, technicians, etc.

With traditional buildings:

1: The distance is far, the raw materials are not easy to transport.

2: The construction time is slow, which will delay the progress of the project.

3: After it is completed, the second decoration is needed, so it cannot be used immediately.

So if use the portable container office, you only need to find a relatively flat place to put it down and put three or five tables and chairs inside, which can be used directly.

Electricity and water power can be installed together with the house at the same time. Such a simple house can meet everything needed for normal office work.

Portable Container Features

- Convenient transportation, especially suitable for units that frequently change construction sites;

- Rugged and durable, the frame is made of steel, which has strong seismic and deformation resistance;

- Good sealing performance, strict manufacturing process makes this kind of mobile room have good water tightness;

- The mobile house is based on a standard steel chassis, which can derive a lot of combined space. Such as meeting rooms, dormitories, kitchens, bathrooms, etc. The standard width is 3 meters, the height is 2.8 meters, and the length is 6 meters.

- Convenient disassembly and assembly, superior performance, stable and firm, good shockproof performance, waterproof, fireproof and anticorrosive, and light weight. The house is an integral structure with a frame inside, and the walls are made of color steel composite panels, which can be moved as a whole, and the service life can reach more than 20 years.

Photo Gallery >>

Portable Container House VS Prefabricated House

Besides portable container houses, there is another kind of temporary building, called a prefabricated house.

They belong to temporary buildings, but there are many differences. You can choose which product to use according to the actual needs of your project.

1. Structure Comparison

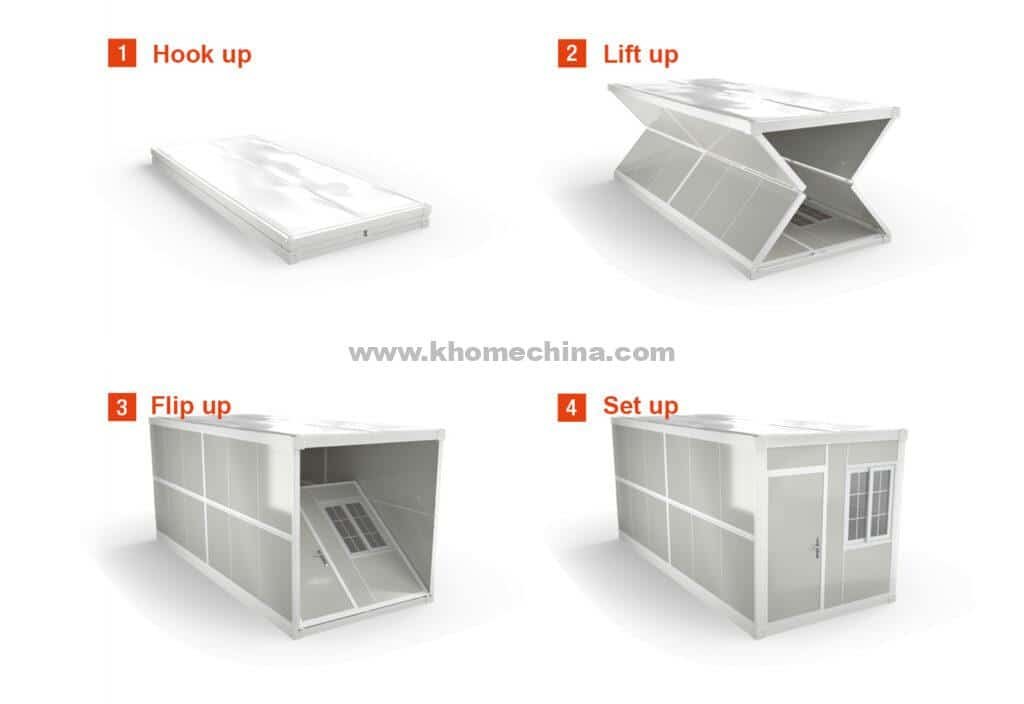

The portable container house is a modular structure. The steel structure adopts galvanizing technology. It consists of a structural system, floor system, wall system, and roof system. Each system is composed of several unit modules. The unit modules are manufactured in the factory. After completed, it is assembled on site.

The prefabricated house needs to be built with the foundation. The resistance is small, and it is easy to collapse when the foundation is not solid, typhoons, earthquakes, etc.

2. Design Comparison

The design of container houses introduces modern household elements, according to the different environments of the house, according to the needs, free assembly, and disassembly. According to the changes in the environment, the user can choose the assembling method of each module to create a personalized house. The adjustable house base can also be adapted to the requirements of different grounds. Other building decoration materials can also be attached to the exterior of the house as an enclosure structure and surface decoration or decoration.

The top frame of the container house adopts thermal insulation measures, and the design is more reasonable.

According to the standard, each room is a whole room or several rooms, or it can be a part of a large room. It can be assembled and combined in any length and width direction and can be stacked in three layers.

Modeling roofs, terraces, and other decorations can be added. Each room is decorated according to the standard and can be equipped with all living facilities.

The design of the prefabricated house is based on raw materials such as steel and plates for on-site installation, and the performance of sealing, sound insulation, fire prevention, moisture resistance, and heat insulation is poor.

3. Performance Comparison

The container house is earthquake-resistant to level 8, and wind-resistant to level 12, with a service life of more than 20 years.

The container house has high-quality materials, can be recycled, and is economical and environmentally friendly. The wall adopts fireproof sandwich panel, and the components are connected with no cold bridge.

When subjected to vibrations and impacts, cold bridges will not occur due to the shrinkage of the core material, which prevents bulk insulation materials from being shaken. A cold bridge appears on the upper part of the component. Rock wool strips can maintain good thermal insulation performance regardless of high temperature or low temperature. It has the characteristics of non-combustible, non-toxic, lightweight, low thermal conductivity, good sound absorption performance, good edge retention, good chemical stability, and long service life.

The prefabricated house has level 7 earthquake resistance and 9 wind resistance, 10 years of service life, 2-3 times of disassembly and assembly (this is based on better materials), and has poor fire resistance, moisture resistance, sound insulation, and heat preservation performance.

4. Transportation Comparison

The container house can be transported as a whole without disassembling.

The prefabricated house needs to be disassembled and transported. Disassembly and reassembly can easily damage the parts and reduce the life of the house.

5. Appearance Comparison

The modular container house can be simple and luxurious. It can be used in engineering camps, logistics parks, military, municipal administration, commerce, oilfield mining, tourism, exhibitions, etc. It can be used for living, office, storage, commercial operation, tourist landscapes, etc., which improves comfort and meets the needs of life.

The prefabricated is simple in appearance and is basically only used for temporary construction sites.

6. Steel Content Comparison

The container house contains a lot of steel, is stable and hard, and has a long life.

The prefabricated house contains less steel and has a short lifespan.

Related Products

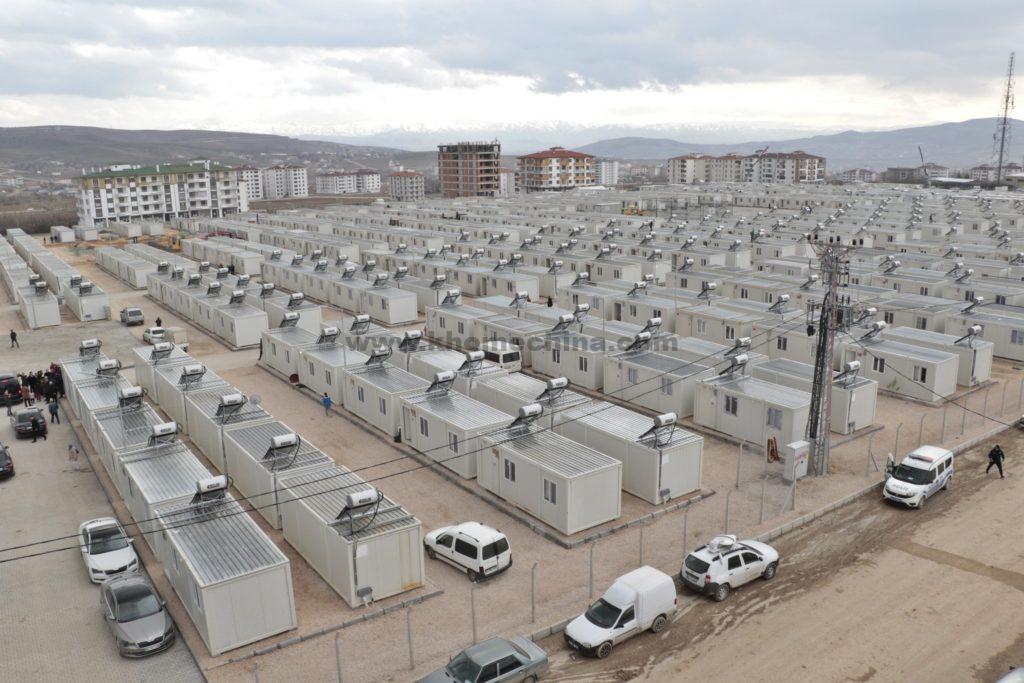

Project Show

Recent Blogs

SEND A MESSAGE